VP 2.0 compressor test rig

Compressor test rig VP 2.0 - Development and testing of industrial steam compressors

The decarbonisation of industrial process heat is one of the key challenges of the energy transition. In many industrial sectors - such as the paper, food and chemical industries - a considerable amount of energy is required in the form of process heat in the temperature range of 100 to 500 °C. This heat is still predominantly provided in the form of steam. To date, this heat has mainly been provided by burning fossil fuels. New technological solutions are required to operate industrial processes in a climate-friendly, efficient and economical way in the long term.

One promising approach is the use of high-temperature heat pumps (HTHP), which can raise unused waste heat to a higher temperature level and thus replace fossil fuels in the process heat supply. The Institute of Low Carbon Industrial Processes develops and operates its own HTHP demonstration plants for this purpose - the ZiRa and CoBra plants, which are used to test new system and operating concepts under real conditions. However, a key prerequisite for efficient HTHP HTHP is the availability of suitable turboradial steam compressors - this is where the VP 2.0 compressor test rig comes in.

Steam compressors as a key technology for high-temperature heat pumps

In many industrial applications, waste heat is generated at temperatures between around 40 and 70 °C, while at the same time centralised steam networks are operated at pressures of 6 to 16 bar. Commercial heat pumps can already generate usable process steam from this waste heat, but typically only at comparatively low pressures and temperatures. In order to be able to feed this steam into existing steam networks or use it again in the process, powerful steam compressors are required to significantly increase the pressure and temperature.

Especially in the industrially relevant output range of around 0.1 to 1 MW, there has been a lack of commercially available compressor solutions that reliably cover operation with water steam at high temperatures and pressures. While large manufacturers are focussing primarily on very large systems for the district heating market, there is a technological gap for industrial applications. At the same time, there are hardly any realistic test environments available to systematically develop, test and optimise such compressors.

The VP 2.0 compressor test rig

The new VP 2.0 compressor test rig is being built at our Institute in Zittau with the aim of establishing a high-performance, application-oriented test infrastructure for the development and testing of industrial turbocompressors. The VP 2.0 compressor test rig reproduces operating conditions at a technological maturity level of around 5 and enables tests in the industrially relevant performance range.

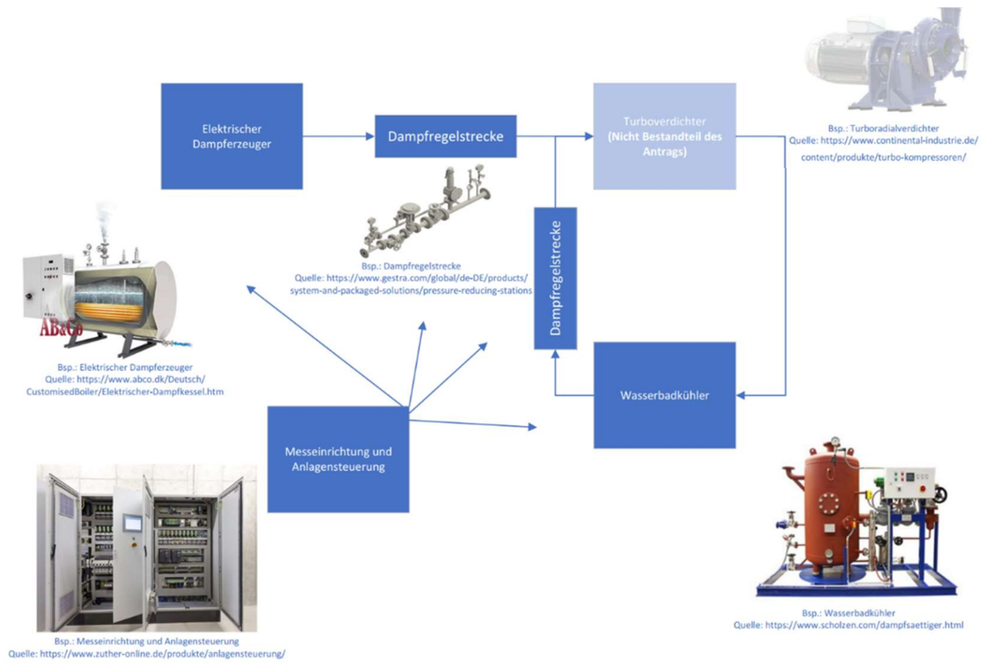

The VP 2.0 is designed as a closed steam circuit (schematic diagram of the set-up in Figure 1), in which water steam circulates as the working medium. The pressure and temperature of the steam is adjusted upstream of the compressor via a steam control system, compressed in the steam compressor to be tested and then cooled and expanded again. This allows stable and reproducible operating conditions to be realised, enabling continuous testing of different compressor concepts. A powerful measurement and control system monitors operation and records all relevant process variables.

The compressor test rig has a modular design and can be configured flexibly. It allows tests of complete compressor units as well as the targeted investigation of individual subsystems, such as bearing and sealing concepts, rotordynamic behaviour or control strategies. Typical operating parameters include mass flows up to around 1 kg/s, electrical drive powers up to 200 kW and outlet temperatures and pressures relevant to industrial high-temperature heat pumps and process steam applications - approx. 350 °C and up to 30 bar.

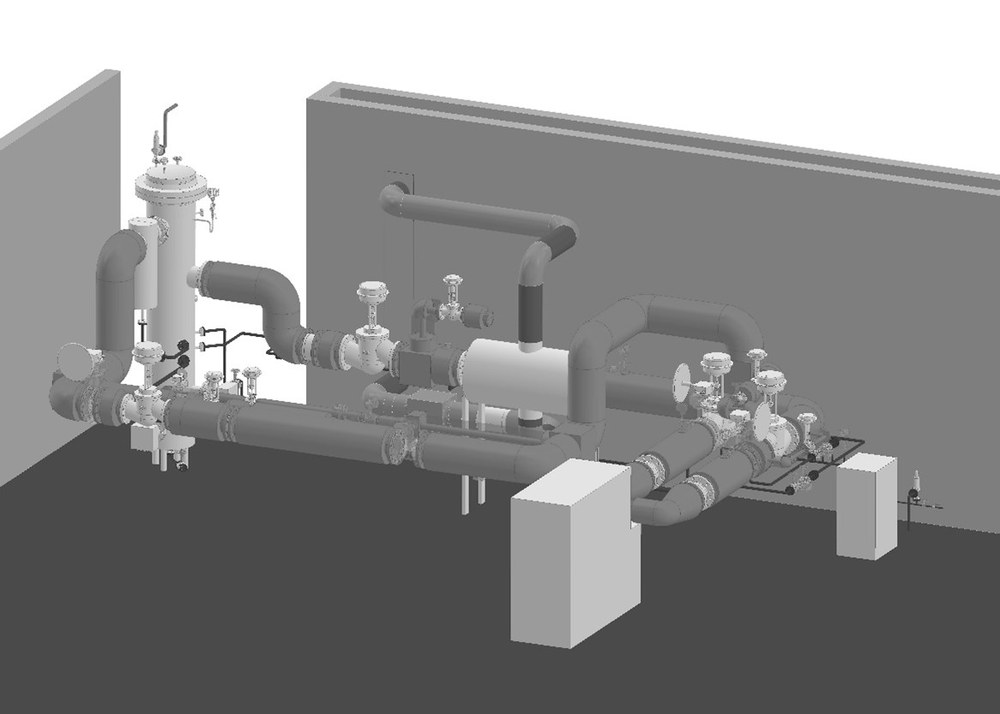

Figure 2 shows the VP 2.0 compressor test rig as a 3D model.

Research, development and application

The VP 2.0 compressor test rig provides the basis for interdisciplinary research and development work on industrial steam compressors. Expertise in fluid mechanics, thermodynamics, design, electrical engineering and measurement and control technology is incorporated into the design, optimisation and testing of the systems. Tests under realistic conditions can significantly increase the technological maturity of new compressor concepts.

A particular focus is on linking compressor development with the system development of high-temperature heat pumps. The experimental findings obtained at VP 2.0 are channelled directly into the further development of HTHP demonstration systems. This means that compressors can not only be examined in isolation, but also specifically investigated and optimised in conjunction with real heat pump systems.

The compressor test rig also serves as a platform for collaboration with industrial partners. It enables the joint development and testing of application-orientated compressor solutions through to functional demonstrations and supports the transfer of research results into industrial applications.

The DLR Institute of Low Carbon Industrial Processes

With the Institute of Low Carbon Industrial Processes, DLR conducts application-oriented research into industrial heat supply. A central focus is on the development, construction and operation of high-temperature heat pumps for industrial applications, including at the institute's own demonstration plants ZiRa and CoBra.

With the VP 2.0 compressor test rig, the institute is specifically expanding its research infrastructure to include the field of industrial vapour steam compressor technology. The construction, operation and scientific utilisation of the compressor test stand are the full responsibility of the institute. The experimental findings obtained on the VP 2.0 are channelled directly into the further development of high-temperature heat pumps and into application-oriented research and development work.

Note on funding

The construction of the VP 2.0 compressor test rig is funded as part of the JTF RL Forschung InfraProNet 2021-2027 funding programme

Duration of the project: | 04/2025 - 02/2027 |

Total expenditure/costs of the project: | EUR 623,000.00 |

Funding reference: | 100749348 |