Joint project TurboGrün

The intention to massively expand renewable energy conversion based on wind and solar has a major impact on the existing power plant fleet, which must be adapted to the volatile nature of renewable energy sources. In addition to the energy efficiency on the consumer side envisaged in the Energy Research Act, the targets set by the Federal Government can only be achieved if sectors such as transport, households and industry are also electrified to a greater extent in order to make them accessible to renewable energy sources.

The following conclusions can be drawn from the further expansion of renewable energy conversion plants:

Further expansion of renewable energies only makes sense if storage capacities are significantly increased at the same time. This must be done on a scale that far exceeds the technically mature storage technologies available to date (pumped storage; batteries). In addition to mechanical storage (LAES; CAES) and thermal storage, in which turbomachinery is used without exception for new cycle processes, this also includes chemical power-to-gas storage.

Conventional power plants must be able to absorb the fluctuations of renewables by providing reserve energy in order to deliver "power on demand" and stabilise the grid. This means that the power plants and their turbomachinery must have maximum operational flexibility.

In addition to the generation of electricity for all sectors, the generation of heat for industrial applications and for the regional supply of district heating networks plays a key role. The use of CCGT and CHP plants means that plants with the highest levels of efficiency and fuel utilisation rates are available for this purpose.

Hydrogen produced using renewable energies will form the basis for the production of climate-neutral "green" fuels for the provision of high-energy fuels, for example for aircraft engines and ships. Ultimately, all end consumers - and therefore also thermal power plants based on gas turbines - should be able to run on a mixture with a high hydrogen content ("H2-ready").

MAN Energy Solutions SE

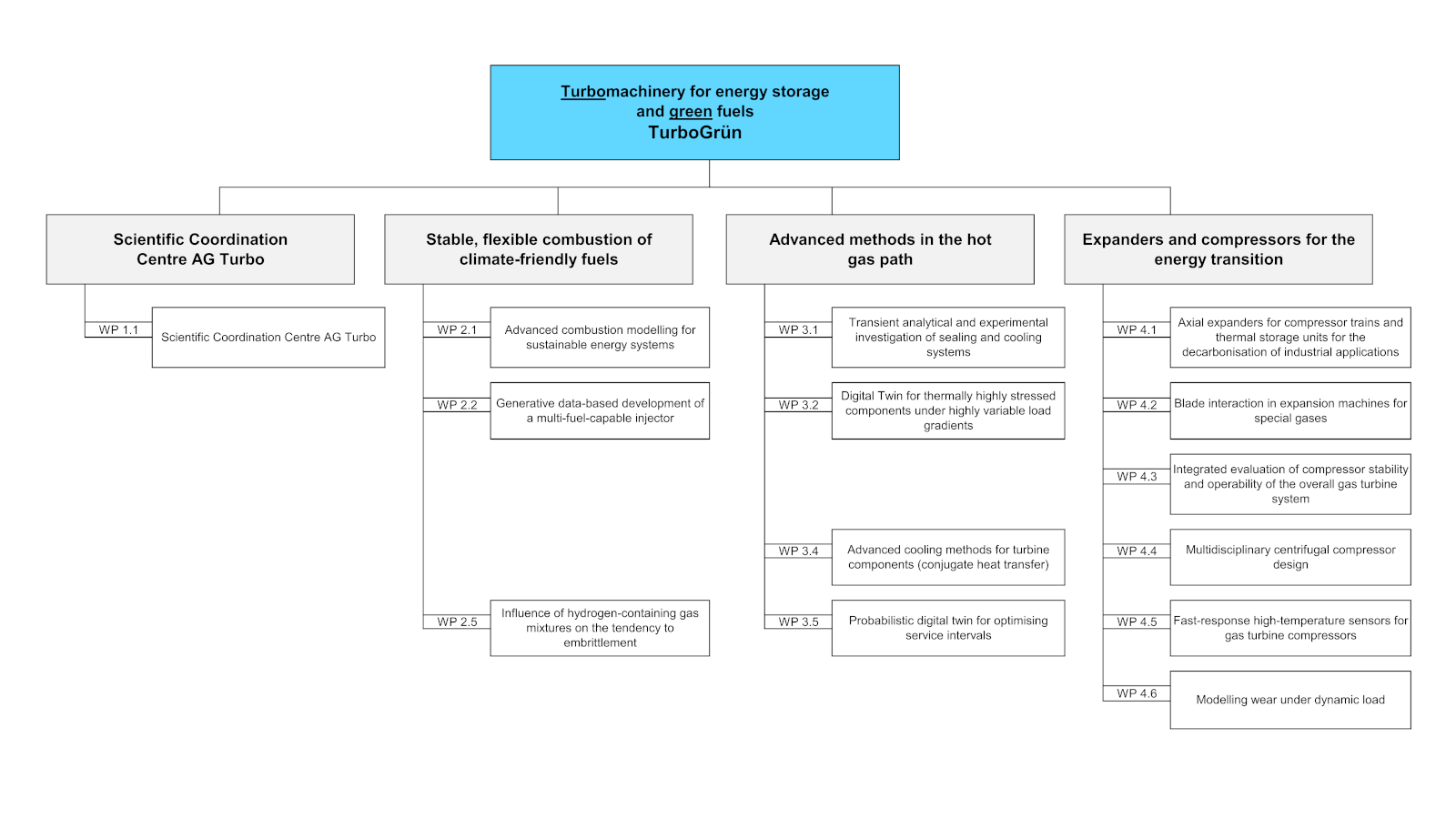

Work packages

The joint project is divided into thematically overarching work packages in which the development of turbo components for different areas of application in the new energy mix is being driven forward. The work of the TurboGrün joint project contributes to fulfilling the objectives of the 7th Energy Research Programme "Innovations for the Energy Transition".

WP 1: Scientific Coordination Centre AG Turbo

Administrative liaison with Project Management Jülich and the Federal Ministry of Economics and Climate Protection (BMWK) to ensure the necessary flow of information between the relevant specialist departments, Project Management Jülich, the programme management, the project managers, lead managers and members of the collaborative research project.

WP 2: Stable, flexible combustion of climate-friendly fuels

The work package "Stable flexible combustion of climate-friendly fuels" is dedicated to the combustion of hydrogen in pure form or as an admixture in natural gas and closes the chain to renewable energies in that the production of so-called green hydrogen by electrolysis means sustainable storage of excess electricity from renewable energy plants. The focus is on the development of robust and emission-reduced burners for gases with a high hydrogen content. The aim of the overarching work package is to upgrade gas turbine-based plants in the energy supply and transport of hydrogen-containing fuel gas mixtures for a hydrogen content of up to 100%.

WP 3: Advanced methods in the hot gas path

The "Advanced methods in the hot gas path" work package focuses on optimising the cooling air flow in order to ensure maximum reliability and efficiency. Among other things, the use of state-of-the-art production technologies (additive manufacturing) is also assumed. The development of digital twins based on probabilistic methods enables the optimisation of service intervals in order to avoid unnecessary downtimes. Methods for the analytical prediction of the service life of thermally highly stressed components are also being developed for this purpose. The utilisation of the results of this work package will lead to the economic operation and a high availability rate of gas turbines in a defossilised energy industry.

WP 4: Expanders and compressors for the energy transition

The "Expanders and compressors for the energy transition" work package is dedicated to compressors and expansion components for applications in storage processes for the future energy infrastructure dominated by renewables and in processes for the synthetic production of climate-neutral fuel gases. For turbines and expanders used in thermal storage cycle processes, the focus is on expanding the design system for special gas mixtures in the heating and cooling cycles. Among other things, special sealing measures must be taken to prevent the process gases from escaping into the environment. Radial compressors of the future will be calculated and designed using newly developed multidisciplinary design methods. Finally, integrated evaluations of compressors are considered with regard to stability and operability in the overall system and contributions are made to improved measurement technology.

Project structure

Facts and figures

Volumen

14.059 k€

Project duration

01.07.2021 - 30.06.2025

BMWK