Multiphysical Digital Twin

The concept of the Digital Twin unites all product-relevant information, such as development models, design data, manufacturing plans, maintenance information, and usage data from operation. The multiphysical Digital Twin goes even further by including dynamic behavior models, such as energy flows, mechanical movements, and heat generation, in which the product fulfills its technical function.

The Idea Behind it

The concept of the Digital Twin unites all product-relevant information, such as development models, design data, manufacturing plans, maintenance information, and usage data from operation.

The multiphysical Digital Twin goes even further by including dynamic behavior models, such as energy flows, mechanical movements, and heat generation, in which the product fulfills its technical function. Thus, specifications, production and usage history, data streams, and more are unified within a functional virtual representation, accurately reflecting the product’s physical and operational characteristics. This approach enables the design, engineering, and optimization of the product over its entire lifecycle: from development, commissioning, and operational deployment to modification and recycling/upcycling. This allows for improved performance, safety, resource efficiency, costs, individualized and rapid adaptation to changing market requirements, and operational efficiency

The Structure of the System

To manage this diversity, the scientific goal is to develop technologies for providing multiphysical Digital Twins of products and product families in a structured manner, using modular sets of models and methods, so that they can be swiftly introduced and used by all relevant departments in an industrial setting.

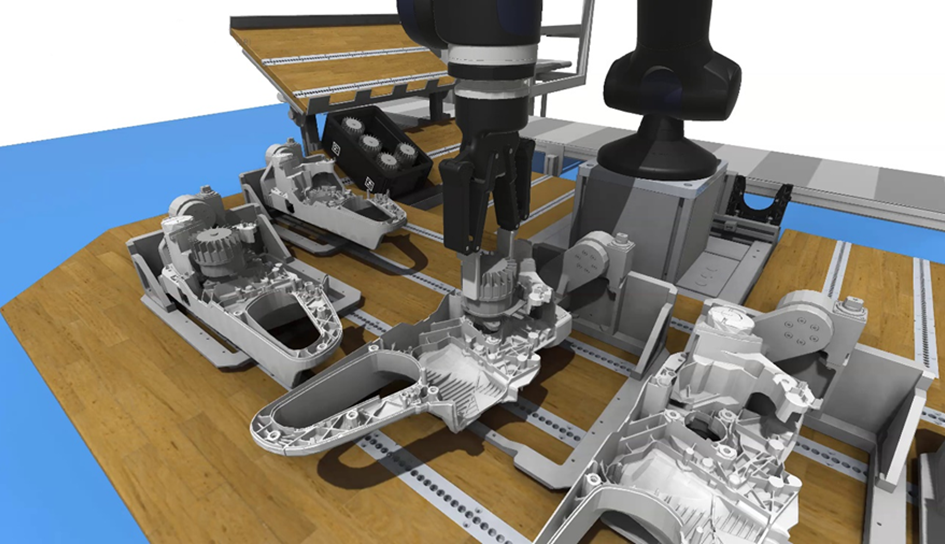

These toolkits, which are based on open standards, allow for the synthesis of specific processes by combining and assembling individual models and methods. The Modelica language, an open standard for modeling complex multiphysical systems, serves as the primary tool for modeling, while the Functional Mock-up Interface (FMI) standard is used for model exchange and co-simulation. A key research direction involves improving Modelica's applicability for simulating robotic assembly tasks. This is achieved by developing variable fidelity libraries for robot dynamics, manipulation, and control, alongside interfaces for industrial communication like OPC UA and EtherCAT. This approach provides a spectrum of models, ranging from computationally lightweight, real-time capable models to physically accurate, high-fidelity offline models.

Applications

The muliphysical Digital Twin enables a wide range of applications. For example, by linking virtual hardware with real control systems, software and hardware development can be parallelized. The use of digital prototypes during virtual commissioning reduces the likelihood of unforeseen events occurring during on-site commissioning at the customer.

Generating virtual sensor data allows for the rigorous testing of fault cases and complex operational processes early in the development cycle. This form of virtual validation can occur long before hardware is finalized, preventing costly late-stage design modifications. Furthermore, data from the digital twin fuels model-based optimization of product parameters, operating strategies, and designs to achieve maximum performance and efficiency.

Developed systems showcase these capabilities, ranging from high-fidelity dynamic models for robotic assembly tasks to large-scale, system-of-systems models of OPC-UA-orchestrated aircraft production scenarios.