Department Functional Granular and Composite Materials

The department for functional, granular and composite materials addresses raw materials in powder and fiber form as well as handling and subsequent processes based upon them. Modelling and simulation is complementing experimental work both in laboratory as well as on microgravity platforms.

Granular matter by definition is an agglomeration of particles that are large enough for thermal motion to become insignificant and for dissipation to dominate the dynamics of particle collisions. The behavior of granular matter is relevant for many applications, for example in powder technology. Granular matter also serves as a model for the fundamental understanding of many-particle systems. The macroscopic behavior of granular systems is investigated by interweaving microscopic theories, numerical simulations and laboratory experiments. Research is focusing on understanding the macroscopic properties of granular matter from particle-particle interactions, microgravity and laboratory experiments for granular gases, liquids, and packed beds, as well as theory and experiments on granular rheology. Numerical simulation is also used as a tool to investigate fundamental predictions and to extend the otherwise inaccessible parameter space.

The understanding of granular matter has a direct impact on the development and production of functional composite or particulate materials.

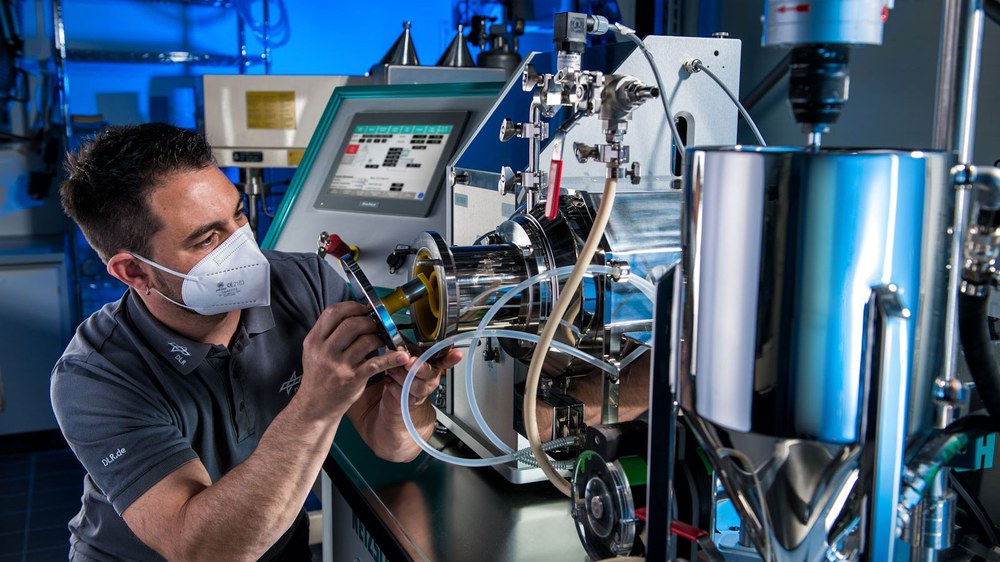

One R&D focus here is on oxide ceramic composite materials (OCMC), which are used as lightweight thermal protection systems in aircraft engines and reusable spacecrafts. In the field of OCMC, we are employing powders which are processed into dispersions of special rheology using state-of-the-art equipment such as an agitator bead mills and processed into fiber composites using various methods. In the field of particulate materials, we are working on oxide ceramic particles with high temperature stability and high sunlight absorption, which are used as absorber and heat transfer media in concentrating solar processes at temperatures of up to 1000°C. Particles made out of redox ceramics heated by solar radiation up to 1500°C enable specific chemical processes, such as the thermal production of so-called solar fuels. Sustainable ceramic materials, which preferably come from secondary raw material sources such as metal smelting, are being developed for new heat storage systems. A further R&D topic is the use of lunar material ("moon dust" or "regolith") as a raw material for future, locally producible relevant products for lunar missions and their infrastructure.

A new innovative approach is the use of quantum computers for the simulation of complex systems and materials, which we are pursuing in the frame of various projects of DLR’s Quantum Computing Initiative (QCI).