Virtual acoustic twin of distributed propulsion

The VIRLWINT project will carry out a psychoacoustic evaluation of distributed propulsion systems based on auralisation data.

The future of aircraft with distributed propulsion will largely depend on how their engine noise is perceived by people. Particularly in urban areas, public acceptance may depend on how loud or annoying their propulsion systems are perceived. Therefore, at the Institute of Propulsion Technology, we are investigating aerodynamic noise sources and their acoustic effects to enable low-noise engine designs and facilitate the integration of these aircraft into urban airspace.

Current research shows that, in addition to safety, the noise generated by increased air traffic poses a major challenge. Engine noise is a significant contributor to the overall noise emissions of an aircraft. Furthermore, the perception and annoyance of noise from distributed propulsion systems differ from those of conventional aircraft and depend more strongly on psychoacoustic factors, such as the perception of fluctuations and sharpness. As a result, propulsion noise and its subjective perception are key factors for the success of Urban Air Mobility (UAM) aircraft and their acceptance by society. At the Institute of Propulsion Technology, we are therefore investigating acoustic effects and noise reduction techniques that enable the development of low-noise propulsion systems.

Fan stages are typically designed with more stator than rotor blades. A choice primarily driven by acoustics, as the rotor-stator blade ratio significantly influences noise generation. A higher number of stator blades relative to the rotor can reduce tonal noise by design. Conversely, designing fan stages with fewer stator than rotor blades offers advantages such as lower manufacturing and maintenance costs as well as reduced broadband noise. However, these configurations tend to generate more tonal noise, which is typically perceived as unpleasant and annoying. If this tonal noise can be mitigated, fan stages with fewer stator than rotor blades could become a promising propulsion option for UAM aircraft.

In the DLR research project VIRLWINT (Virtual Acoustic Twin of Distributed Propulsion), we are investigating acoustic effects to minimize tonal noise in fan stages with fewer stator than rotor blades. Our research study demonstrates that for low-speed fans engines, such as those used in urban air mobility, two key mechanisms can contribute to tonal noise reduction. Firstly, a tonal noise reduction occurs when the propagation angle of the excited acoustic modes is aligned with the stator leading edge angle. This can be achieved by carefully selecting the number of rotor and stator blades. We have developed and validated a design rule to ensure that this effect can be transferred to other fan stages. Secondly, for low-speed fan engines, specific rotor–stator blade count combinations exist, for which a cut-off condition can be achieved for the blade passing frequency tone despite the stator vane count being lower than the rotor blade count. This is called an inverse cut-off, which exclusively occurs for low-speed fans, as the effect depends on the rotor tip Mach number. To ensure that this effect can also be transferred to other low-speed fans, we derived a design rule to estimate the limiting rotor tip Mach number.

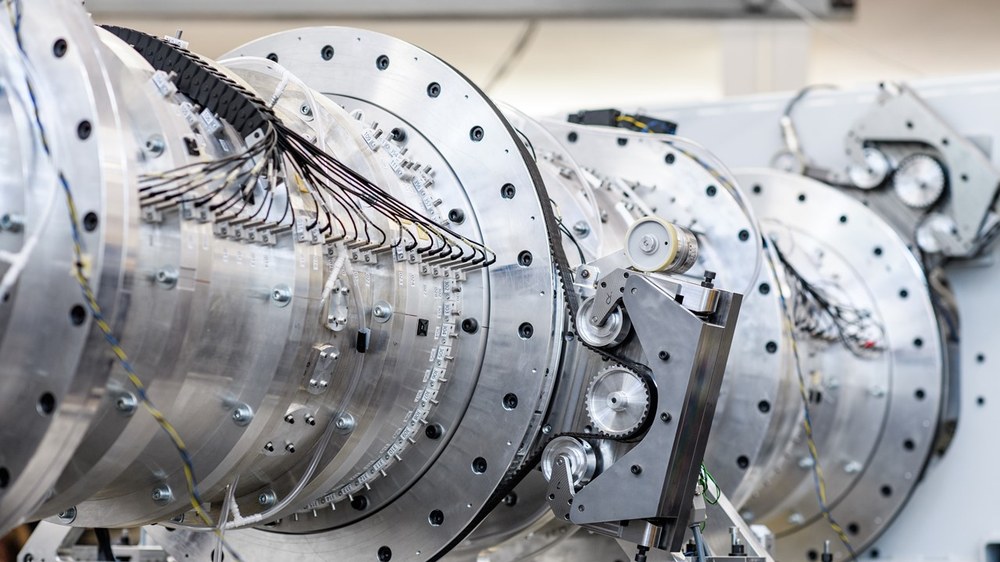

In the VIRLWINT project, we demonstrate the application of both effects on two low-speed fan stages with fewer stator than rotor blades. In collaboration with DLR Systemhaus Technik, we have manufactured the new components: a blisk rotor with 31 blades and a stator with 10 blades. At the Institute of Propulsion Technology, the Department of Engine Acoustics experimentally investigates such fan stages under representative operating conditions for urban air mobility applications in the CRAFT test facility A recent milestone in our research was the successful integration of the new components into the test rig, followed by the first successful test run of the initial fan stage.

To capture the sound fields in the duct as comprehensively as possible, 169 microphones are mounted upstream and downstream of the fan, with their diaphragms flush with the duct wall. This ensures that the microphones do not interfere with the aerodynamic flow. The microphones are arranged in a ring at both the inlet and outlet, enabling a detailed analysis of the engine noise components in the form of acoustic modes. To determine the tonal modes, additional microphones are positioned in a line within a rotatable duct section. This setup allows for a step-by-step scanning of the sound field at 1,770 positions in the inlet and 1,298 positions in the outlet. To simulate different installation scenarios various fences and perforated plates can be mounted at the test bench inlet. This setup enables the simulation of fuselage-embedded engines, distributed propulsion systems on the wings, or an undisturbed flow. To deepen our understanding of sound sources and their relationship to flow conditions, we also record velocity profiles and turbulence distributions in the duct using hot-wire anemometry and total pressure rakes, in addition to the acoustic measurements.

Our aim is to use the measured data to evaluate the noise levels of distributed propulsion systems and their psychoacoustic effects. Therefore, an UAM concept aircraft powered by 26 ducted fan engines is developed within the VIRLWINT research project. Each fan has a diameter of 46 cm and is represented by measurement data obtained from the CRAFT test bench. Three fan designs are available for measurements on the CRAFT test rig: a reference fan (baseline) and two new fan stages with fewer stator than rotor blades, referred to as low-broadband and low-tone designs.

To ensure comparability, these fan stages have been optimized to maintain nearly identical aerodynamic characteristics, including efficiency, pressure ratio, and resulting thrust.

By implementing tonal noise reduction mechanisms, it was possible to create fan designs with diverse acoustic noise signatures. The following figure illustrates the impact of fan design on the tonal noise radiation of the distributed propulsion system consisting of 26 fans. The noise directivities are plotted on hemispheres with radius 100 m. The propulsion system equipped with the baseline fan emits tonal noise predominantly backwards relative to the direction of flight. In contrast, the low-broadband design has been deliberately engineered so that the tonal sound is primarily emitted forwards. For an observer on the ground, this means that in the first case, the tones are heard mainly after the aircraft has passed, whereas in the second case, they are heard before the aircraft arrives.

For the low-tone fan design, both tonal noise reduction mechanisms described above were combined in a single fan stage. As a result, tonal noise excitation was significantly reduced. In terms of noise perception, this leads to a more hissing and rushing sound instead of a tone-dominated sound.

The effect and acceptance of these different noise characteristics on people on the ground will be evaluated in future listening studies with test participants. For this purpose, the audio files with realistic sounds are required. To achieve this, the fan noises measured at the CRAFT test rig are processed in two steps. In the first step, a virtual flyover of the aircraft is simulated, calculating the noise propagation through the atmosphere to the human ear in the form of a spectrogram. In the second step, this spectrogram is auralized, which means that it is converted into an audio file. The test persons can then listen to the audio files in a test room via headphones. The participants will then be asked to evaluate their subjective noise perception. The listening tests are planned for next year at the DLR Institute of Aerospace Medicine in Cologne.