HUG

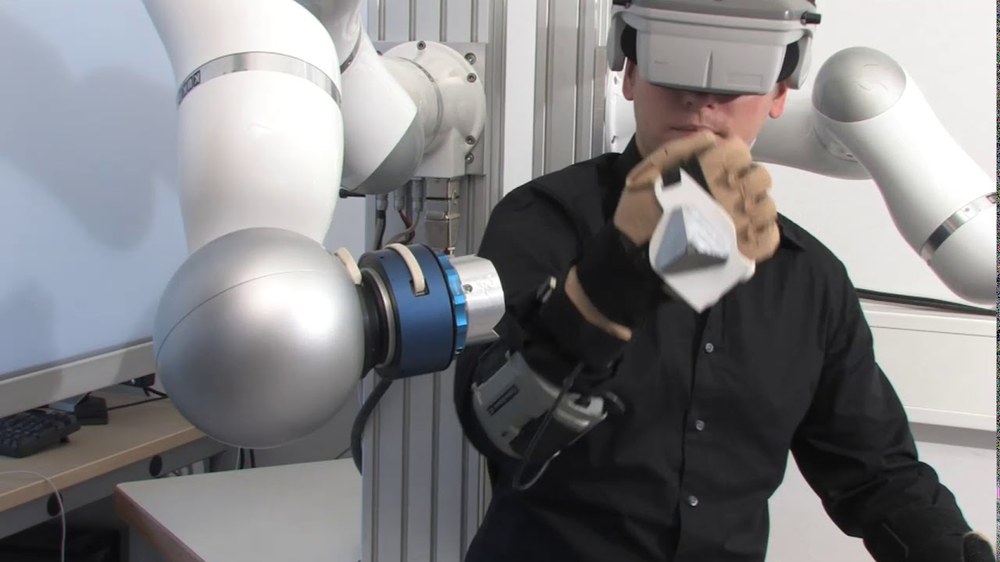

HUG is the haptic user interface for telemanipulating our humanoid robot Justin. With its two light-weight robot arms, HUG can precisely measure the movements conducted by the human operator and at the same time display the forces that occur in the distant environment.

The robotic system HUG was presented to the public for the first time in 2010.

Technical data

Size: |

|

Weight: | approx. 50 kg (of which 2 x 10 kg are dynamic mass) |

Degrees of freedom: | 2 × 7 |

Nominal payload: | 20 kg |

Sensors: |

|

Special features: |

|

System description

How to achieve the most realistic force-feedback for our sophisticated haptic applications? This was one of the core questions when developing HUG. HUG is a bimanual haptic device composed of two Light-Weight Robot arms. The two robots are mounted behind the user, such that the intersecting workspace of the robots and the human arms becomes maximal. Equipped with a thorough safety architecture in hard- and software, HUG assures safe operation for human and robot.

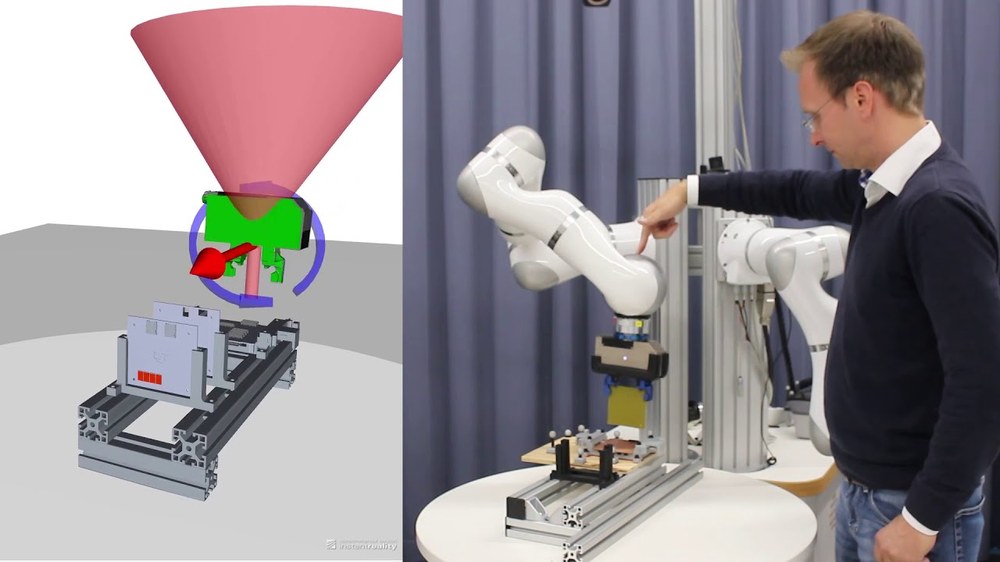

A particularly advantageous characteristic of HUG is its capability of generating high interaction forces in a comparably large workspace. Various hand interfaces and additional vibro-tactile feedback devices are available to enhance user interaction. Additionally, sophisticated control strategies improve performance and guarantee stability. To this end, HUG is well suited for versatile applications in remote and virtual environments:

- Telemanipulation of SpaceJustin

- Virtual assembly verification with haptic feedback

- Training of astronauts and mechanics

- Rehabilitation

Video: Space Factory 4.0 Telerobotic Assembly of Cubesats using Virtual Fixtures

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

Video: The DLR Bimanual Haptic Device

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

Related publications

- J. Vogel, D. Leidner, A. Hagengruber, M. Panzirsch, B. Bäuml, M. Denninger, U. Hillenbrand, L. Suchenwirth, et al.: An Ecosystem for Heterogeneous Robotic Assistants in Caregiving, IEEE Robotics and Automation Magazine, 2021 (accepted)

- M. Sagardia, T. Hulin, K. Hertkorn, P. Kremer, S. Schätzle: A Platform for Bimanual Virtual Assembly Training with Haptic Feedback in Large Multi-Object Environments, ACM VRST 2016, Munich, Germany, 2016.

- T. Hulin, K. Hertkorn, P. Kremer, S. Schätzle, J. Artigas, M. Sagardia, F. Zacharias, C. Preusche: The DLR Bimanual Haptic Device with Optimized Workspace (Video), ICRA2011, Shanghai, China, 2011.

- T. Hulin, M. Sagardia, J. Artigas, S. Schätzle, P. Kremer, C. Preusche: Human-Scale Bimanual Haptic Interface, Enactive08, Pisa, Italy, 2008.