E-Fryer

Potato chips are known to most as a tasteful, yet highly caloric snack. What most people don't know, is that the production of potato chips is also energy intense. The water from the potatoes has to be nearly completely evaporated during the frying process, with the heat coming from fossil fuel boilers. For the 1.9 million tons of potato chips that were produced in Europe in 2020, a total of 4.37 Mt CO2 were released into the atmosphere.

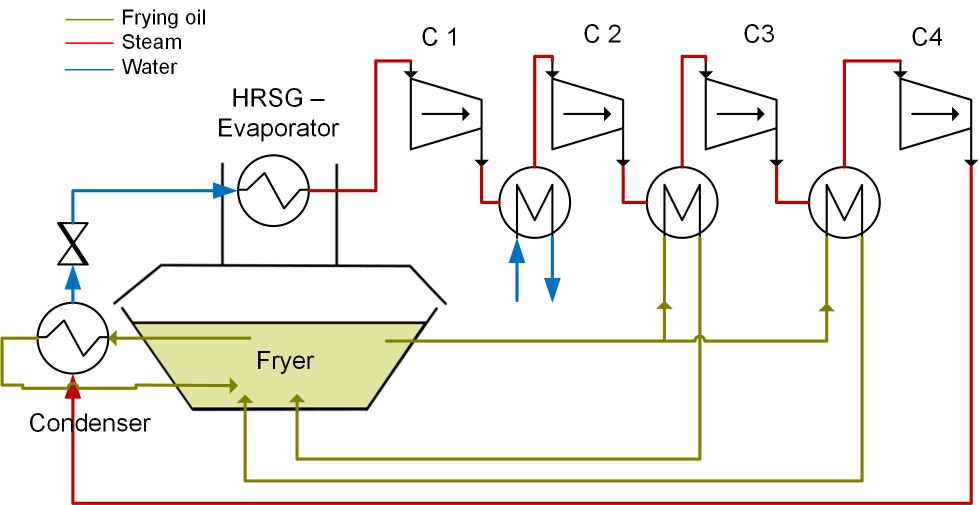

In an effort to cut those emissions, the snacks manufacturer Lorenz-Bahlsen teamed up with the fryer manufacturer Rosenqvists, the turbo-machinery supplier TTI and the DLR Institute of Low Carbon Industrial processes in a project under the CET-Partnership framework. Over the next years, the project partners will install and test a heat recovery steam generator in the stack of a chips fryer in the plant of Lorenz in Stanowice in Poland. This heat exchanger will allow to produce low-pressure steam from the exhaust of the fryer. Simultaneously, TTI and DLR will develop steam compressors that will be qualified in a test bench set-up. With these two proof-of-principle test campaigns a virtual design for a complete high temperature heat pump that upgrades the heat to temperatures necessary for the frying process will be developed, allowing to demonstrate the economics of the approach.

This projects differs from other in that it aims a deep integration of a heat pump into the process, which generally achieves higher efficiencies compared to utility scale solution while also offering the opportunity for modularization. The latter ensures the scalability of the developed product.