TEMPEST

The simulation environment TEMPEST (Transient Electrochemical Models for Process and Energy Systems) of the DLR Institute of Engineering Thermodynamics in Stuttgart offers the possibility of transient simulation of process engineering systems with electrochemical reactors. The structure of the environment allows the development of operating and control strategies for systems and reactors by using models of reactors from different manufacturers or generic architectures.

Research objectives

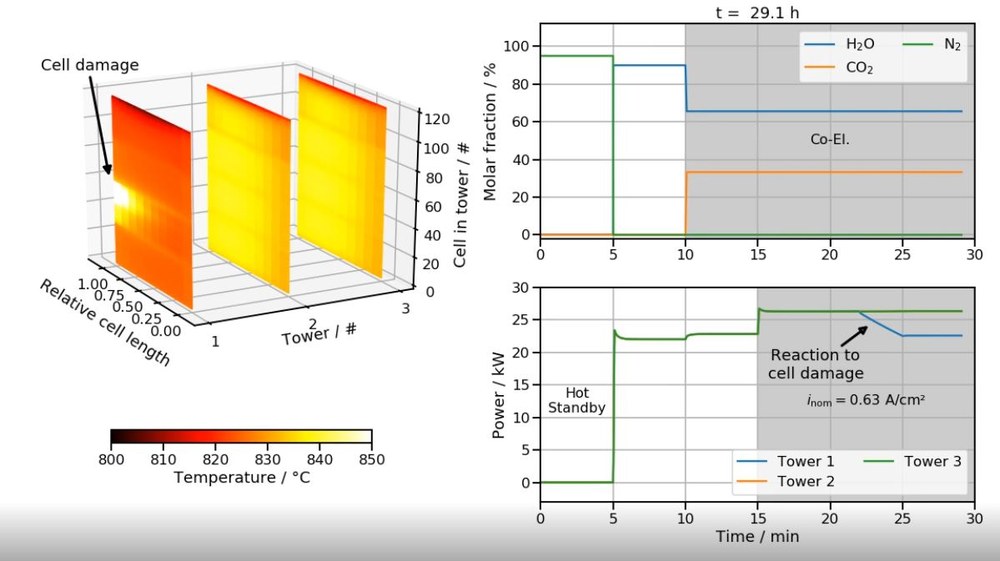

TEMPEST is used to investigate the stationary and dynamic behavior of process engineering systems with electrochemical reactors. The two main areas of application are the development of control and operating strategies and the investigation of scaling strategies. In both cases, the distribution of critical parameters within cells and reactors (temperature, current density, flow, composition) is analysed.

Specific applications of the simulation framework include, for example, the investigation of a hybrid system consisting of reactors with solid oxide fuel cells (SOFC) and batteries for a maritime powertrain as well as the direct integration of volatile renewable electricity into electrolysis processes. In both cases, the effects of fluctuating electrical power on the reactors are examined and which control and operating strategies can be used to increase efficiency and longevity.

Furthermore, a strong synergy with experimental studies is sought. On the one hand, the HORST and GALACTICA test benches provide important parameterization and validation data for modeling. On the other hand, accompanying simulation studies enable low-risk and targeted experimental investigations. In addition, the validated models can also be used to analyse operating areas that go beyond the experimental possibilities.

Details about the simulation environment

- The modeling language used is Modelica®

- The environment is adaptable to electrochemical reactors with different technologies. These include electrode, electrolyte and metal-supported solid oxide cells in planar, tubular or segmented designs with co-, counter- or cross-flow gas guidance. In addition, cell models for alkaline water electrolysis were developed, which are currently being further developed into reactor models.

- The level of detail of the models can be adjusted depending on the examination goal. Electrochemical reactors can be depicted as 0D models or as detailed 1D+1D models including representation of thousands of cells. Furthermore, you can choose between detailed calculations of the electrochemical loss mechanisms and simplified loss functions.

Exemplary result

TEMPEST_Simulation

Your consent to the storage of data ('cookies') is required for the playback of this video on Quickchannel.com. You can view and change your current data storage settings at any time under privacy.

Projects

· SynLink

· HTCoEl

· SWITCH

· NAUTILUS

· Helenus

· H2Mare

· H2Giga-AEL4GW

· eModule

Publications

S. Srikanth, M. P. Heddrich, S. Gupta, and K. A. Friedrich, Transient reversible solid oxide cell reactor operation - Experimentally validated modeling and analysis. Applied Energy, 2018. 232: p. 473-488. doi: 10.1016/j.apenergy.2018.09.186

M. Tomberg, M. P. Heddrich, F. Sedeqi, D. Ullmer, S. A. Ansar, and K. A. Friedrich, A New Approach to Modeling Solid Oxide Cell Reactors with Multiple Stacks for Process System Simulation. Journal of the Electrochemical Society, 2022. 169(5). doi: 10.1149/1945-7111/ac7009

M. Tomberg, M. P. Heddrich, S. A. Ansar, and K. A. Friedrich, Operation strategies for a flexible megawatt scale electrolysis system for synthesis gas and hydrogen production with direct air capture of carbon dioxide. Sustainable Energy & Fuels, 2023. 7(2): p. 471-484. doi: 10.1039/d2se01473d