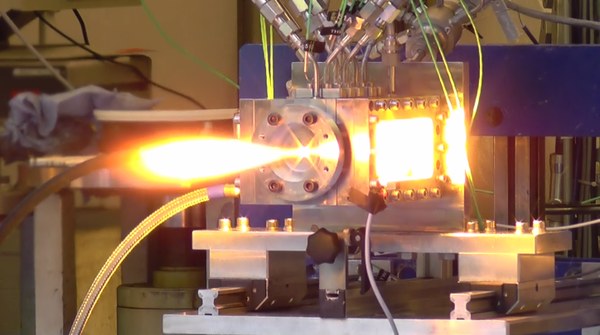

Test Bench Complex M11

Fuels | |

|---|---|

Monopropellants / catalytic propellants in research, development and qualification phases | Hydrogen peroxide, ADN-based propellants, nitromethane-based propellants, premixed fuel-oxidizer mixtures, water-based propellants, microencapsulated propellants, reactive pure substances, explosive substances and pyrotechnic compositions |

Bipropellants / hyperols in research and development phases |

|

Hybrid combinations in research and development phases | based on kerosene, HTPB, PE, ABS, glycidyl azide polymer (GAP) |