Optimisation Framework AutoOpti

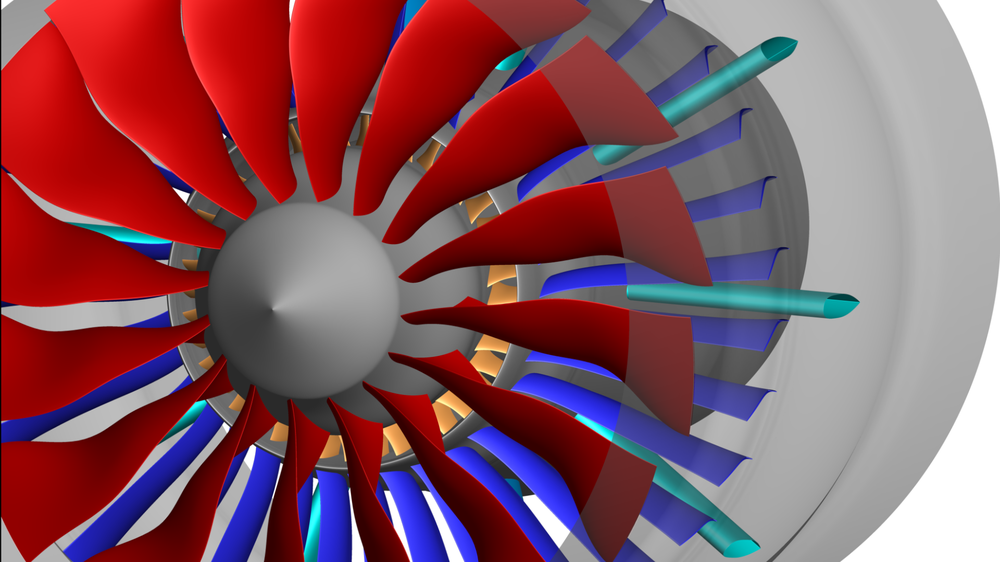

At the Institute of Propulsion Technology, we are developing an integrated numerical design system for the aeromechanical design of turbomachinery components. AutoOpti has reached a high level of maturity and is being used in industry.

The AutoOpti software package for automated multidisciplinary optimisation of turbomachinery components is used in the field of turbomachinery design. The application ranges from two-dimensional profile aerodynamics to three-dimensional multidisciplinary optimisation of multi-stage configurations. The core of the optimisation algorithms for aerodynamics, mechanics, aeroelastics and acoustics is based on a parallelised, asynchronous evolution strategy that allows the simultaneous improvement of several objective functions and the fulfilment of many constraints. This enables robustness to the optimisation process and the ability to overcome local minima.

Response surfaces for industrial applications: Gaussian processes and neural networks

The moderate convergence speed is raised to a level necessary for industrial and research practice by hardware-related acceleration methods and in particular by response surfaces (metamodels or surrogate models). The response surfaces (Gaussian processes neural networks) can also take into account gradient information of the target functionals, a prerequisite for the effective use of adjointTRACE in the process chain. The use of simulations of different quality levels is also supported by a multi-fidelity approach.

Database-supported approximation of target functionals and design parameters

Gaussian processes and/or neural networks approximate the relationships between target functionals and free design parameters on the basis of the results available in the database. A temporary optimisation is then carried out on these response surfaces and only the most promising data sets are transferred to the numerically complex process chain and are then available to the replacement models as additional training samples once they have been evaluated. This automatically improves the quality of these models.

Identification of the design with the maximum expected optimisation progress

During the temporary optimisations on the models, a new point in the design space is sought which, together with all designs still under evaluation, maximises the expected volume gain compared to the current Pareto front. Using this criterion, the data set with the maximum expected optimisation progress can be identified among the data sets with the same Pareto rank. In all adjustments, care is taken to ensure that the online controllability of AutoOpti, such as the modification of objective functions, constraints and limits of free parameters during an ongoing optimisation, is maintained and further improved. AutoOpti has now reached a high level of maturity and is being used successfully in several industrial companies