Saving fuel and reducing emissions with shorter engines

The transformation of aviation towards more greener flying is underway. Research, industry and business are working together on numerous technologies to reduce the climate impact of aviation. In the field of propulsion technology, in addition to new energy sources and revolutionary propulsion solutions, the further development of advanced conventional engines plays a central role in achieving the EU's ambitious climate targets. One promising approach is to shorten the engine. The advantage is that the engine becomes lighter and uses less fuel. Lower fuel consumption means lower emissions.

Exploiting potential by redesigning the inter compressor duct

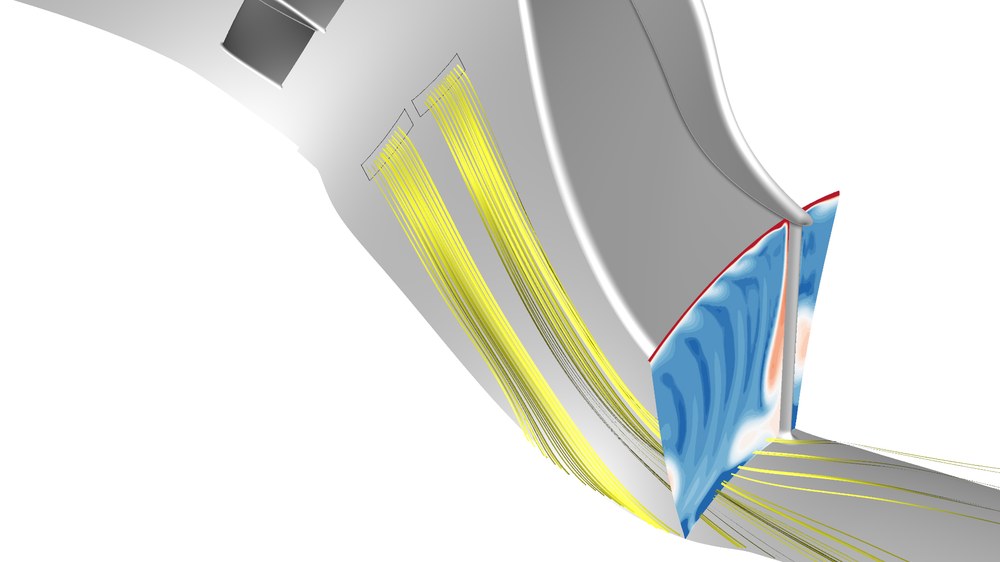

One way to shorten the engine is to redesign the inter-compressor duct (ICD). This duct connects the low-pressure compressor to the high-pressure compressor and directs the mass flow to the lower radius of the high-pressure compressor. Reducing the overall length of this duct saves weight and fuel, but makes the flow susceptible to unwanted and highly lossy separations. To prevent these separations, the Institute of Propulsion Technology at the German Aerospace Center (DLR) is together with the Technical University of Berlin and NAVASTO GmbH investigating the testing of active flow control in highly shortened intercompressor ducts.

Project RDuct

Participants: DLR-Institute of Propulsion Technology, Navasto GmbHTU Berlin

Running Time: End of 2024

BMWE