Institute of Solar Research

The Institute of Solar Research develops concentrating solar systems for the generation of heat, power and fuel.

Sproetniek

Duration: 1.1.2023 - 31.12.2025

SOLHYKO is investigating innovative processes for the sustainable production of hydrogen (H2) and synthetic fuels such as kerosene or marine diesel using solar energy. The aim is to make demanding transport sectors such as aviation, shipping and heavy-duty road transport independent of fossil fuels in line with international climate targets.

The focus is on two solar thermal processes for utilizing solar high-temperature heat: the thermochemical cycle with a monolithic redox pore body or with redox particles, and solar reforming. These processes use concentrated solar radiation to split water vapor (H2O) into hydrogen and oxygen or to obtain a synthesis gas from hydrogen and carbon monoxide (CO) from biogas. From these products, alternative fuels can then be produced that have a high energy density compared to today's battery technology.

One advantage of these processes is that solar heat can be used directly for the fission process, without the detour of producing electricity. The unique testing possibilities in the large-scale concentrated solar radiation facilities of the German Aerospace Center (DLR) are what make this research possible in the first place.

The SOLHYKO research project focuses on the production of sustainable fuels through solar thermal processes. Receivers (for heat generation) and reactors (for chemical reactions) are optimized in the laboratory and scaled up to industrial scale using mathematical models.

The researchers are gaining new insights into system design, operating behavior, material aging and energy efficiency, and incorporating these into further development steps. The Synlight solar simulator from the DLR, which is used to research the use of concentrated solar radiation, makes it possible to generate artificial sunlight under constant conditions in order to optimize solar thermal processes in experiments.

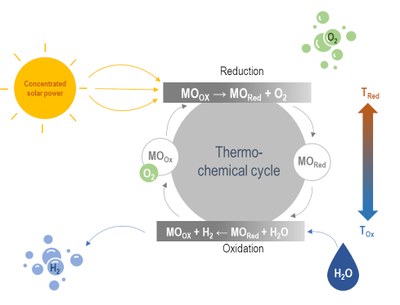

A redox cycle for solar hydrogen production uses concentrated solar radiation to trigger chemical reactions in special materials known as redox materials. The aim is to obtain hydrogen, for example, by thermochemical splitting of water vapor, in which the redox material is cyclically reduced and oxidized.

The materials used are metal oxides that release oxygen at very high temperatures of up to 1.500 degrees Celsius (reduction). At lower temperatures and in the presence of water vapor, the materials absorb oxygen again (oxidation). In doing so, they release and bind the oxygen from the water molecule. The released hydrogen remains and is collected as a product. The recurring cycles use only water and heat from concentrated solar radiation. The high and changing temperature levels of over 1.000 degrees Celsius are particularly challenging from a technical point of view.

Inspired by Net-Zero Web-Atlas (atlas.netto-null.org)

Hydrogen can then be used as a direct fuel or as a raw material for the further production of synthetic fuels. In a slightly modified form, the redox process can also use biogas to produce a gas mixture of hydrogen and carbon monoxide. This synthesis gas, which already contains all the components needed to produce synthetic fuels, is thus available after a single conversion step.

Another method for the direct production of synthesis gas is the solar reforming of biogas. In this process, the main components of the renewable starting material – methane (CH4) and carbon dioxide (CO2) – react with steam on a catalyst. Here, too, concentrated solar radiation provides the heat required for the reactions at high temperatures.

Conventional natural gas reforming is used as a reference here. However, in this process, fossil fuels are used both as the starting material and for heat supply. In contrast to this industrially established process, solar reforming of biogas offers the potential to drastically reduce the CO2 footprint and to make an important contribution to the production of carbon-neutral fuels.

Within the SOLHYKO project, two innovative redox reactor concepts and the solar reforming of biogas are being further developed and their potentials compared. One focus is on the optimization of the materials used through their more precise characterization, targeted selection and improved production. Another focus of the research is the efficient transfer of heat to the redox materials despite high temperatures. All production processes are demonstrated on a laboratory scale.

In addition, the researchers are developing detailed reactor models using mathematical methods. These are used to simulate reactor behavior in interaction with other plant components for hydrogen and hydrocarbon production. Particular emphasis is placed on the theoretical scaling of the laboratory models to an industrial scale. System-wide energy flows and operating strategies are optimized to improve the efficiency of fuel production.

In a further step, an economic and ecological evaluation of the processes for solar fuel production is carried out. Particular attention is paid here to the potential for reducing the final fuel costs and to the environmental impacts over the life cycle of the plants. Finally, both the market potential of the production processes and of the solar fuels are evaluated in order to identify possible producing countries and sales markets.

The demand for renewable fuels and chemicals will increase rapidly in the coming decades and create a sector that will reach volumes comparable to those of today's fossil fuels in the second half of the century. The SOLHYKO project is making a significant contribution to the development of technology for solar production processes on an industrial scale. To this end, several DLR institutes with world-leading experience in the field of solar research are cooperating with each other.

A close exchange with companies from the fields of concentrating solar technology, plant engineering and the chemical industry as well as the energy sector enables the research work to be optimally aligned with the pressing issues in the industry. Among other things, the intended project results are aimed at improving key components and increasing efficiency through intelligent process integration along the value chain.

Project | SOLHYKO |

|---|---|

Duration | 1.1.2023 - 31.12.2025 |

Project participants |

|

Funding | Basic funding of the DLR |