CoBra

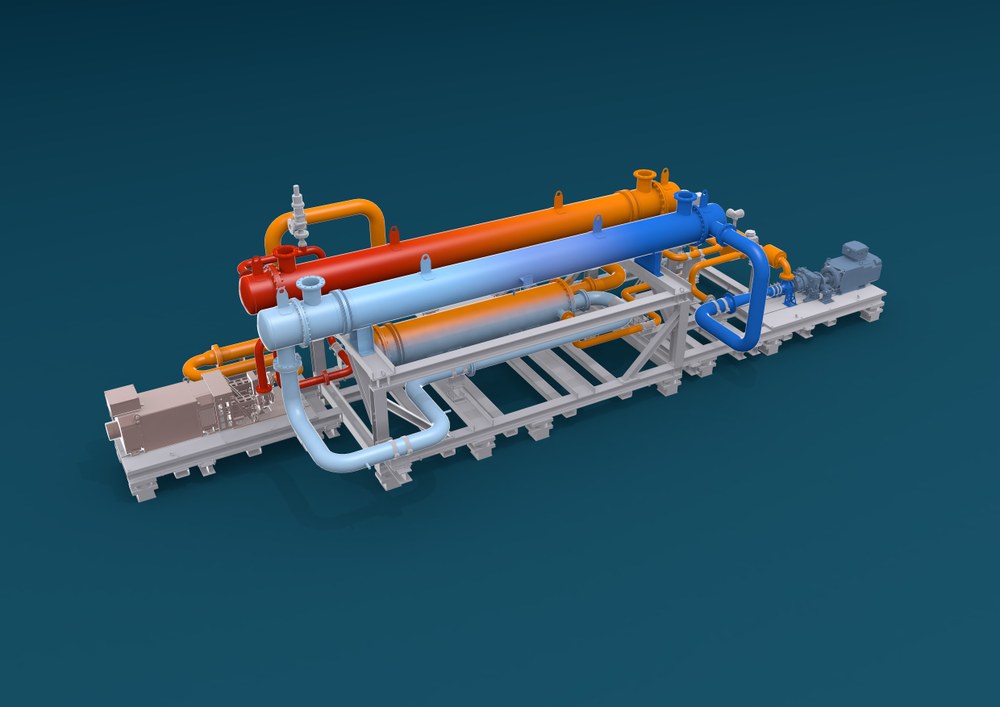

The CoBra test facility is a demonstration platform for high-temperature heat pumps and their components that works according to the Brayton process and uses air as a working medium. The name CoBra is derived from the terms Brayton and the plant location Cottbus. The CoBra consists of one main and two secondary circuits and is designed to provide process heat at temperatures of up to at least 300 °C and process cooling down to -40 °C. The system capacity is limited by the compressor system used in the respective tests.

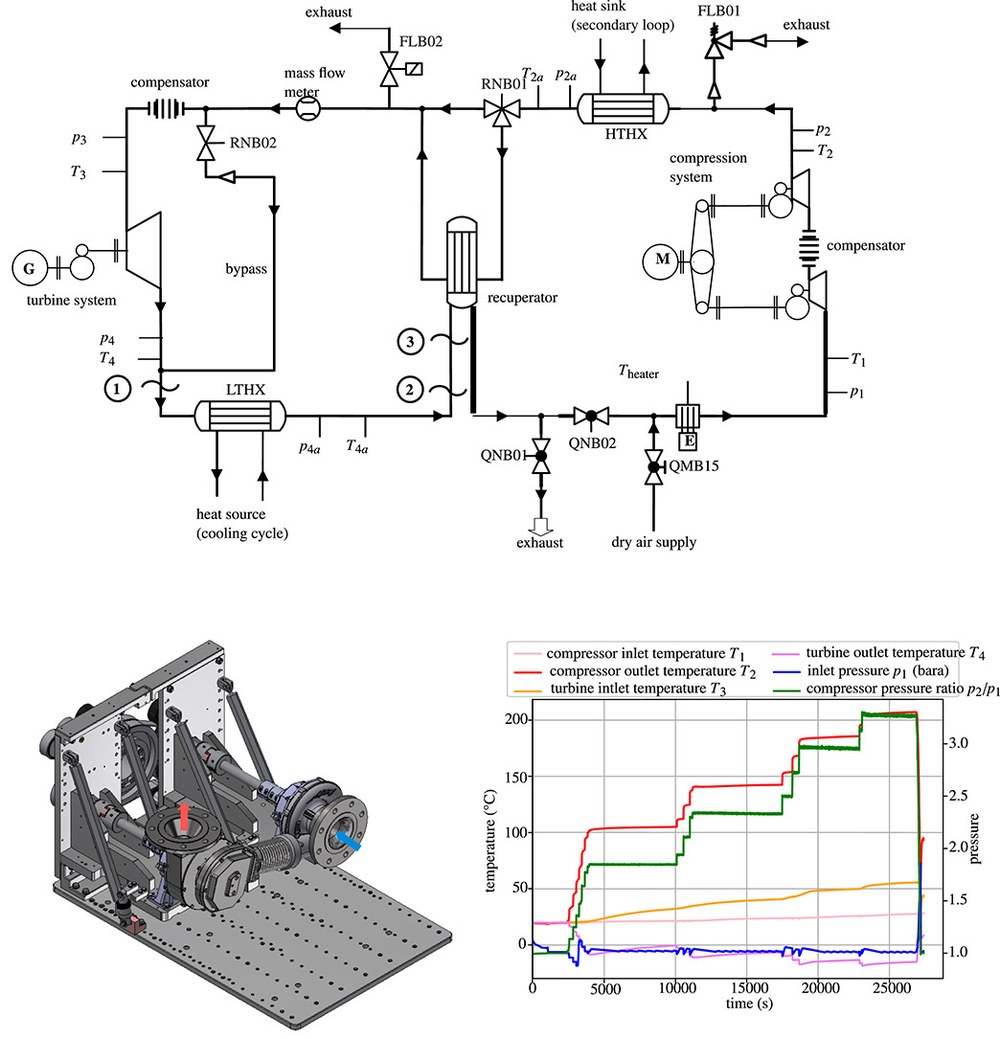

The Brayton process is a cyclic process that is primarily used in gas turbines for power generation or aircraft engines. If the cycle is run in the opposite direction, it is also suitable for heat pumps and chillers. For the heat pump, the process consists of compression, heat dissipation, expansion and heat supply. It is realised as shown in Figure 1. A compressor driven by an electric motor (M) compresses the air, causing it to heat up. The heat energy is transferred to the heat consumer (industrial process) in the downstream high-temperature heat exchanger. The air is expanded again by a turbine that drives a generator (G) for electrical energy recovery, whereby it cools down and releases energy to the turbine. Heat is then supplied from a source (waste heat, ambient air, hot water) via a further heat exchanger. This closes the cycle. A recuperator can be switched on and is used to recover the heat energy within the process.

Project aim:

The aim of the project is to demonstrate the feasibility for high process temperatures above 200 °C. In addition, the real operating behaviour is to be investigated, as there are numerous models and concept studies worldwide, but no comparable real demonstrator. The transient operation (start-up, shutdown and load changes) as well as the pressure and temperature losses of the real components are of particular interest.

Various components, temperature ranges and operating modes are to be tested in the system, which is why the CoBra is constantly being developed further. Further areas of research are the efficient control and regulation of the system in order to demonstrate that heat generation can follow real process requirements.

Initial commissioning in heat pump operation with a closed circuit took place in 2024. Two radial turbo compressors were used in series for these tests.

Current status of development:

2024/2025: Test series with two-stage turbocompressor, output up to 60 kW, process temperature up to 260 °C

2025: Test of a more powerful compressor (single-stage radial turbocompressor) as part of the DiskoHT project