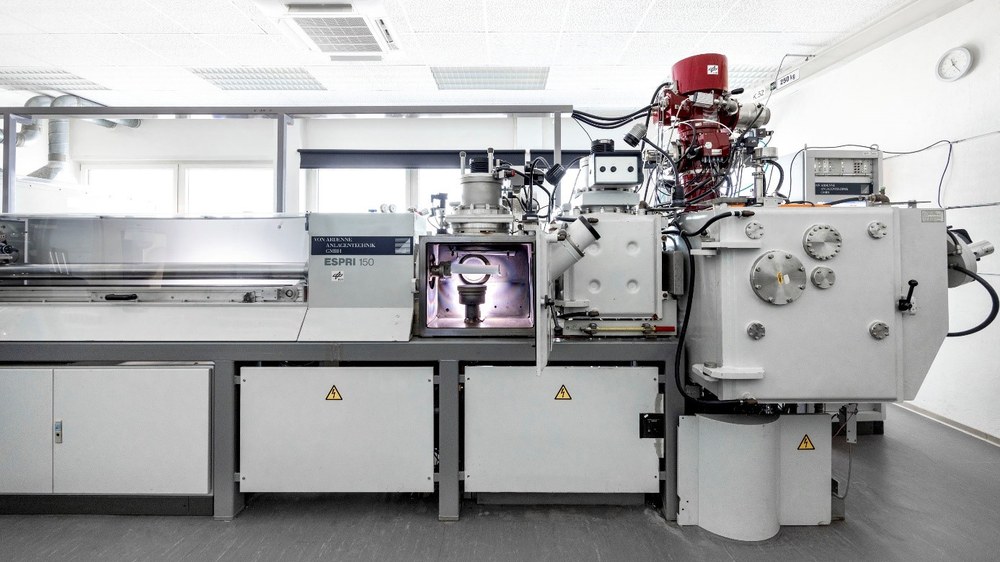

Electron Beam Evaporation System (EB-PVD) ESPRI 150

A 150 kW double crucible system (EB-PVD "ESPRI") is installed in the Institute of Materials Research. This system enables the simultaneous evaporation of different materials. The computer-controlled, quickly deflectable electron beam (“jumping beam”) enables both parallel and sequential evaporation from the two crucibles, resulting in metallic and ceramic layers in a monolithic, graded or even multi-layer arrangement in the range of a total layer thickness of up to a few 100 µm at deposition rates of up to 20 µm/ min.

The system consists of the classic 3-chamber design and has various modules, e.g. for pre-treatment such as annealing, pressure and gas mixture flow control, in-situ measurement of sample temperature and layer thicknesses, variable vacuum generation and variable crucible geometry as well as digital data recording.

A wide variety of sample holders, such as planetary gears for cylindrical samples and small turbine blades or flat sample holders, enable flexible substrate geometries. Cameras allow the evaporation process to be observed and recorded and thus help to optimize the process parameters to improve the layers. Process parameters of commercial EB-PVD coating equipment can be fully reproduced.

Contact

Prof. Dr.-Ing. Uwe Schulz