Virtualization, Predictive Simulations, Data Management for Digital Integrated Materials and Processes

Materials science is undergoing a major transformation toward a data-centric discipline. Modern AI methods are unlocking vast databases of material properties in ways that significantly expand the design and application spaces for new material solutions. Alongside advances in machine learning—such as large language models—this digital shift relies on the availability of machine-readable data that adheres to FAIR principles: Findable, Accessible, Interoperable, and Reusable—ultimately ensuring data is “AI-ready.” This enables autonomous, AI-driven discovery of materials in fully automated laboratories.

AI-based predictions of material performance are only as reliable as the data behind them. Therefore, gathering high-quality, precise experimental data is essential—whether under microgravity conditions for model development and simulation refinement, or through AI-powered high-throughput experiments in the lab. Integrating these data into material simulation workflows and validating them experimentally is a core methodological focus of the institute.

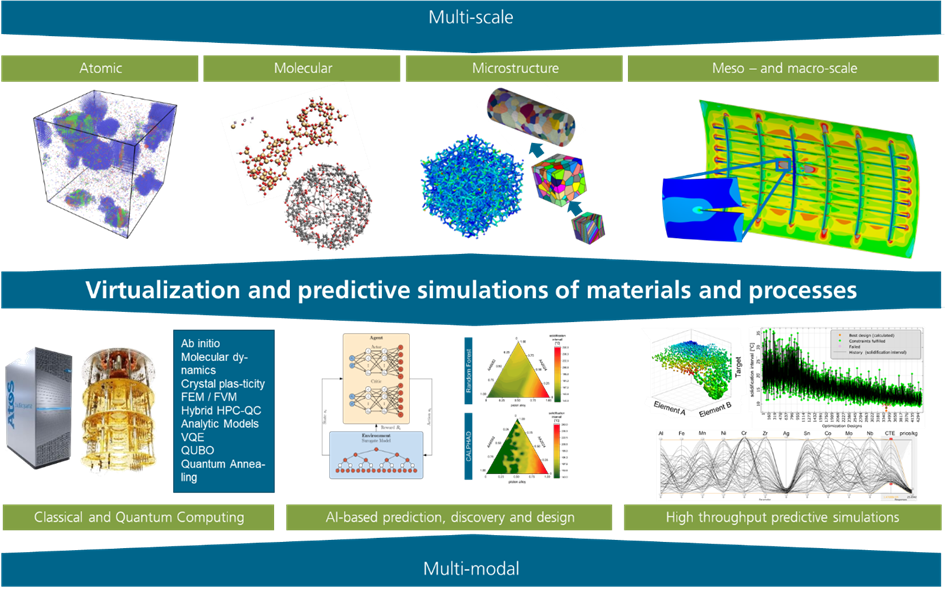

Another challenge lies in the complexity of today’s advanced materials, which may contain over 10 chemical elements selected from a pool of 50–60 commonly used elements. This leads to more than 10¹⁰ possible combinations, far beyond the capacity of classical computing, even with high-performance systems. In this context, quantum computing is emerging as a key technology for future materials design, enabling simulations that are inaccessible with current approximation methods. This extended view of materials science lays the foundation for data-driven optimization beyond traditional approaches.

Our institute leads two major projects within DLR’s QCI Initiative—QuantiCoM and QCMineral—focused on quantum-based simulation and optimization of materials using hybrid quantum computing and HPC approaches. These initiatives form a key differentiator for the institute and pave the way for advanced research in predictive simulations of materials and processes.

Importantly, we shift the focus from isolated material properties to complete process understanding. Modern materials-intensive applications and manufacturing methods demand insight into how processes affect material behavior in real-world use. Instead of the conventional bottom-up approach, we pursue a system-level perspective: starting from application requirements, using simulations to trace back to microscopic fundamentals. Our goal is to create virtual representations of entire process chains—across scales and methods—anchored in the institute’s D4 approach (Discover, Develop, Demonstrate, Deploy), as illustrated in the next Figure.