From the classroom to the test stand - An internship at RSC³

- Student Interns Visiting RSC³ for Two Weeks

- From the cleanroom to the engine test stand – we guide interns through our departments to showcase how the overall concept of Responsive Space is composed of our various segments.

- Hands-on experience instead of just theory: Interns use our research facilities for their own experiments.

Conveying the relevance and knowledge surrounding Responsive Space is a central part of our recurring student internships at RSC³ in Faßberg. From February 3rd to February 14th, 2025, we welcomed students from the surrounding area for an internship with us.

At RSC³, we have made it our mission to provide our young visitors with transparent and practice-oriented insights into our work and infrastructure, making a complex topic like Responsive Space accessible and tangible.

Through a structured internship plan, our interns gain detailed insights into each of our segments during their nearly two-week stay. They are accompanied by our qualified employees, who answer their questions regarding Responsive Space and provide practical demonstrations of how we use our state-of-the-art facilities to communicate with satellites in Earth orbit, cast and ignite propellants on our test stand, or test satellite components in load simulations to ensure they can withstand real-life stress during actual spaceflight.

Hands-on Experience in the RSTEC (Responsive Space Technology Evaluation Center)

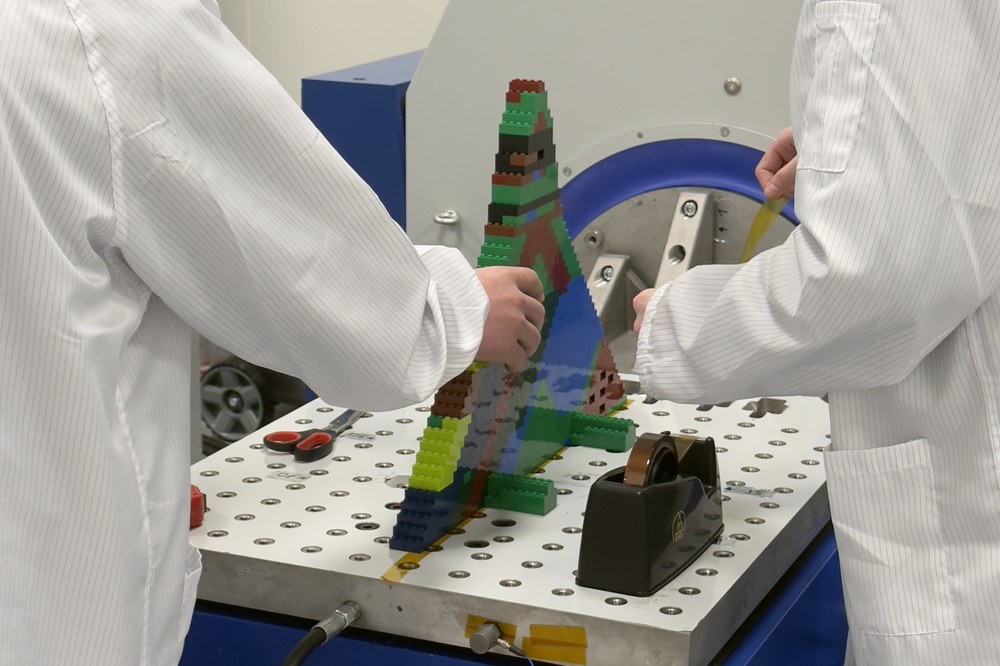

This is also where our interns conducted their own experiments: In our Responsive Space Technology Evaluation Center (RSTEC), our vibration test facility allows us to examine mechanical stress on primary structures, subsystems, and components under various load scenarios. In this context, our interns designed a LEGO model and independently constructed, measured, and mounted it onto the vibration test plate. Under the supervision of our employee Hannes Brandt, the stability and integrity of the LEGO model were put to the test on the vibration test plate. The test setup was ready, and the test began:

Initially, the vibration test system gradually increased the vibration load with an acceleration of 1G. As the oscillations reached about 25 Hz (equivalent to 25 vibration movements per second), they became so fast that they were no longer visible to the naked eye. The LEGO model appeared to stand still, yet the display screen showed an increasing curve that precisely illustrated how the vibration test plate moved the model with remarkable precision and speed.

At 1000 Hz, the maximum performance was finally reached – and contrary to expectations, the model was still standing. It was only at twice the acceleration (2G) and a frequency of just 2 Hz that the model gave in and broke apart. Nevertheless, during the dismantling of the experiment, our interns were fully convinced of their model’s success in the first test run.

Tour of the LaBoT (Laser Ground Station)

Another highlight was the tour of our Laser Ground Station (LaBoT) as part of the ground segment presentation. Led by our employee Maurice Uteg, our interns had the opportunity to explore the dome, the telescope, and the control container. The operation, as well as the demonstration of the telescope dome’s alignment and rotation via the control computer in the control container, provided an intuitive impression of how we use the telescope to track satellites in their orbits.

On the control container’s screen, parabolic curves appeared – sometimes long, sometimes very short. These curves allow us to determine the distance and speed of satellites within the telescope’s field of view.

In this context, we demonstrated what it takes to make a satellite visible using a reflecting telescope. At the same time, it is equally important to protect the highly sensitive technology from harmful environmental influences: Sensors and detectors on the system display weather forecasts, temperature, humidity, and wind speed on the control computer to ensure that environmental conditions allow for the safe operation of LaBoT.

RSC³

Theory combined with practice

Integrating practical experience into the theoretical introduction to our segments proved to be an exciting and valuable application experience throughout the internship, making complex relationships and topics more tangible. Whether building a water rocket in the launch segment, testing the LEGO model in the space segment, touring LaBoT, or receiving an introduction to the Python programming language in the ground segment – all these activities provided intuitive insights into how complex theoretical concepts can be understood through simple practical applications.

In a final challenge, our interns had to apply the knowledge they had acquired by participating in an escape game, embarking on a scavenger hunt to find “Responsy,” our site’s mascot. Their farewell was rounded off with a positive feedback discussion.