DigiWP

The reduction of CO₂ emissions through decarbonization is an important instrument for climate protection. A large proportion of direct energy-related greenhouse gas emissions come from the use of fossil fuels to provide energy for industrial processes. Most of the energy required in industrial processes is in the form of process heat. Currently, process heat supply (>150 °C) is still mainly generated by burning natural gas or oil, which are the main sources of CO₂ emissions. The use of renewable energies is increasing, but does not play a major role at the moment. For the transition to a climate-neutral economy by 2050, heat demand must be met by zero- and low-carbon energy technologies.

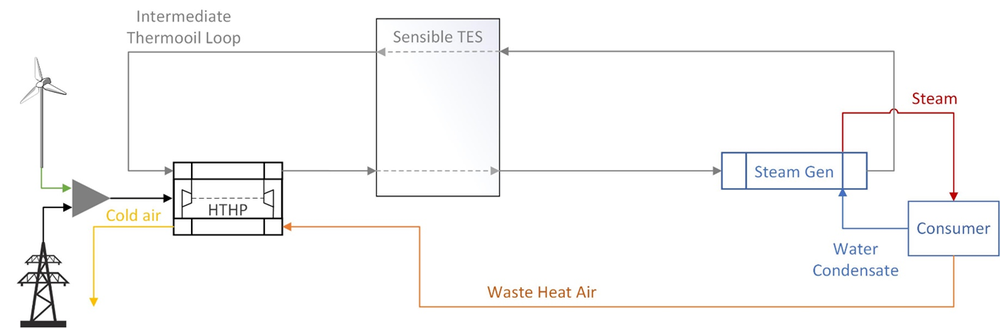

An essential key component in the heat transition are novel high-temperature heat pumps (HTHP) based on the closed Brayton and Rankine process (CoBra and ZiRa). These HTHPs will achieve a power-to-heat technology with significantly higher temperature levels than current systems that provide process heat in industrially relevant temperature ranges above 250 °C. In addition, the HTHPs are an important building block in energy storage concepts, enable grid balancing capability through partial load operation and thus form an attractive power-on-demand option. Integrated in an increasingly regenerative power supply system, the HTHP concepts can represent an innovative and climate-neutral concept for industrial heat supply.

The key question of the project DigiWP (AI-based mapping of a high-temperature heat pump for the decarbonization of industrial processes through efficient energy use and consideration of fluctuations in regenerative energy sources) is: How can the energy-efficient provision of low-CO₂ high-temperature process heat using HTHP, thermal energy storage (TES) and fluctuating renewable electricity look like?

The main goal of the overall project is therefore the decarbonization and flexibilization of process heat generation in industry through the efficient use of the HTHP concepts developed by DLR-DI. The project goals are:

- Identification of electrifiable industrial processes with broad application, whose process heat demand can potentially be met by using CoBra/ZiRa in order to investigate potentials in terms of CO2 reduction, energy efficiency and waste heat utilization

- Virtual integration of digital HTHP twins (CoBra/ZiRa) into industrial processes and coupling with other energy technology components

- Development of optimization and AI methods for energy-efficient provision of renewable process heat using cost- and/or emission-optimal predictive process control

- Evaluation of the developed multi-component systems for the considered industrial process