Rapid Control Prototyping in a HiL-Optimization Environment

As the main aim for control engineers in the field of industrial robotic is basically to enhance velocity and accuracy of the treated structure, more and more powerful systems for the design and optimization process are developed. In the case of our control department, rapid control prototyping is executed with simulation programs like MODELICA/DYMOLA on the one hand and optimization tools as MOPS (Multi-Objective Parameter Synthesis) embedded in the real time environment Matlab-xPC on the other. The term “rapid control prototyping” thereby means the fast and efficient development of control tasks, starting at the model building and ending at the hardware-in-the-loop (Hil) optimization of the designed controller structure.

Due to the fact that manual tuning of controller parameters for achieving high performance controllers is very time consuming this HiL (Hardware in the Loop)-setup has been built up. Using different criteria (for example overshoot, settling time, or position error) which can be calculated from the measured data many different, often conflicting requirements can be considered. The optimisation technology for this automatic process is the above mentioned, Matlab-based program MOPS which has originally been designed at the DLR for advanced robust flight control problems.

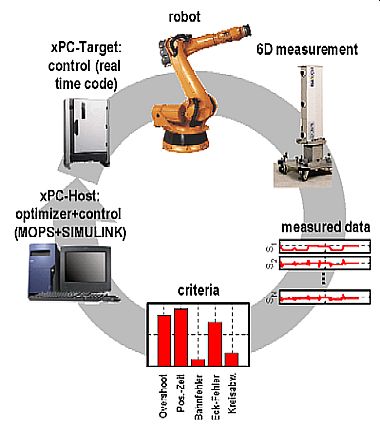

The experiment setup is shown schematically in the figure. Based on the above described compo-nents an optimization cycle proceeds as follows:

A SIMULINK model – SIMULINK is a graphical toolbox of the simulation package Matlab – of the controller in combination with the optimizer runs on the xPC-Host. Real time code of the controller which is generated automatically from Matlab is sent to the xPC-Target in the control unit of the robot. Parallel to the movement of the robot a 6-degrees-of-freedom camera measures the position and orientation e.g. of the robot flange. These data are read in by the xPC-Host and afterwards the optimizer calculates the above mentioned criteria as well as new controller parameters which are sent back to the xPC-Target in real time.

This ensures that control engineers can test their designed structures in a very efficient way.