Automatica 2012

Again this year, the Robotics and Mechatronics Center (RMC) will be exhibiting at Automatica. Brand new research results and developments from automation and robotics, technological trends and the robotic systems of tomorrow can be experienced by professional visitors to the RMC booth. The RMC will be supported by its spin-offs, which impressively underscore the technology transfer successes not only for the medium-sized sector.

The following exhibits will be presented at the Automatica on the grounds of the Neue Messe Munich in Hall B3/Stand 520 between May 22 and 25, 2012, daily from 9 am to 5 pm.

- Sensor designs for surgical robotics

- Humanoid walking machine

- Human-centered Robotics

- Hand arm system

- Agile Justin

- Tele-present maintenance and repairs

- Multifunctional cell by the ZLP

- DEXHAND – space-qualified multi-finger hand

- Rigid force-torque sensor – FTS-100

- Multi-sensor navigation system IPS

- Brain-controlled robotics

- DLR-HIT five-finger hand

- RoboDrive high-performance servomotors

- Aerospace technology for industry

- DUALIS MedTech

Sensor designs for surgical robotics

One chief goal of surgical robotics is improving surgeons’ immersion through haptic and visual feedback. The required information is recorded and processed by means of sensors integrated in the instruments. While strain gauge strips and fiber-optic sensors are used to ascertain the forces and torques, Doppler ultrasonography sensors are used to palpate the vessels lying within tissues. The feedback to the surgeon can be displayed both visually, for example in the form of rigidity maps or force arrows, or by touch via the repellable input device. Handheld 6D input devices with optically registered motion are an alternative to mechanical input devices. By combining optical and initial measured data, any 6D motions used to control the system are recorded in real time. For complicated surgeries, for example minimally invasive operations on beating hearts, motion compensation by the surgical system is necessary.

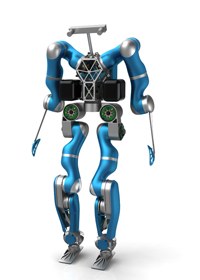

Humanoid walking machine

The DLR’s two-legged robot was further developed as a research platform for Humanoid Robotics and is being presented to the public for the first time at the AUTOMATICA. The developments in whole body torque control are presented on the system by means of walking motions, whole body motions and multi-contact situations.

Human-centered Robotics

The latest research results in physical human-robot interaction show that humans and robots can actively and safely share a workplace.

The central aspects of this are safety and intuitive interaction.

In order to make communications between humans and robots smooth and operating the system user-friendly, self-explanatory communication and interaction structures are created.

The developments aim both at industrial scenarios between humans and co-workers and service scenarios in hospitals in which medical staff and robots interact in everyday tasks. At the AUTOMATICA, the DLR is unveiling its latest prototype, which demonstrates these new approaches in an exemplary way. The robotic system – guided by the fair visitor – builds a rail system and runs a train on the route. While programming the task, the human can interact directly with the robot without a keyboard or touch panel.

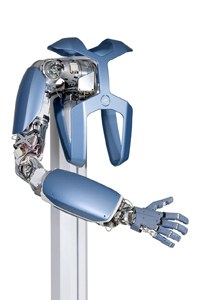

Hand arm system

Mechanical robustness and natural, highly dynamic movements are demonstrated by the anthropomorphic Hand Arm System. The robotic system is a human-inspired approach for direct physical interaction with humans, consisting of a five-finger hand with 19 degrees of freedom and an arm with 7 degrees of freedom. With its mechanical springs in all 26 degrees of freedom, collisions with the environment can be reduced thus avoiding damages to the robot and its environment. Furthermore, the spring elements can be used to store energy and thus enable highly dynamic movements while using less energy. The springs in the joints generate natural-seeming movements, illustrated by applications such as ball-throwing, drawing, manipulation of objects and tactile exploration.

Agile Justin

Agile Justin is a new member of the family of humanoid robots optimized for fast full-body movement based on the DLR’s lightweight technology. All of its 51 degrees of freedom – from the wheel to the fingertips – can be simultaneously controlled on torque levels. Combined with a rapid motion planner and the close interaction of all components due to a new version of the real-time capable software-middleware aRD, Agile Justin can carry out finely tuned, complex motion sequences. It demonstrates these abilities in an exemplary way by catching and returning a ball. A predecessor of this system was already nominated for the ICRA Best Video Award 2011.

Tele-present maintenance and repairs

An industrial-scale scenario for inspection, maintenance and repair in hazardous or hard-to-access industrial plants is being presented based on research with tele-operated aerospace robots. The multimodal (seeing, hearing, feeling) human-system interface allows an operator to intuitively remotely control a robot from a safe distance and to sense its sensor signals. Alongside the three-dimensional image, the two-handed force feedback with which the operator can feel the interaction forces as if he were performing the tasks themselves in place of the robot is an outstanding feature. This allows the operator to perform complex tasks in the remote environment, as demonstrated successfully in space experiments. The tele-operator is the humanoid torso SpaceJustin by the DLR, equipped with 47 degrees of freedom of movement as well as force and image sensors. It can grasp and use everyday components and tools with its hands. With its additional semi-autonomous functions, such as automatic scene analysis or repetition of manipulations, the robot assists humans in carrying out tasks.

Multifunctional cell by the ZLP

The DLR Center for Lightweight Production Technology (ZLP) in Augsburg is setting up the production technology research field for CRP lightweight structures in the industrial and science environment of the Augsburg Aerospace Area. With the resulting scientific competencies, ZLP, as a partner to industry, is making an essential contribution to the expansion of added value in the area of CRP primary structures. At the ZLP, a pilot plant is being set up to research and develop fully automatic production processes and to test end effectors in the field of fiber composite technology. An overall dynamic system model comprising all relevant subsystems was created for the development of model-based path planning algorithms and the system-dynamic analysis of positioning accuracy and oscillation behavior of the pilot plant in highly dynamic and cooperative operations.

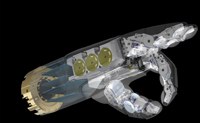

DEXHAND – space-qualified multi-finger hand

The DLR designed a space-qualified 4-finger hand for the ESA to support astronauts in their work in space in the future. The required performance with regard to gripping force and motion speed as well as the required small size is a special challenge to the design and the thermal system of the hand. The hand can be operated in automatic mode and via a data glove with force feedback.

Rigid force-torque sensor – FTS-100

The use of force-torque sensors like the FTS-100 enables a robot to more sensitively conduct tasks while installing, gluing, sanding or polishing. The FTS-100 sensor is based on a monolithic steel measuring body (“made of one piece”), laminated with strain gauge strips (DMS) according to a patented arrangement. The steel measuring body enables high-speed forces (Fx,Fy,Fz to 800N) and torques (Mx,My,Mz to 80Nm) to be measured with great precision. The analog and digital signal processing of the measured values is carried out on two separate electronic boards, which are accommodated completely in the sensor. A standard network cable (PoE – Power over EtherCAT) powers the inner electronics (netX50 processor) and ensures real-time capable EtherCAT communication. The measured data evaluation is possible with a maximum frequency of 5 kHz. Due to the compact design, the complete sensor with a weight of 1.3 kg can be accommodated in a cylinder with a diameter of 101 mm and a height of 40 mm.

Multi-sensor navigation system IPS

IPS (Integrated Positioning System) measures positions and locations in unknown environments (indoors and outdoors). It is based on a multi-sensor approach, which allows it to robustly and reliably register and transmit the six degrees of freedom of an object’s motion. The data from the multiple sensors are time-referenced and processed in real time by an integrated computer. If available, the system is supported via GNSS, enabling the embedding of the local navigation solution in a global spatial and temporal reference system.

A further developed and miniaturized version of the system is being presented at the AUTOMATICA for the first time.

Brain-controlled robotics

The use of robot assistance systems by paraplegic patients (see also http://www.brml.de) is made possible with new DLR technologies. In a unique experiment, DLR, in cooperation with partners in the USA, enabled a patient to control a DLR lightweight robot with her thoughts, for example, to be able to drink on her own again. We also use our novel learning methods for robot-assisted rehabilitation. The example shows how the measurement of muscle activity is sufficient to control a robot and its hand, in order to be able to move and grasp things accurately and agilely.

DLR-HIT five-finger hand

Based on DLR Hand II, scientists at the DLR and the Harbin Institute of Technology (HIT) have jointly developed a multisensory robot hand. The DLR-HIT hand presented here is a further development of DLR Hand II, which is recognized worldwide and the technical leader. Now commercially available, the DLR-HIT five-finger hand is a promising basis for future multisensory robot hands.

RoboDrive high-performance servomotors

The young and innovative firm RoboDrive distributes and develops lightweight torque-servo motors for a wide variety of applications. The drives originated from the lightweight robot developments of the RMC and are therefore especially suitable for applications requiring high performance density along with extreme precision and dynamics.

Aerospace technology for industry

SENSODRIVE is a spinoff of the German Aerospace Center. SENSODRIVE’s objective is to implement the latest drive technology developments in products. The firm specializes in its own and client-specific products developed using the latest methods of concurrent engineering and the foresight of mechatronics. As a system supplier with the highest standards of innovation and quality, manufacturers from the fields of aerospace, medical technology, simulator technology and automotive engineering count among its customers.

DUALIS MedTech

The MedBase basic technology uses the principle of inductive coupling to enable wireless transmission of energy and data for the operation of intelligent implants in the body. Due to different designs of the technology, it covers an energy spectrum of μWatt up to approx. 20 watts. The modular design also allows for efficient adaptation and integration of the technology.