"European aviation must stay competitive"

DLR/Zana Jozeljic

Clean Sky 2 was Europe's largest aviation research programme. Over ten years, DLR explored potential solutions for climate-neutral aviation. What was this major research programme about?

Clean Sky 2, its predecessor Clean Sky and its successor Clean Aviation (launched in 2023), are major initiatives of the European Commission. The core idea behind these programmes is to ensure that European aviation remains competitive and becomes climate-neutral by 2050. At the start of Clean Sky, about 20 years ago, we realised that while we were conducting a great deal of research, we lacked large-scale flight experiments or integrated prototypes – known as demonstrators. To close this gap, more than 800 European aviation organisations joined forces to work on these research programmes – ranging from large industrial companies to small- and medium-sized enterprises, universities and research organisations like DLR. Clean Sky 2 was funded with 1.7 billion euros, with DLR, – the fifth-largest recipient – granted over 80 million euros. This funding supported the development of more than 100 demonstrators and approximately 1000 technologies across nine main projects. In total, DLR has been involved in 27 projects.

Can you give some examples?

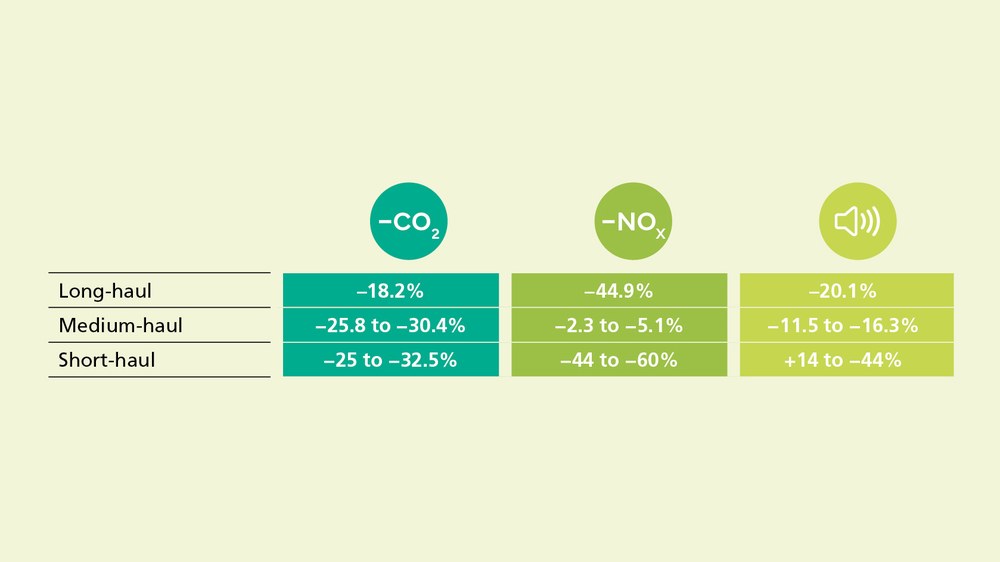

We conducted research into solutions for commercial aircraft, business jets and even helicopters. This included the aircraft themselves, but also their components – wings, fuselage, tail units, engines and cabins. The programme also looked at production technology, simulation processes and improving measurement techniques. Our research into laminar flow during cruise flight proved particularly interesting. When flying, we ideally want a high level of laminar flow – that is, minimal frictional resistance – over the wings or engine nacelles. If components can be designed in such a way that they are surrounded by laminar rather than turbulent airflow, this reduces drag and fuel consumption. Another project, the Multi-Functional Fuselage Demonstrator (MFFD), aimed at reducing the weight of the fuselage and enabling automated production, with DLR playing a prominent role. In fact, the fuselage demonstrator was awarded the prestigious JEC Composites Innovation Award in early 2025. DLR was also responsible for the overarching task of analysing and evaluating all the technology contributing to Clean Sky 2. These findings are compiled using the 'Technology Evaluator'.

That's quite a lot! Which are your favourite results?

In addition to the RACER helicopter and MFFD, the installation and commissioning of the compressor test bench as part of the 2ShaftCompressor project were stand-out moments personally for me. With hardware developed at DLR in Cologne, we created an essential test facility for German industry – just like the new turbine test bench in Göttingen. Achieving all of this within the timeframe of the programme was a mammoth task, but we made it happen.

Another example was our work on the 'laminarisation' of commercial aircraft in collaboration with Airbus and Dassault. This technology had not yet been developed far enough to represent a viable business case – so, a worthwhile investment – or to be integrated into production aircraft. We've come a long way in this area to make that possible.

I was also particularly impressed to see our ISTAR research aircraft flying with artificial icing, in collaboration with Dassault. Ice buildup on the leading edges of aircraft wings is dangerous and can render aircraft unmanoeuvrable, so strict certification regulations have been introduced to address this. We used ISTAR to perform in-flight measurements showing how flight characteristics and performance change due to simulated icing. While flights with ice accretion had been conducted during the certification of this aircraft type, Dassault did not collect data on control or performance changes. Our new data forms the basis for comparing the real-life behaviour of aircraft under icing conditions with digital simulations. In the future, this could allow some certifications to be carried out by computer simulation, saving many costly and dangerous flight test hours.

Which results do you think will have the most significant impact on aviation?

Take the aircraft market: an A320 can remain in service for up to 40 years, meaning the product and innovation cycles are correspondingly long. For a new aircraft generation to be launched successfully, sufficient gains in weight reduction, drag reduction and fuel savings are particularly promising. Production costs also play an important role. Back to our aircraft – while a new flap design on the wing can be implemented relatively quickly, a hybrid laminar system has to be part of a completely new wing design – a major financial risk for manufacturers. Through our work and developments, we’ve been able to demonstrate the conditions under which such a system can be operated economically.

DLR/Zana Joseljic

What's your takeaway from Clean Sky 2?

I'd say that we – and by that I mean all DLR employees involved in Clean Sky 2 – fulfilled our task 110 percent. We solved problems and significantly advanced technologies so that manufacturers can integrate them into their aircraft. Whether everything comes into fruition will depend on factors like global market competition – which is out of DLR's hands.

One challenge in Europe will be to offer new, environmentally compatible aircraft which consume less fuel – at competitive prices. I'm noticing that manufacturers are starting to properly consider environmental impact now that they have a host of promising new technologies at their disposal that will enable them to implement this step economically. The aeronautics community has once again shown that we can achieve a lot in Europe if we pull together.

How will the public benefit from the programme?

The next generation of commercial aircraft, which will come onto the market from around 2035, will incorporate many of the technologies developed in Clean Sky and Clean Sky 2. I'm certain of that. In concrete terms, it could be that the outer part of the wing on a new commercial aircraft replacing the A320 may benefit from laminar flow to reduce drag. There will be new types of engines that are larger and more efficient. This will result in quieter cabins due to measures like active noise cancelling – thanks to a technique you may be familiar with from your headphones – and structural changes that prevent sound from spreading from its source into the cabin. DLR has also been working on new materials and production techniques that could reduce costs. Ultimately, our research is geared towards making aircraft so environmentally compatible that air travel in the future will be possible even under more stringent environmental regulations.

Clean Aviation, the successor programme, is already underway ...

If aviation is to be climate neutral by 2050, the key decisions and concepts must be finalised by 2035. That's quite soon, so that's what the Clean Aviation programme is focusing on. As such, our research these days isn't geared towards helicopters or business jets; instead, the focus is on commercial aircraft and their engines. We're doing less research on cabins and wings but looking more at overall systems. To bring new aircraft into service as quickly as possible, Clean Aviation is also involved in the certification of new technologies from the very outset.

Are you once again coordinating the project at DLR?

Yes – I see my role as something like clearing a trail through the EU jungle. It's wonderful to work with so many highly motivated people, and I want to ensure that they get the resources they need to turn their constructive ideas into environmentally compatible and viable technologies together with European stakeholders.

Technology Evaluator

An article by Julia Heil from the DLRmagazine 177