Supply Facilities

In order to be able to supply the various test benches with sufficient media and fuels, there are various tank farms on the site. Not only does the fuel for the engine supply need to be stored, but also media required for pressurizing the test bench or flushing the supply lines.

Tank farm for liquid hydrogen

The liquid hydrogen storage facility consists of a vacuum-insulated main tank with an internal volume of 270 cubic meters and a vacuum-insulated pilot tank with an internal volume of 50 cubic meters, in which the hydrogen is stored at minus 253 degrees Celsius. The tank farm has two refueling positions. Transfer lines are used to fill the P4.1 and P5 test benches directly with liquid hydrogen.

Tank farm for liquid oxygen

The liquid oxygen storage facility has a similar structure to the liquid hydrogen storage facility. In a vacuum-insulated main tank, 200 cubic meters of liquid oxygen are stored at minus 183 degrees Celsius. Oxygen is delivered by tanker vehicles with a volume of 15 cubic meters per vehicle. The stored oxygen is conveyed to the P5 test bench's travel tank via a 250 meter long transfer line.

For a test of the main stage engine of the Ariane launcher, 15 tankers with 40,000 liters of liquid hydrogen each and 8 tankers with 25,000 liters of liquid oxygen each are required.

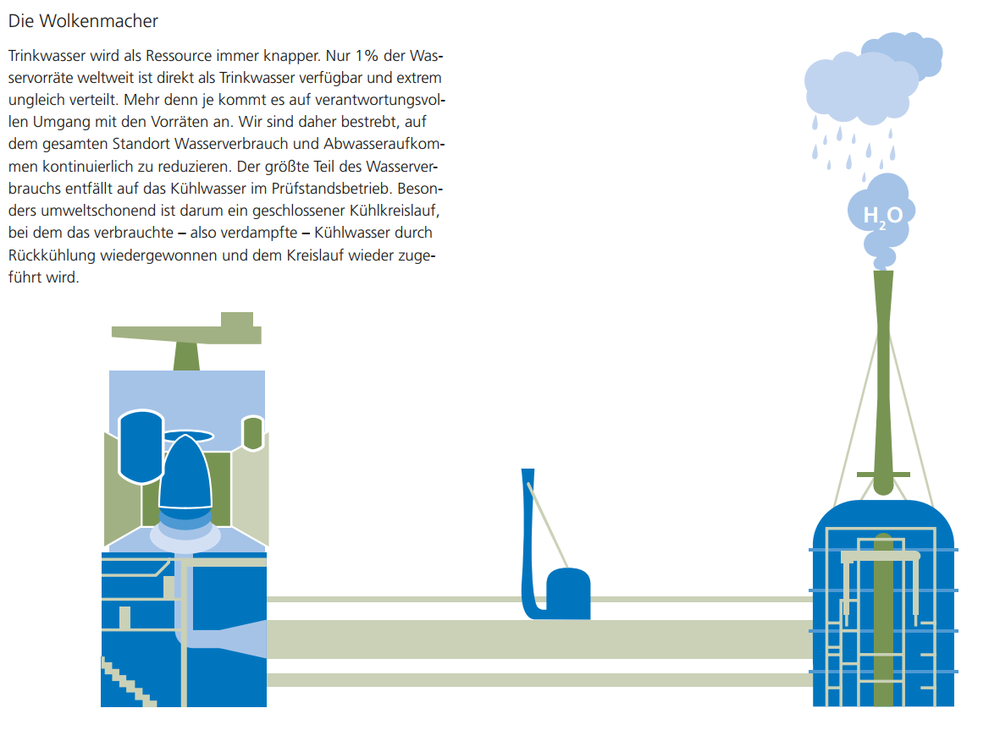

Cooling water for test bench systems

Drinking water is becoming an increasingly scarce resource. Only 1% of the world's water resources are directly available as drinking water and are distributed extremely unevenly. It is more important than ever to use these resources responsibly. We are therefore striving to continuously reduce water consumption and waste water volumes across the entire site. Most of the water consumption is accounted for by cooling water in test bench operation. A closed cooling circulation is therefore particularly environmentally friendly, in which the used – i.e. evaporated – cooling water is recovered by recooling and fed back into the circulation. The test benches are supplied with cooling water via elevated tanks with a total volume of 6,000 cubic meters.

Cooling water circulation on test bench P4.1

The tests for the Vinci upper stage engine take place in a vacuum, i.e. in a closed system. The evaporated water can be recooled in the condenser and fed back into the cooling water circulation after reprocessing. Six million liters of water are required for a test on the P4.1, which corresponds to 50,000 filled bathtubs. Of this, 95% is fed back into the cooling circulation; only 5% evaporates during the test in the form of pure water vapor.

Wastewater treatment

DLR operates a neutralization plant at the Lampoldshausen site to filter and purify wastewater from test bench operations. The site has developed a wastewater disposal concept for separating, treating and disposing of this wastewater, which has different levels of contamination. An average of 6,000 cubic meters of industrial wastewater is produced annually during the operation of the test benches. That is roughly the amount produced by 50 households per year. Where engines with self-igniting fuels are tested, sensitive waste water is produced – it must not be discharged into the sewer system without further ado. In DLR Lampoldshausen's own neutralization plant, pollutants are broken down that cannot be removed in a conventional sewage treatment plant. These pollutants, such as ammonia, nitrite, alcohols or hydrazines (storable fuels for satellites), are broken down during the neutralization process with the help of UV radiation or decomposed by other substances. All waste water is strictly controlled and evaluated before it is discharged into the environment.

Wastewater treatment through solar power

Using the solar wastewater treatment plant (SOWARLA) – a system developed by DLR together with industrial partners – some of the wastewater at DLR Lampoldshausen can also be purified using sunlight. The water is pumped through special glass tubes until the pollutants are broken down with the help of solar energy and photocatalysts. With SOWARLA, over 13,500 liters of water per day can be treated so that it can then be discharged into the environment or reused on site.