Parabolic troughs for solar process heat in the low to medium temperature range

Concentrated solar thermal energy using parabolic trough collectors offers considerable potential for the provision of renewable heat. Parabolic trough technology has been established for decades, is technologically mature and is used successfully worldwide. Recent studies also show that it can make a significant contribution to the sustainable heat transition in Germany. Here too, it is capable of supplying large amounts of energy with controllable operating temperatures of 100 to over 400 degrees Celsius and can be used economically in district heating and as process heat in many areas of industry. Short- or long-term heat storage allows solar heat to be used even when there is little or no sunshine. This increases the proportion of heat provided by solar energy (increase in solar coverage). Hybridising a solar thermal system with other renewable sources extends the coverage to provide renewable process heat all year round.

From component development to industrial application

The DLR Institute of Solar Research supports manufacturers in the development of components and collector systems, while also conducting research into its own innovative technologies in collaboration with industry partners. Both parabolic trough and Fresnel technology are mature and therefore available. This is demonstrated by large-scale projects such as the solar process heat supply with a parabolic trough field at Heineken in Seville, with a thermal output of approximately 30 megawatts and an annual coverage ratio of approximately 50 per cent. However, further cost reductions through new technologies are necessary for faster market development.

Optical qualification procedures support the development of components and collectors. Furthermore, test benches are used to determine characteristic data in accordance with standards such as ISO 9806, which provide information about efficiency and expected heat yield and, where applicable, approaches for optimisation.

Concentrating collectors are available in various designs, which differ in terms of efficiency and price. The German Aerospace Center (DLR) advises users on the advantages and disadvantages of different technologies and the expected thermal yields, taking into account location-specific meteorological data, including time-resolved data on solar radiation, temperature and wind speed. To this end, results from generally available calculation tools such as ScenoCalc (tool for solar thermal systems in heating networks) and greenius are used.

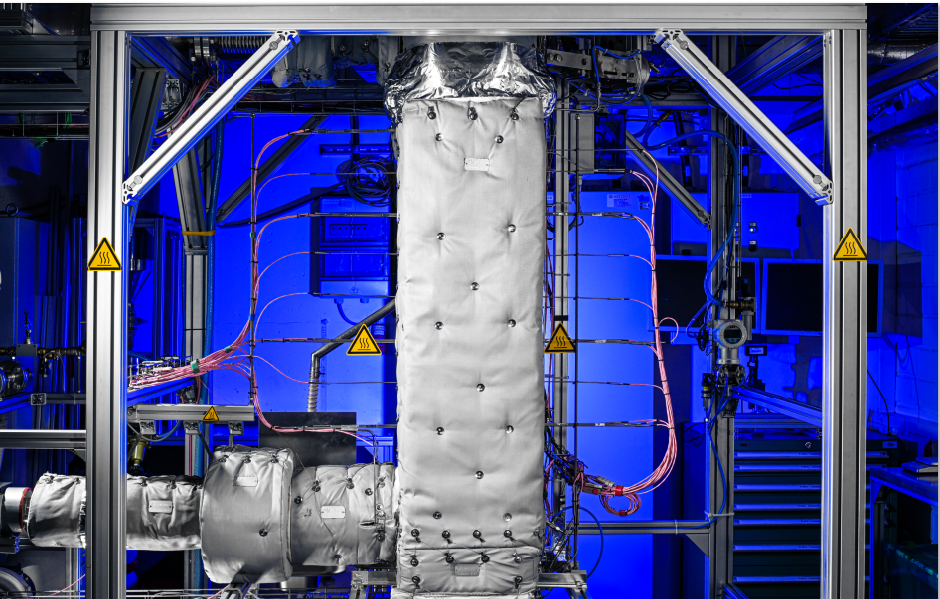

Various heat transfer media are used in parabolic trough applications. Possible heat transfer media include thermal oils (e.g. silicone oils, synthetic or mineral oils) and molten salts. In addition, pressurised water or water/steam systems can be used, which operate either in the saturated steam process or with superheated steam. The Fluid Systems research group tests and demonstrates their use in order to minimise risks for commercial application. This also includes the integration of solar heat, i.e. the transfer of heat from the solar field to the consumer, possibly with the involvement of storage facilities.

Advantages of parabolic trough technology for industrial heat supply

As an integral part of the future heat supply for industry, parabolic trough technology also offers the following benefits for Germany:

▪ Immediately available key technology for heat supply

▪ High local added value

▪ High economic efficiency

▪ Immediate and long-term emission-free operation

▪ High security of supply

▪ Long-term price stability

▪ Relief for the electricity grids and reduction of supply gaps for renewable

electricity

▪ European supply chains

Parabolic trough collectors therefore represent another option for low-carbon heat supply in industry and district heating. Due to their high heat yield and low investment costs, they are also particularly economical.

Solar tower power plants enable high-temperature applications

One of the challenges of the energy transition is to convert the high heat demand for energy-intensive industrial high-temperature and fuel production processes from fossil fuels to renewable energies. High-temperature applications include processes that typically require a constant heat supply of over 500 degrees Celsius. Since renewable energy sources such as solar and wind fluctuate and are not continuously available, a constant heat supply based on these sources requires thermal or electrical storage. In many regions, concentrating solar technology using solar tower power plants can be the solution, as it provides high-temperature heat of up to 1,000 degrees Celsius or even higher, which can be stored relatively easily and cost-effectively.

Here is a selection of high-temperature applications in different temperature ranges where the high-temperature solar receivers can be used in an indirect or direct solar heating process:

Temperature range 500–800 degrees Celsius:

- Drying processes

- Gypsum production

- Distillation processes

Temperature range 800–1,100 degrees Celsius:

- Pyrolysis

- Calcination

- Metal melting

- Ore roasting

Temperature range above 1,100 degrees Celsius:

- Calcination

- Ceramic industry, iron reduction, gas smelting

- H₂O splitting for hydrogen production

Solar thermal systems for flexible and efficient heat generation

For solar-powered systems, storage is an essential element in achieving high plant utilisation and reducing the amount of expensive additional heat required for 24/7 operation of high-temperature applications. Concentrating solar technologies cover a wide temperature range and can deliver heat up to 1,500 degrees Celsius. They can supply heat to a variety of industrial processes. Parabolic trough power plants are not only interesting for sunny regions, but can also be used profitably in temperate zones such as Central Europe, depending on the heat demand. Solar thermal power plants only reach their full potential in sunny regions.