Evaluation of solar production processes

Helmholtz-Klima-Initiative / Julia Blenn, DLR / Tanja Hildebrandt

The department evaluation of solar production processes analyses and evaluates different processes for the production of CO2-neutral fuels and base materials based on solar energy. The logistical concepts underlying the provision of the required raw materials and the transport and distribution of the fuels are also analysed. The results of the evaluations support decision-making processes and show possible courses of action for the optimal integration of solar fuel production into a global market. Decision-makers thus receive scientifically sound guidance, an important contribution to decision-making in energy and fuel policy.

The aim of the department is to identify the most promising production routes for CO2-neutral fuels and base materials of the future in terms of costs and emissions and to evaluate them systematically. This should help to optimise the integration of solar fuel production into a global market and achieve broad acceptance and application of solar fuels in future society. The goal: a renewable energy economy.

Solar production processes and methods are evaluated from an economic, technical, ecological and social perspective. The studies take a comprehensive and holistic view of all key influencing factors.

Main areas of work

The researchers in the department evaluation of solar production processes are initially developing the methods and tools that they use for studies and for the evaluation of specific solar fuels and production processes. The processes we are analysing include solar thermochemical cycles, solar-powered high-temperature electrolysis and all processes that are coupled with solar heat. Downstream processes such as Fischer-Tropsch synthesis or methanol-to-gasoline processes are also being analysed. In process analyses, the researchers also examine the origin of the educts, such as water and CO2, which are obtained from point sources such as cement production or direct air capture plants, for example, and look at the meteorological data from locations all over the world. Hydrogen, methanol, ammonia, synthesis gas, sulphur, Sustainable Aviation Fuels (SAF) and other synthetic fuels and chemical feedstocks are considered as end products.

The focus is on techno-economic evaluation, ecological analysis and socio-economic analysis.

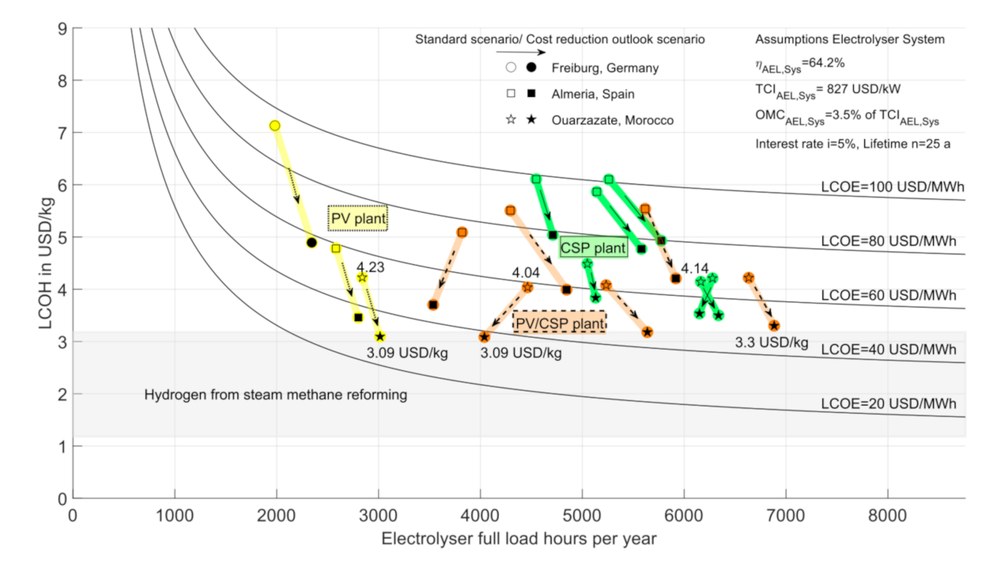

- The techno-economic evaluation identifies the economic potential of solar fuel production processes and the impact of key components.

- The Life Cycle Assessment (LCA) is used to analyse the ecological impact of solar processes.

- The final step is a socio-economic evaluation of the processes.

Based on our assessments, we want to provide knowledge that will help to make the production processes for various fuels and base materials more cost-effective and environmentally friendly by utilising solar energy (CSP, PV) and coupling it with other renewable energies.