EMPHATICAL

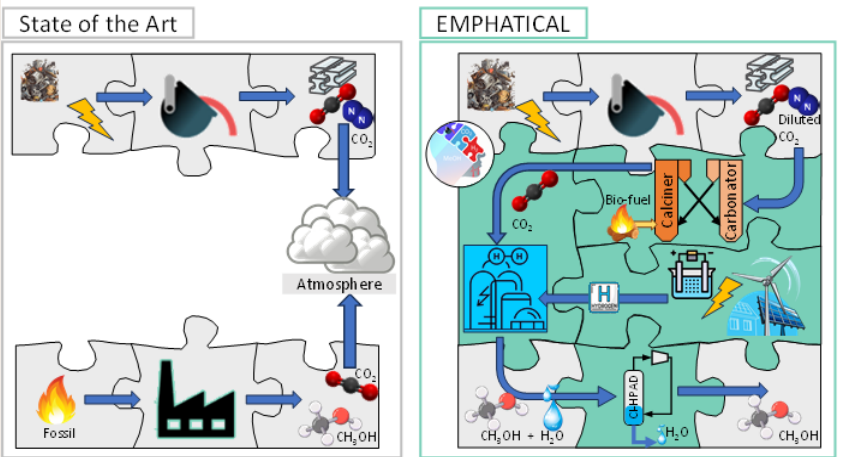

The EU-funded EMPHATICAL project (Efficient Methanol from Pumped Heat and Calcium Looping), launched in November 2024, will address the challenges the metallurgical industry faces in transitioning to zero-emission and circular carbon processes. This will be achieved by designing a Firstof-a-Kind (FOAK) demonstrator to establish the economic and environmental viability of the electrified metallurgical industry and methanol production. EMPHATICAL is developing a demonstrator plant (TRL 7) that will use innovative processesto capture gases containing residual CO/CO2 from highly electrified metallurgical industries using the energy-efficient integration of technologies to capture, purify, and convert CO2 to e-methanol, powered by green hydrogen.

To meet 2050 climate goals, the metallurgical industry must reduce its carbon dependence and address difficult-to-abate emissions. EMPHATICAL will provide a cost-effective, sustainable solution, integrating renewable energy and circular processes to transform CO2 into valuable products like methanol. This approach will help the industry transition to net-zero emissions and carbon circularity. “The EMPHATICAL consortium is committed to a more sustainable future for the metallurgical industry by turning industrial CO₂ emissions into valuable e-methanol using cutting-edge technologies,” says Yvonne van Delft, TNO, EMPHATICAL Project Coordinator. “By integrating renewable energy, circular processes, and innovative CO₂ capture, we are tackling some of the toughest challenges of the metallurgical industry. With demonstrator, we’re proving that the path to net-zero is not only possible but economical and scalable!”

EMPHATICAL will demonstrate its concept, advancing it from TRL 5 to TRL 7, with the goal of reducingspecific energy consumption and production costs by 25%. Risks are addressed early, with each unit able to operate independently, ensuring immediate performance and efficiency gains. The optimal process will be demonstrated by SWERIM at the Lulea test site using two types of residual gases: i) from secondary steel production in an Electric Arc Furnace (EAF), and ii) from submerged arc furnaces (SAF) in ferrochrome alloy production. The successful demonstration will lay the critical stepping stone for the construction of a FOAK plant within a timeframe of 4 years, targeting a reduction of 41 million tons of CO₂ annually by 2050. A comprehensive assessment of economic and environmental impacts will guide the project’s development and demonstrate its long-term viability.

Project facts

Duration | 01.10.2024- 30.09.2028 |

more information | EMPHATICaL – Pioneering a Zero-Emission Future for the Metallurgical Industry |