Project E²NGEL: Precious metal-free electrodes as the key to scaling up alkaline electrolysis

With the E²NGEL project - Precious metal-free electrodes for the next generation of alkaline electrolysis - our institute, together with industry, is making an important contribution to the implementation of the National Hydrogen Strategy. The aim of the project is to overcome a key technological and economic hurdle in hydrogen production and thus provide sustainable support for the large-scale utilisation of alkaline electrolysis.

Importance of precious metal-free electrodes

Alkaline electrolysis has been an established and robust technology for hydrogen production for decades. However, costs, material availability and security of supply are increasingly coming into focus for the industrial ramp-up. Precious metals are a limiting factor here: They are cost-intensive, subject to high price volatility and are considered critical raw materials.

Dispensing with precious metals enables a significant reduction in electrode costs and at the same time minimises the risks associated with these materials. When scaling up electrodes and large-scale production, the costs and availability of the base metals used are becoming increasingly important - both for the stack and for the entire electrolyser.

Technical challenges and solution approach in the E²NGEL project

Previous approaches for precious metal-free electrodes could not compete with precious metal-based systems in terms of efficiency, cell voltage and achievable current densities or showed deficits in service life. Although various coating processes have been investigated in the past, it was not until the E²NGEL project that an overall optimised electrode concept was developed.

The decisive factor here was the targeted combination of optimised starting materials, a further developed coating process and an adapted post-treatment of the electrodes. The electrode technology has been developed and refined at DLR over many years and has now been implemented on an industrial scale. The details of this industrial development are the responsibility of the project partners; further technical insights were presented by Dr Karsten Lange (Rheinmetall) and others in August as part of the “Energy Research Networks”.

Performance and long-term stability

In terms of performance and overvoltage, the electrodes developed in the project show results that are comparable with published precious metal-based systems. Although literature data is only comparable to a limited extent due to different cell constructions and components, the overall performance of the E²NGEL electrodes is clearly competitive.

The long-term stability is also in line with expectations: The observed degradation rates are in the range of the precious metal systems described in publications.

Test periods and operating experience

At the DLR, individual electrodes were analysed electrochemically over more than 1,000 operating hours. Results from stack operation are also available: At McPhy, characteristic curves were presented after around 50 days of operation, corresponding to around 1,200 operating hours. These results were presented at the 8th Industry Workshop Advanced Alkaline Electrolysis at IFAM Dresden.

Contributions of the project participants

The E²NGEL project is based on close and proven co-operation between research and industry along the entire value chain of alkaline electrolysis.

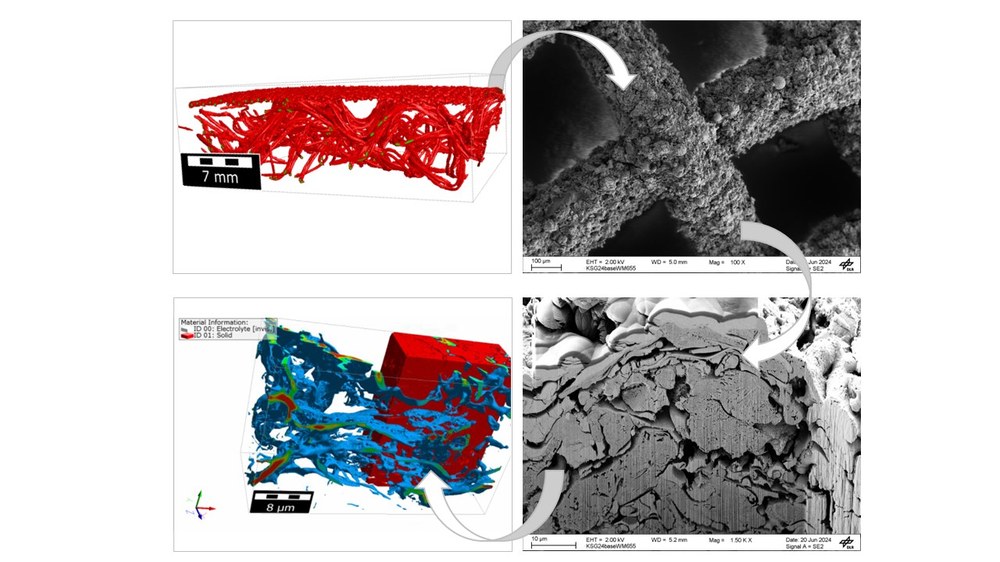

Our institute was responsible for the scientific support and the structural and electrochemical evaluation of the precious metal-free electrodes. This included the design of suitable test methods, experimental characterisation under realistic conditions and the analysis of performance curves, overvoltages and degradation behaviour with a particular focus on long-term stability. In addition, DLR's electrode coating processes were further developed and the project's most powerful hydrogen electrodes were prepared at DLR.

Rheinmetall was responsible for the material development and industrial production of the electrodes. Here, both the starting materials and the coating and post-treatment process were further developed in order to realise precious metal-free electrodes with industrially relevant performance for the first time.

Integration into alkaline electrolysis stacks and operation under realistic conditions took place at McPhy. The tests carried out there provide important insights into the transferability of the laboratory results to large-scale operation and the suitability of the electrodes for dynamic operating modes. The work at McPhy Germany was led by Dr Matthias Neben and these activities have since been merged into John Cockerill Hydrogen.

Outlook

E²NGEL shows that precious metal-free electrodes are a powerful and stable alternative to established systems. The project thus makes an important contribution to reducing costs and scaling up alkaline electrolysis on an industrial scale - and thus consistently follows a proven approach in applied energy research: from the material to the cell to the industrial electrolyser.

Contact

Prof. Dr. rer.nat. K. Andreas Friedrich

Dipl.-Kff. Sabine Winterfeld