Department Tailored Metallic Materials and Processes

In order to speed up development times, reduce manufacturing costs and the weight of aerospace components and to increase functionality and performance, research is being conducted into metallic materials and structures, their manufacturing technologies and suitable joining processes. This includes, for example, alloys for drive technologies or high-temperature applications and light metals for structural lightweight construction. Bonding technologies, especially for structural bonding with other metal structures or fibre composites, are an enabler for use in structural lightweight construction.

Rapid Alloy Development

In this area, data-centred methods such as machine learning are being researched for the development and analysis of new alloys. In particular, the development and characterisation of lightweight and high-temperature alloys for the aerospace industry play a central role. The new alloys are developed and manufactured specifically for additive manufacturing processes with their high to very high cooling rates and tested for use on the ground or in space. The close link with the investigation of melting and solidification processes, processing and post-treatment methods, and microanalytical and material-mechanical characterisation allows comprehensive consideration to be made during the development of new materials.

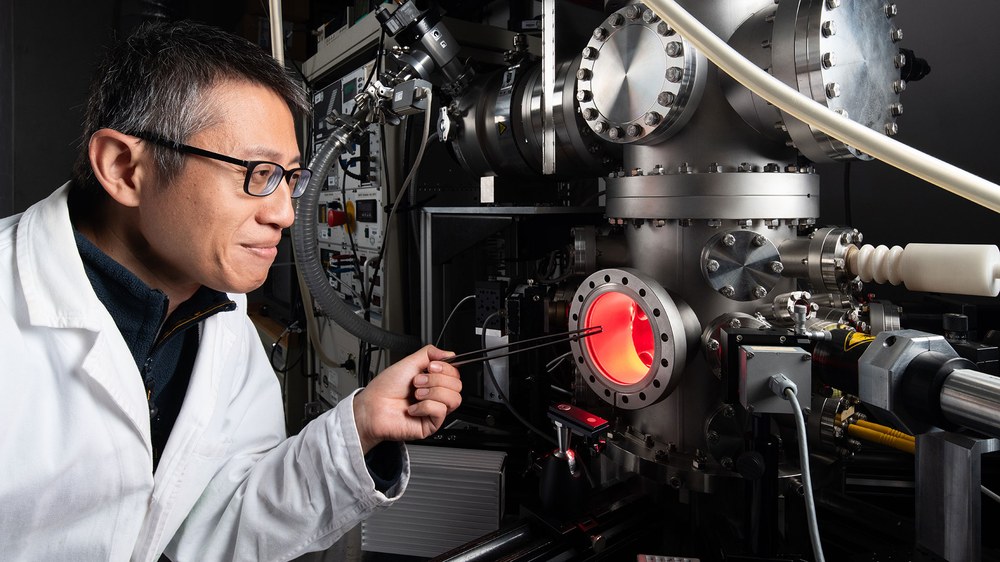

Melting Properties

The vast majority of structural materials of interest for applications are in a ‘solid’ state. However, their production, and usually also their processing, involves melting into a liquid state. The material and its properties are therefore created by the solidification process, in which the atoms generally ‘arrange themselves’. Research into melting properties is concerned with mass transport, relaxation phenomena and the thermophysical properties of liquid metals and oxides. The aim is to identify and understand the fundamental physical mechanisms that determine these properties in the liquid state and in disordered systems. These results are important information for large-scale simulations in material design, e.g. for predicting the formation of microstructures during solidification in casting processes and additive manufacturing, or the reaction behaviour between solid and liquid.

Solidification

A precise understanding of solidification processes and the underlying thermodynamics, nucleation and crystal growth processes is essential in order to develop new alloys, adjust material properties and optimise processing and recycling processes.

Detailed solidification experiments and material characterisation in the laboratory and at the synchrotron enable the department to gain this understanding. Solidification plays a central role in primary moulding processes such as casting technologies and additive manufacturing. The formation of the microstructure and any processing problems that arise can be traced back to the solidification and phase transformation processes, which allows targeted solutions to be derived through process control or alloy customisation.

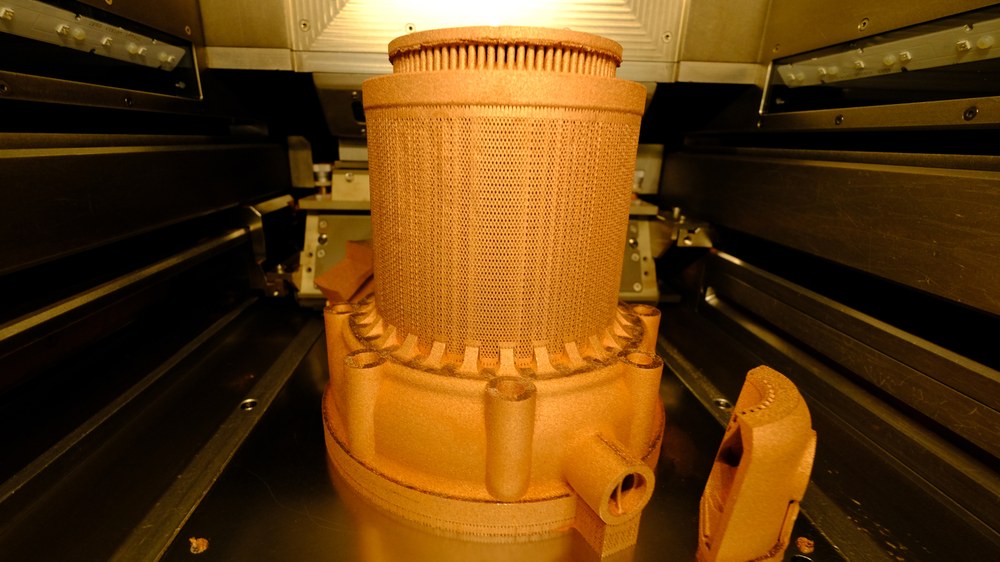

Additive Manufacturing of Metallic Components

Research and development in the field of metal processing is focussed on additive manufacturing processes. In addition to the development of new alloys that are specifically geared towards the metallurgical conditions of powder bed-based laser melting (PBF-LB/M or LPBF), laser-based powder deposition welding (L-DED/p) and wire deposition welding technology (L-DED/w), particular attention is paid to the alloys established in the aerospace industry for engine and structural applications. The expertise includes the development of processes and production chains, component manufacture, heat and surface post-processing as well as material and component characterisation.

Interface Research for Material Joining Processes and Hybrid Materials

Modern lightweight and functional designs are optimised multi-material designs that consist of different joining points with transitions from one material to another, or even another material class. The work in this area relates to the structural bonding of metal and fibre composite plastics or polymers, the material-to-material joining of different metal components and the welding or bonding of fibre composite plastic designs. The joining zones of soldered joints and composite materials are also part of the research work in this area.

Interface Research for Interlocking Joining Processes and Hybrid Materials

Modern lightweight and functional constructions are optimised multi-material designs that consist of different joining points with transitions from one material to another, or even another material class. The work in this area relates to the structural bonding of metal and fibre composite plastics or polymers, the material-to-material joining of different metal components and the welding or bonding of fibre composite plastic designs. The joining zones of soldered joints and composite materials are also part of the research work in this area.

User Support

Materials science research on board the International Space Station (ISS) is based on the Electromagnetic Levitator (EML; installed in the European Columbus module of the ISS) and the Materials Science Laboratory (MSL). Both experimental platforms are aimed at research in the areas of solidification, crystal growth and diffusion as well as the thermophysical properties of metals. The preparation, execution and evaluation of the first series of experiments in space are coordinated by the department within the DLR Microgravity User Support Centre.

Rapid development and characterisation of lightweight and high-temperature alloys for the aerospace industry

Optimised multi-material designs