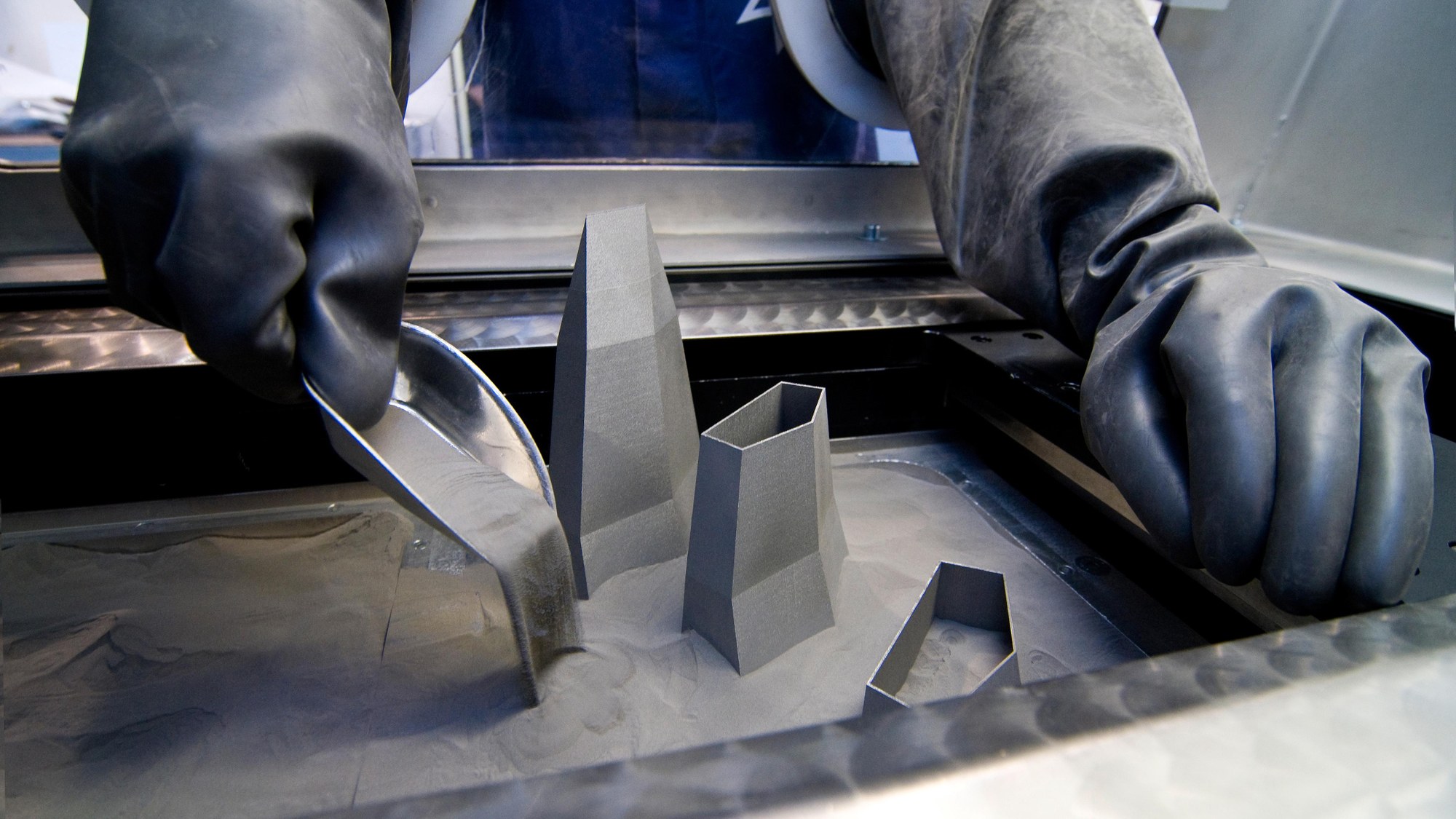

Modelling with powder

Modelling with powder

The LaserCUSING process involves the fusion of single-component metallic powders using a laser, allowing components to be built up layer by layer from almost any metallic material using 3D computer generated data. The laser beam locally fuses a single-powder material layer by layer. The laser’s rapid movement means the workpiece is scarcely heated, the melt cools down quickly and the possibilities of component distortion are minimized. The parts made from the powder cannot be distinguished from a solid piece of metal.