EEETHOS

Industrial process heating accounts for 16 % of total final energy demand and 13 % of the greenhouse gas emissions in the EU. Decarbonizing industrial process heating through electrification and increased energy efficiency is a key measure for reaching the climate targets in 2030, reducing the dependency on fossil fuels, strengthening the exploitation of local renewable energy sources and increasing the competitiveness of the European industry. While there are efficient technologies such as industrial heat pumps available for temperatures below 150 °C, there is a clear demand for novel technologies for processes with heat demands at higher temperatures.

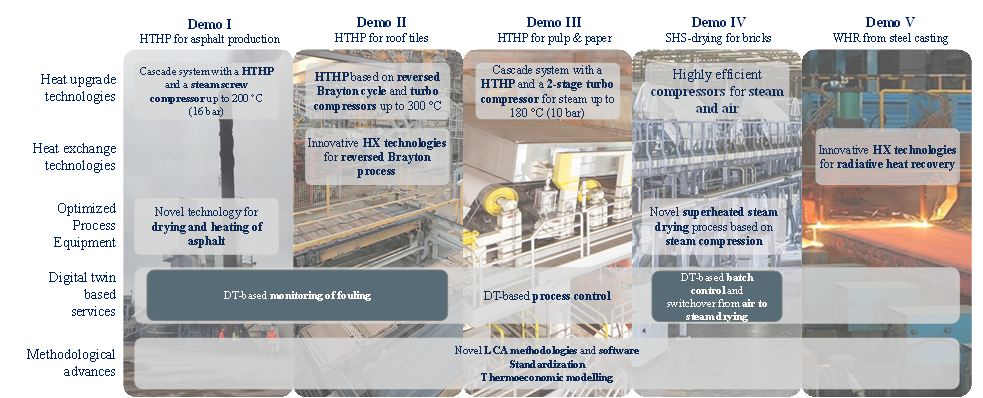

EEETHOS fills this gap by developing key-enabling technologies for energy efficient, flexible and decarbonized process heating, including two high-temperature heat pump solutions for steam supply at up to 200 °C, a reversed Brayton heat pump with supply temperatures up to 300 °C, an innovative technology for heat pump-based drying and heating of minerals, a highly integrated steam compression-based solution for superheated steam drying and a heat capturing device for radiative waste heat recovery, optimized by use of digital twin-based solutions. These key-enabling technologies will be demonstrated to TRL7 in five installations at industrial end-users representing EUs energy intensive process industries: asphalt, ceramics, pulp & paper, bricks and steel. These technologies are scalable for plant-wide implementation, allow a complete decarbonization at energy savings of 43-86 %, and can be based on local renewable energy sources. By developing and demonstrating key-enabling technologies at large scale EEETHOS will be a cornerstone for decarbonized, efficient and competitive European industry.

EEETHOS will develop and demonstrate breakthroughs in technology for optimisation of thermal energy flows to drive energy efficiency in five key energy-intensive European process industries: high temperature heat pumps (HTHPs) for asphalt, ceramic, and pulp and paper production, superheated steam drying for brick production and waste heat recovery for steel casting. The increases in efficiency and utilisation of recovered heat will decrease the need for high temperature installations, leading to lower investment costs. Rooted in five highly process-integrated industrial demonstrators, EEETHOS’ other solutions include system-agnostic developments in 2 digital twin-based modelling services, standardisation, LCA, and technoeconomic methodologies, decarbonisation strategies, and new business models. EEETHOS’ thus increases process flexibility across the industries of the P4P partnership, and our thorough exploitation plans will accelerate the European process industry’s progress towards Climate Neutrality goals, fossil fuel independence, and industrial resilience, decarbonisation, and competitiveness.