Department Digitally Integrated Microstructure and Mechanics

Innovative products are not created by chance, but are based on intelligent material solutions. To ensure their reliability, safety and longevity, it must be possible to precisely predict the material behaviour under operating conditions. This requires an in-depth understanding of the physical processes and interrelationships in the material under various loadings.

We utilise and develop experimental and numerical methods on all relevant length scales, from the electronic structure through atomic and molecular relationships to the microstructure. The morphology of phases and interfaces as well as effects caused by the shape and surface properties of components also play a central role. Our focus is on high-performance materials that are characterised by high mechanical strength over a wide temperature range. With the help of data-driven methods, finite element (FE) simulations, artificial intelligence (AI) and quantum computing (QC) as well as the automation of our testing and analysis methods, we accelerate research of new materials and significantly shorten development cycles.

Understanding Material Behavior - Predicting Component Performance

Safety-critical components in the aerospace industry require reliable material concepts. The mechanical properties of a material are directly related to its internal structure. We analyse these structure-property relationships using theoretical models and experimental methods and derive evaluation concepts from them. Our research focuses in particular on fatigue properties and fracture mechanical behaviour. One focus is on the three-dimensional simulation of crack propagation in components. Well-founded service life predictions make a decisive contribution to sustainable and resource-saving lightweight construction. These issues are particularly relevant for the safety of critical components, such as those used in the aerospace industry.

By combining classic testing technology with high-resolution digital image correlation, robotics and AI, we are setting new standards in experimental mechanics. Self-driving labs enable the automated generation of large data sets in order to uncover complex correlations. These findings are also crucial for the virtual certification of the next generation of aerospace structures and represent a significant step towards safer, more efficient and more powerful technologies.

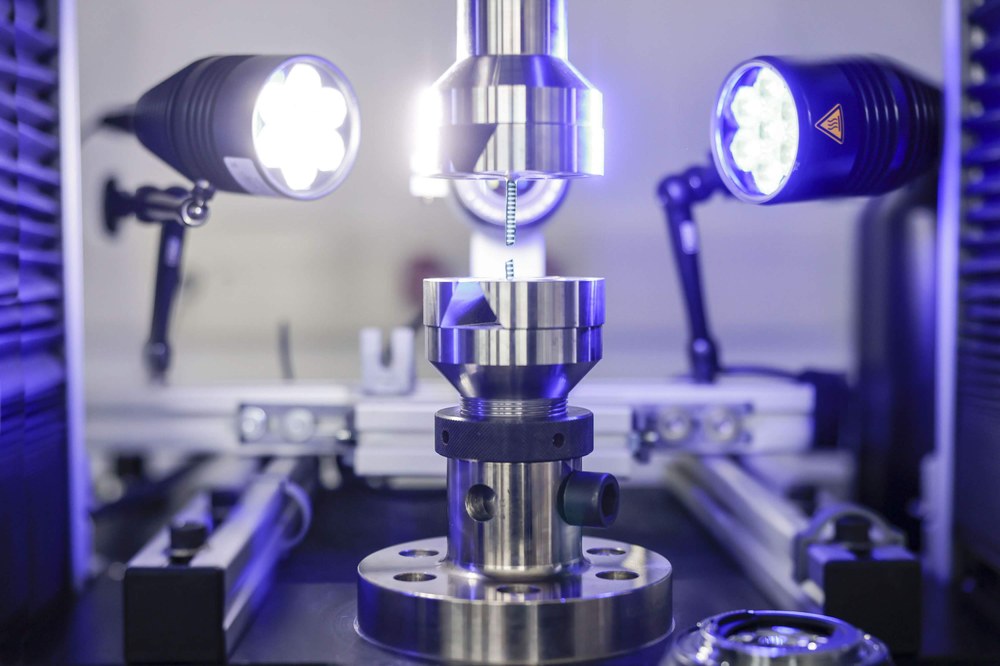

Materials Mechanics Testing - Precision Under Extreme Conditions

Reliable material data is the basis for evaluating the behaviour of parts and components under real operating conditions. We therefore characterise high-performance materials under realistic operating conditions and develop modern, digitalised testing methods. Servo-hydraulic, electromechanical and resonance testing machines with forces from 1 to 1000 kN are available for this purpose. A biaxial testing machine also allows the testing of cruciform specimens under biaxial loading conditions. Our range of services includes

- Mechanical characterisation (tensile, bending, compression tests)

- Fatigue analyses (Wöhler tests, crack propagation tests, fracture toughness)

- Creep tests under long-term load

- Tests under extreme conditions (temperatures from -196°C to 1400°C, corrosive environments)

- Digital image correlation from the micro to the macro level

In our research, we focus on high-temperature and lightweight materials that are used, for example, in jet engines or efficient lightweight constructions. We develop the latest imaging methods, robot-assisted automation and digital workflows to record and analyse test data quickly and precisely. On this basis, we create comprehensive material cards. All data is stored sustainably in a structured data management system in accordance with the FAIR principle (Findable, Accessible, Interoperable, Reusable).

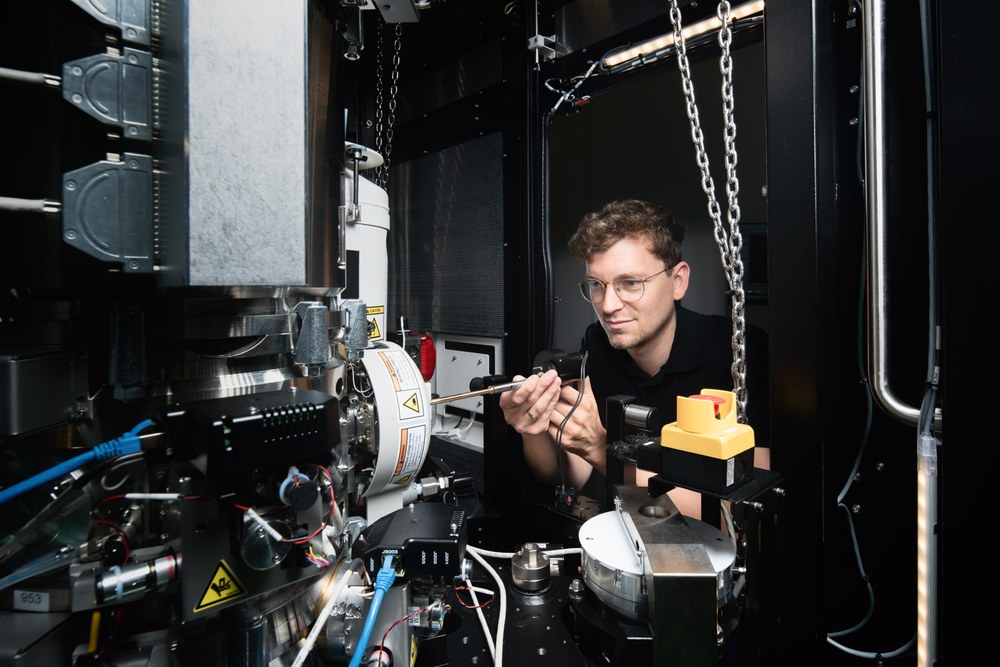

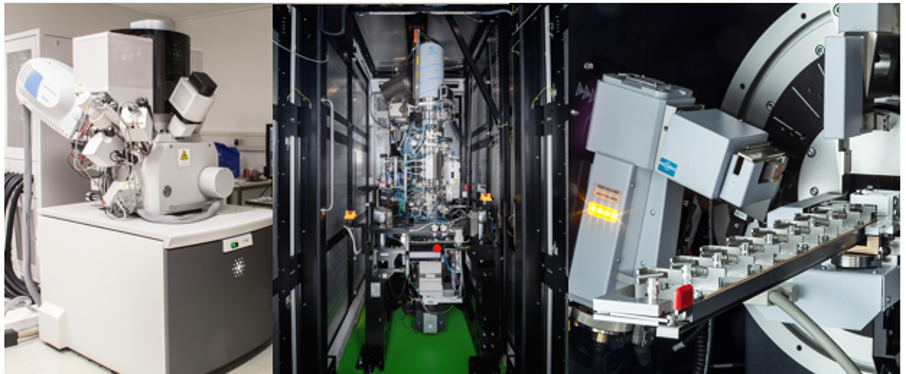

Getting to the Bottom of Materials - Analyses down to the Atomic Scale

Modern materials are characterised by complex microstructures made up of different elements and phases. The basis for understanding material behaviour is the characterisation of these microstructures, from the atomic structure of the phases and interfaces to the classical microstructure and discontinuities in components. We develop methods to efficiently characterise the microstructure of materials from the atomic level to the component. We use a variety of diffraction methods such as X-ray and electron diffraction, as well as imaging microscopy methods from the fields of light microscopy, scanning electron microscopy (SEM) and transmission electron microscopy (TEM). These are supplemented by spectroscopic techniques such as energy dispersive X-ray spectroscopy (EDX) and electron energy loss spectroscopy (EELS). To interpret the analysis results, we rely on data-driven evaluation procedures and machine learning methods. This allows us to identify complex correlations between microstructure and material properties, which are decisive for the functional performance of components.

Cross-Scale Modelling - Digital Approaches for new Materials

Technical products have to fulfil a wide range of requirements, in particular specific physical properties, a long service life, resource efficiency and cost-effectiveness. To accelerate the development of new material solutions, we rely on artificial intelligence (AI) to analyse high-dimensional data sets. We combine phenomenological models with experimental results to develop robust prediction models for material-related properties. The necessary understanding of fundamental material properties, from electronic structure to macroscopic properties, requires simulations on all relevant scales. This is why we develop advanced simulation and optimisation methods using quantum computing, quantum annealing and high-performance computers. Together with our research partners, we enable faster, more precise and more efficient development of sustainable products for the aerospace industry.

Core Expertise

Prediction of component performance

Materials mechanics testing and characterisation of high-performance materials

Efficient, precise and automated material development