Joint project OptiSysKom

Gas turbines make an important contribution to the optimisation of complex overall energy systems with high demands on flexibility, security of supply and economic efficiency. In addition to flexible operation modes, gas turbines offer additional options for supporting sector coupling and for the use of alternative fuels from power-to-X applications (e.g. increasing proportions of hydrogen from renewable energies, synthetic methane, etc.). They therefore not only ensure safe and reliable power generation, but also contribute to reducing greenhouse gas emissions and nitrogen oxides due to more efficient fuel utilisation.

However, the required flexibility of today's turbomachinery is accompanied by higher wear, major efficiency losses in the partial load range and a shorter service life. In the "OptiSysKom" project, the aspects of the effects of the operation of turbomachinery in combination with renewables with a view to service life and efficiency, which were started in previous research projects of the Turbo working group, are to be continued in greater depth. The sub-research projects proposed in this outline are intended to upgrade turbomachinery for the energy transition, as "gas-fired power plants have a high flexibility potential and can help to balance out fluctuating generation from renewable energy plants" ... "Fuel and load flexibility are therefore important research goals, especially for gas-fired power plants, in order to be able to provide system services." (1)

(1) Federal Gazette: BAnz AT 18.10.2018 B - "Innovations for the energy transition", Section 3.10 Thermal power plants

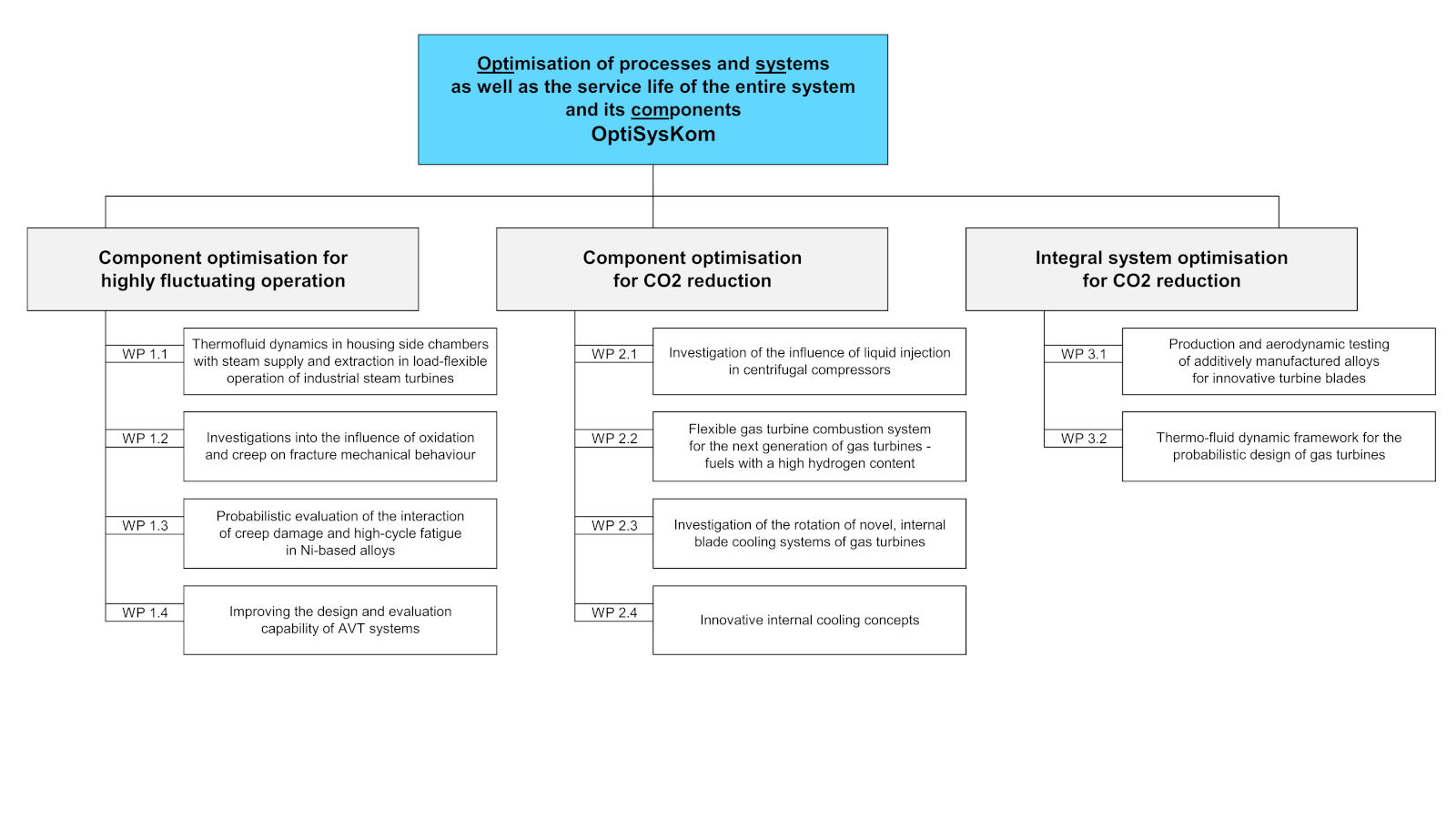

Work packages

The work packages of the OptiSysKom joint project address different levels of optimisation of processes and systems for adapting turbomachinery to the conditions of the energy transition. On the one hand, the focus is on optimising the interaction of the components and, on the other, on optimising the individual components. The thematic focus is on two aspects: (1) Consideration of the increasingly fluctuating, i.e. performance-changing, operation of the turbomachinery and its influence on the service life of the components in particular and (2) Reduction of greenhouse gas emissions by optimising the components and the operation of the system.

WP 1: Component optimisation for highly fluctuating operation

In this work package, the focus is on realising the longest possible service life despite high cyclical loads on the turbomachinery components. Due to the changes in operating modes compared to the past, the same service lives must now be achieved under different boundary conditions. This is where the work comes in, in order to determine new methods for evaluating and designing the components.

WP 2: Component optimisation for CO2 reduction

Components for CO2 reduction are being optimised here. In the combustion chamber, the focus here is on gradually replacing natural gas with hydrogen and increasing the cycle temperatures. At the same time, innovative cooling concepts are being developed for the thermally highly stressed components in the high-pressure turbine, which can be realised through additive manufacturing.

WP 3: Integral system optimisation for CO2 reduction

In this work package, methods are being investigated that optimise the interaction of the components in the overall system.

Project structur plan

Facts and figures

Volumen

7.935,6 k€

Project duration

01.07.2020 - 31.12.2023