Structural health monitoring allows detection of damage to aircraft components made of CFRP

Components made of Carbon Fibre Reinforced Polymers (CFRP) are increasingly being used to make aircraft lighter, more comfortable and more economical. In order to make these aircraft even safer and facilitate their maintenance, the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) has built a large aircraft component out of CFRP, as part of the EU Smart Intelligent Airframe Structures (SARISTU) project. The component can provide information about the size and location of any damage.

"Just as a person notices an injury, the component detects where and to what extent it has been damaged," says Daniel Schmidt of the DLR Institute of Composite Structures and Adaptive Systems. This detection and localisation of damage is called 'Structural Health Monitoring' (SHM). The benefits will be that, in future, a defective part will no longer need to be removed and extensively examined, maintenance and repair will be easier and no damage will go undetected, thereby improving safety and reducing costs.

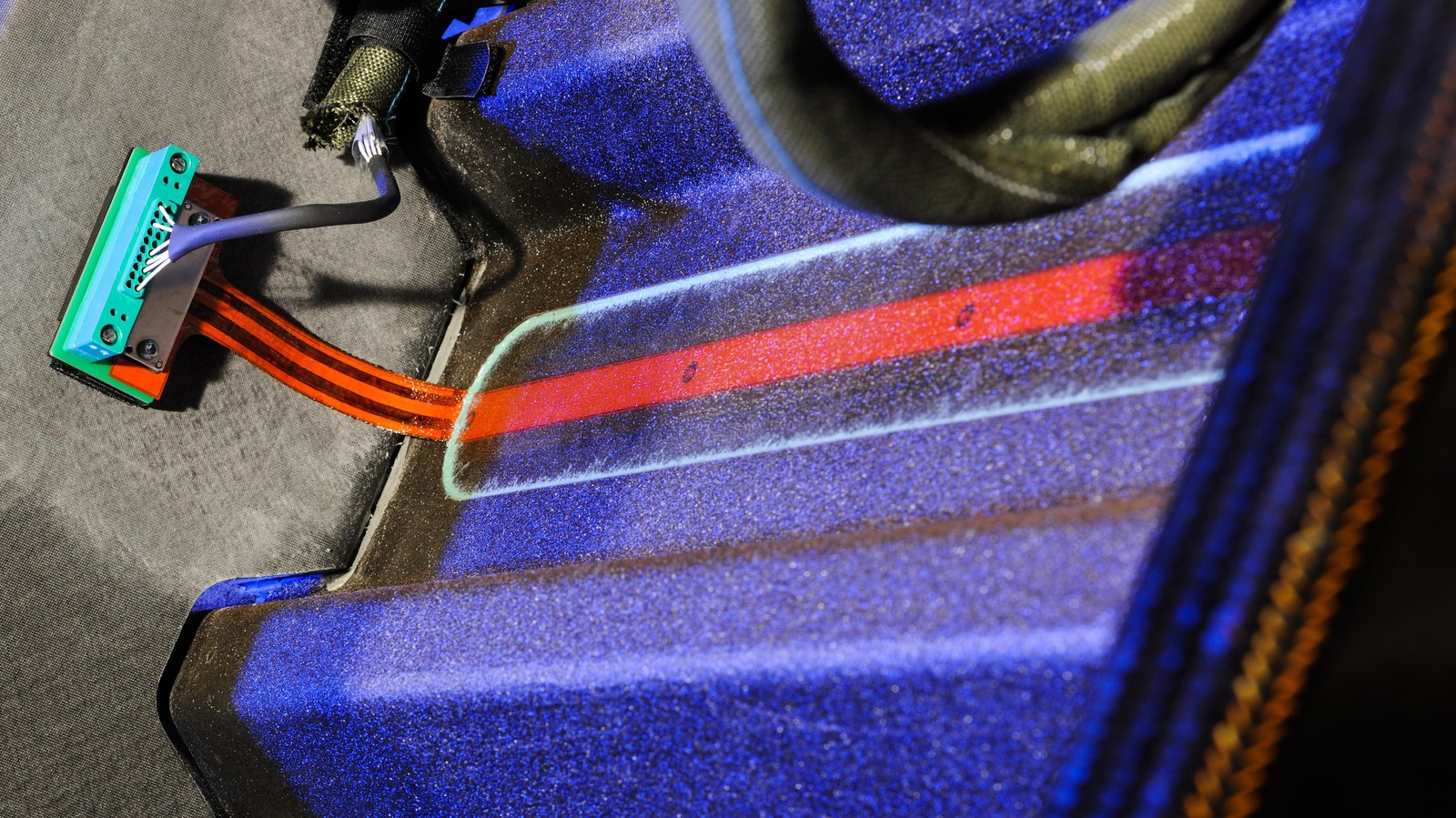

'Nerves' and 'brain' for an aircraft component

To enable SHM testing, the CFRP component has been equipped with a kind of 'nervous system'. 584 sensors have been integrated into a five by seven metre fuselage section surrounding a passenger door. This is currently the world’s largest and most complex structure on which a SHM system has been tested. Unlike before, the sensors are not glued to the surface, but have been integrated directly into the material, thereby reducing manufacturing costs. If an aircraft sustains any damage due to an impact during loading, for example, in future there will be no need to call a technician to detect the damage. At the touch of a button, the structure will provide information about the location and nature of the damage. "This is made possible by Lamb waves," explains Schmidt. "Lamb waves are special ultrasonic waves that propagate extensively within the structure. Damage causes signal changes that can be observed in the Lamb waves."

Joint research with Airbus

The structure surrounding the door was chosen because this is where damage is most likely to occur. DLR has developed a sensor network that is robust enough to survive the manufacturing process. The research project was led by Airbus and involved a number of European partners. In order for the vision of the sentient aircraft structure to become reality, the on-going research work with Airbus is focused on making the SHM system suitable for the real-life operation of an aircraft. The other project partners are INVENT GmbH, FACC Operations GmbH, Airbus Group Innovations and Airbus Operations GmbH.