In addition to the Institute of Propulsion Technology, five other DLR institutes are working with industrial partner MTU Aero Engines on the further development of this concept.

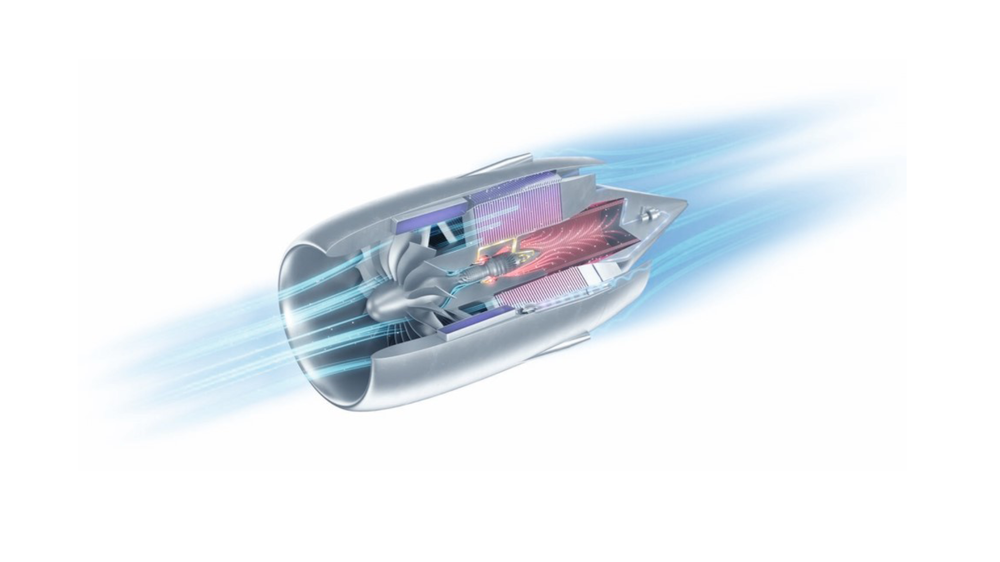

The highlight: The Water-Enhanced Turbofan (WET) uses the residual heat from the engine's exhaust to increase the engine's efficiency. The WET concept combines the Joule-Brayton process with a parallel Clausius-Rankine cycle (Cheng cycle). Superheated water vapour is injected into the combustion chamber to participate in both combustion and power generation in the turbines. The liquid water is recovered from the exhaust gas upstream of the thrust nozzle, pumped to high pressure and then evaporated in a heat exchanger using the residual heat from the exhaust gas jet and returned to the combustion chamber. The result is a closed water cycle. Overall, the thermal efficiency of the propulsion system is improved and the power density of the core engine is increased, allowing higher by-pass ratios for the same fan diameter.

MTU Aero Engines

Reduced fuel consumption and fewer climate-damaging emissions

Initial studies indicate a significant potential reduction in mission fuel consumption compared to the next generation of geared turbofans. In addition to carbon dioxide savings, the climate impact of non-CO2 effects should also be reduced by reducing nitrogen oxide emissions and condensation trails.

DLR's Institute of Propulsion has several activities:

Total system thermodynamic evaluation: Scientists develop an overall thermodynamic model to simulate the interaction of individual components and determine an optimal thermodynamic cycle. The results of detailed investigations of individual components will be integrated into the overall system model and the simulated operating behaviour will be included in the climate assessment. In addition to paraffin operation, the use of hydrogen as an energy source will be evaluated and synergy effects sought.

Simulation of the evaporator: The evaporator for heat recovery is a key component of the WET concept and a first for the aerospace industry. Compared to stationary applications, aerospace applications have completely different requirements in terms of space, weight and integration into the overall system. To meet these requirements and to evaluate different designs, the researchers are evaluating compact heat exchangers using a clever combination of correlation-based preliminary design methods and CFD.

Experimental study of the vaporiser: A similarity experiment for an aerospace vaporiser is being designed and built at the Institute of Propulsion Technology. The experimental investigations will be used to validate and calibrate design methods and simulations. In addition, the feasibility of evaporator concepts will be investigated and important foundations for further technology development will be laid.

The work will be carried out in close cooperation with the partners and other DLR institutes. The DLR Institute of Combustion Technology will gradually develop a demonstrator for the WET concept based on a retrofitted helicopter engine. Researchers at the DLR Institute of Atmospheric Physics will calculate the overall climate impact of a future aircraft with WET technology and assess the potential savings compared to conventional aircraft gas turbines. The DLR Institute of Air Transport is developing a 3D emissions register to map the use of WET engines at fleet level. The DLR Institute of Materials Research is analysing, among other things, the service life of the materials. At the same time, the DLR Institute of Vehicle Concepts is analysing the advantages of a combination with a free-piston composite cycle engine concept (CCE).

Running Time

2023 - 2026

Keywords

Gasturbine, Sustainable Aviation Fuels, hydrogen

BMWK