Technical Center M3

The three test positions enable a high number of tests per test day, with many different configurations. Due to the high test frequency and the possible adjustments, rocket combustion chamber technologies can be improved very quickly and efficiently at the M3. This leads to a rapid increase in the level of technological maturity of the technologies under investigation. In addition, new technologies can be developed and researched for use in engines.

Current areas of technology being researched at the M3 technical center are:

- Fuel coniditioning

- transient, two-phase flow

- injection

- Ignition and its sequencing

- combustion dynamics

The operating conditions correspond to those of:

- orbital propulsion systems

- for ignition processes of launch vehicle propulsion systems

Research with miniature combustion chambers

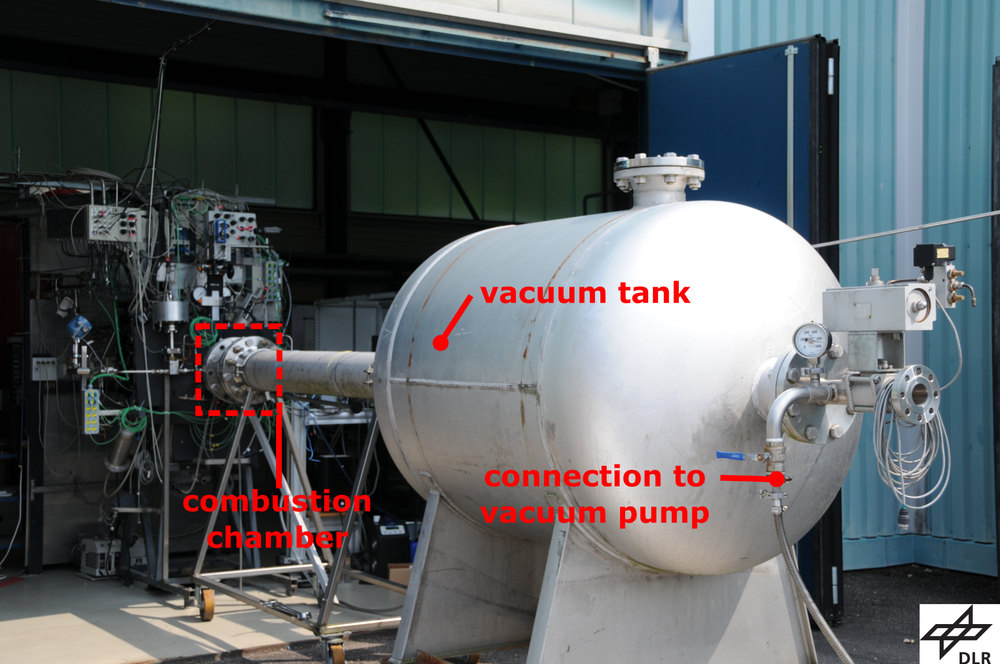

The M3.1 test bench focuses on investigating the transient processes involved in injecting cryogenic propellants into the combustion chamber, ignition and combustion of the propellant mixture. The aim is to carry out characterizations of new injection elements, basic investigations into the thermal load capacity of new materials for the construction of combustion chambers, or to investigate new ignition methods such as laser ignition. Gaseous and liquid oxygen (LOX) and gaseous fuels hydrogen (H2) and methane (CH4) are available for this purpose. A tank system can be used to carry out the ignition and combustion dynamics for low combustion chamber pressures before fuel injection up to approx. 50 millibars as well as at overpressures. This makes it possible to simulate start-up transients for rocket combustion chambers that are representative of ground conditions ("launch pad"), in space and in loading configurations ("retro-propulsion"). The M3.1 test stand is characterized by its high modularity and flexibility.

In particular, the following focal points of the combustion dynamics research group are being investigated:

- Fuel injection, in particular of coaxial, swirl and porous injectors

- Ignition sequencing

- Established and innovative ignition methods such as laser ignition

- Flame anchoring and stability

- Flammability studies

- material compatibility.

A number of optically accessible combustion chambers are available at the M3 technical center, which, in combination with the expertise of the Diagnostics & Support research group and modern high-speed cameras, allow a detailed insight into the combustion chamber processes.

Research into the optimal injection of rocket propellants

DLR research teams are investigating transient two-phase flows on the two test benches M3.3 and M3.5. These are of great importance in the flow of cryogenic propellants through the engine components (valves, injection heads, turbopumps) and in the injection of the propellants into the combustion chamber. The latter can take place in a vacuum if, for example, the combustion chamber of an upper stage engine is to be ignited in space. Here too, the M3 technical centre is characterized by its high modularity and flexibility, so that there are practically no limits to the configurations that can be investigated.

Technology testing and technology transfer

The following activities, among others, are carried out at the M3 technical centre as part of technology testing and technology transfer:

- Component tests for turbopumps

- Characterization of injector elements

- Ignition transients with different background pressures

- Nozzle flow and hot gas interaction with structural components (e.g. landing legs and heat shields)

- Component tests for turbopumps

- Characterization of injector elements

- Ignition transients with different background pressures

- Nozzle flow and hot gas interaction with structural components (e.g. landing legs and heat shields)