Sul4Fuel

Hydrogen in the zinc/sulphur industry: development of a pilot plant for SO2-depolarised electrolysis

Duration: 1.9.2022 - 31.8.2026

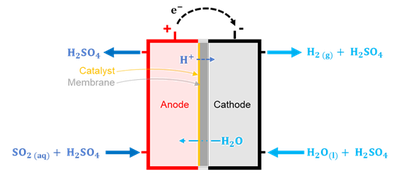

Industry in Germany is in part particularly energy-intensive and is one of the largest emitters of greenhouse gases. The decarbonisation of industry is therefore a decisive step towards achieving climate targets and a sustainable economy. One possible solution could be SO2-depolarised electrolysis (SDE). In this process, hydrogen and sulphuric acid can be produced using sulphur dioxide. In the Sul4Fuel project, this is to be tested in the zinc/sulphuric acid recycling industry – with the aim of creating a climate-neutral alternative to existing processes.

SO2-depolarised electrolysis is based on polymer electrolyte membrane (PEM) electrolysis technology for water splitting. It is a promising electrolysis process for producing hydrogen and sulphuric acid from an SO2/H2O mixture. This process is particularly thermodynamically efficient and enables the production of sulphuric acid, which is used directly in a process for treating zinc-containing waste as part of the circular economy. The hydrogen can then be used to replace fossil fuels in sulphuric acid recycling.

Realisation on an industrial scale

This is because sulphuric acid is produced as a waste product in the chemical industry. Grillo utilises this used sulphuric acid and processes it further at its Duisburg site. The sulphuric acid is split at high temperatures to produce sulphur dioxide. However, the chemical process requires operating temperatures of more than 1,000 degrees Celsius, which until now have been generated by burning fossil fuels. To replace these, the hydrogen produced by the SDE can be utilised. The result is a circular economy.

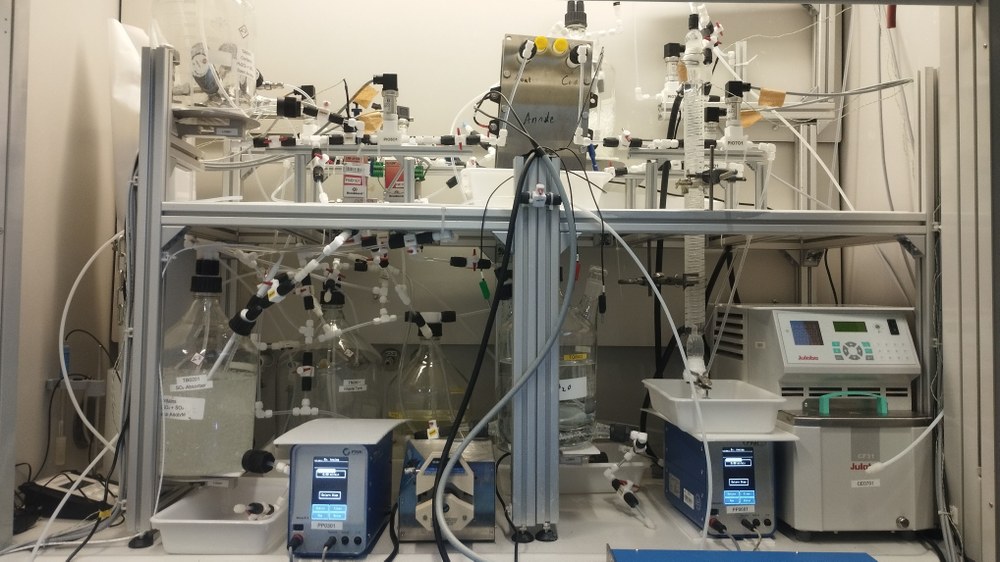

As part of the Sul4Fuel project, the innovative technology is to be trialled on an industrial scale. The SDE technology must be further developed for this purpose. It has so far been trialled at Aalto University in Finland with a technology readiness level (TRL) of four to five. This corresponds to a test setup in the laboratory and a test setup in the operating environment. The project aims to realise this on a pilot scale and achieve a TRL of six to seven, which corresponds to a prototype in the operating environment and a prototype in use (1-5 years). The project team intends to realise this at the Grillo plants in Duisburg.

The aim of the project is to upscale an SDE electrolyser. At the same time, the project team is discussing possible paths for its commercial use. The project will advance the technology and open up new possibilities for the efficient production of hydrogen.

Commercial applications

From Grillo AG's point of view, the results obtained can be transferred to other industries with a wide variety of SO2 sources. The main focus here is on the global production of non-ferrous metals such as lead, zinc and copper. This is because a great deal of effort is made in the sulphuric acid plant that is usually installed downstream in order to homogenise the SO2 gas flows on the one hand and to reduce the total turnover of SO2 to emission values that comply with licensing requirements on the other. According to the Sul4Fuel approach, an SO2-laden gas stream can be extracted instead in order to produce the products sulphuric acid and hydrogen.

If the technology is successfully developed, Hugo Petersen GmbH believes that it can also be used to utilise SO2 from a wide variety of gas sources. In particular, its use in secondary gases from non-ferrous metal smelting or in sulphuric acid plants with reduced conversion after V2O5 contacts is conceivable. The sulphuric acid produced would be used as a dilution medium in the classic sulphuric acid contact plant.

The innovative approach of the Sul4Fuel project enables various commercial applications and can create a climate-neutral alternative in order to come closer to the goal of decarbonising the industry.

Project | Sul4Fuel |

|---|---|

Duration | 1.9.2022 - 31.8.2026 |

Projekt participants |

|

Funding | Funded by the Federal Ministry of Economic Affairs and Energy. |

Contact

Dennis Thomey