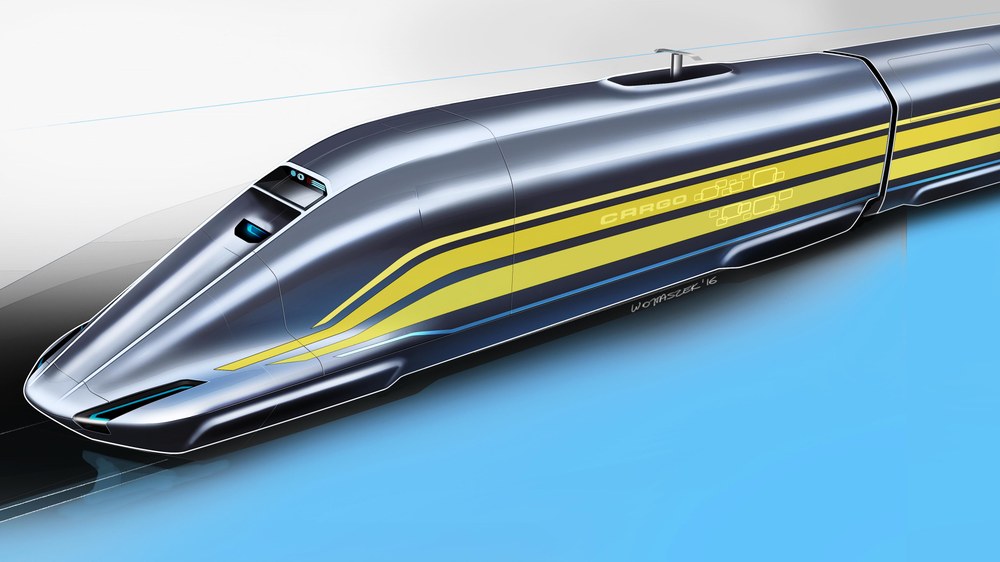

NGT CARGO: What freight trains of the future will look like

- NGT CARGO is an innovative and integral concept, designed to increase the attractiveness of rail freight transport.

- The automated NGT CARGO trains will be assembled from single wagons and end cars to suit requirements, therefore allowing flexible, resource-saving, rapid and reliable transport for all kinds of goods.

- The smart single wagons are fitted with their own electric drive systems and can travel automatically and autonomously the final kilometres to the customer.

Transport researchers at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) have developed an innovative, holistic locomotive concept – the NGT CARGO. The concept aims to make European rail freight more appealing and hence increase its market share. It is distinguished by a high level of automation, intelligent handling and high speeds. In this way, rail freight transportation can be made more flexible and the capacity of the system can be increased.

Rail freight traffic in the overall transport volume does not increase. The politically intended displacement of freight traffic from road to rail is not happening. At the same time, freight traffic will continue to increase, in Germany alone by almost 40 percent by 2030. "This makes it all the more important that we develop innovative logistics, production and vehicle concepts such as NGT CARGO, to exploit the societal, ecological and economic benefits of rail freight transport," explains DLR researcher Joachim Winter, who is leading the Next Generation Train (NGT) project.

Freight transport à la carte – faster, more flexible, more efficient

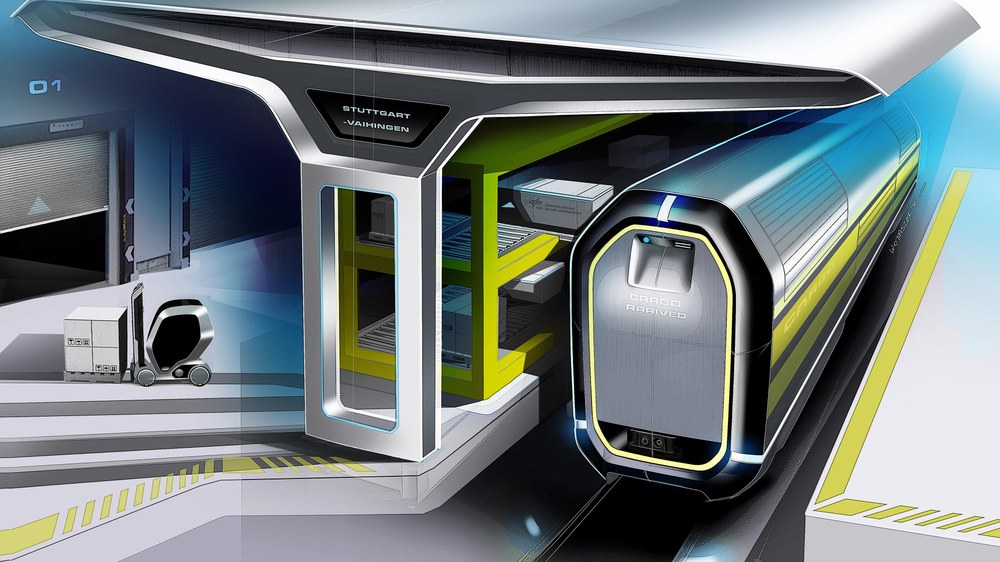

The automatically driven NGT CARGO trains will be made up of single wagons and powerful end cars, automatically coupled together as required. "In this way, we can transport a vast range of goods flexibly, and with low use of resources, minimal deployment of personnel and short transport times," says Winter, summarising the key benefits of the concept. As the transportation of small-scale shipments in particular will increase significantly in the future, DLR scientists are focusing on fast, reliable freight transport.

"Freight transport is currently dominated by block trains that are not shunted and that use a large number of wagons to carry large, standard volumes of freight from point A to point B," summarises Winter. This is because, until now, a very elaborate process using rigid operating procedures underlies single wagon transport. Coupling and uncoupling wagons, picking them up and delivering them is very time- and resource-intensive and account for 30 to 40 percent of the overall costs. A large number of manual coupling processes leads to long idle periods for individual wagons and an average system speed of just 18 kilometres per hour for single-wagon transport. A lead time of approximately five days is required to make the personnel, material and routes available.

To make single-wagon transport fit for the future, intelligent freight wagons in the NGT CARGO concept have a separate drive based on electric motors and a battery that stores energy recovered during braking. This makes it possible for the single wagons to shunt autonomously, without the need for shunting staff and shunting locomotives or overhead lines. Furthermore, the individual wagons can travel the final kilometres to the respective customer automatically and autonomously. Each single wagon is equipped with the appropriate sensors to do so. So, for example, it can be located at all times and customers can have precise details about the current status and expected arrival time of their freight. The wagons can also be driven directly into ports, transshipment stations or logistics terminals, right up to the high level racks, where they are also then loaded or unloaded automatically.

High speeds and optimum line usage

For operation in the high speed range, the NGT CARGO single wagons form a unit and are combined with one or two end cars to form a complete locomotive. The end cars provide the necessary drive. With the appropriate infrastructure, up to 400 kilometres per hour is conceivable; on existing lines, speeds of up to 160 or 200 kilometres per hour. "One interesting application scenario for the NGT CARGO would be intercontinental freight traffic between Europe and Asia, as an alternative to transport using container ships that have long sea routes and little flexibility in terms of freight volume, as they carry very large containers.

Multiple locomotives can be combined virtually during travel (called dynamic coupling). By doing so they form a block train, although they are not physically coupled to one another. Combination with the NGT HST high-speed passenger train is also possible. In this way, the DLR researchers aim to combine passenger and goods transportation to enable existing line capacities to be used optimally.

Following presentation of the basic concept for the NGT CARGO, the DLR researchers are now working on developing a detailed logistics and operating concept, designing terminals and unloading sites and improving the vehicle architecture and drive concept. In contrast to the wagons currently in use, the NGT CARGO wagons will be enclosed and aerodynamically covered. There will be no gaps between the single wagons, reducing wind resistance and generating less noise.

The DLR Next Generation Train (NGT) Project

For approximately 10 years, DLR transport research has been investigating and developing future-oriented train concepts under the Next Generation Train (NGT) project. The main goals have been to reduce travel and transport costs, save energy and reduce noise emissions, increase passenger comfort, improve travel safety and minimise the lifecycle costs of the rolling stock. The NGT train family consists of the NGT CARGO, the NGT HST high-speed locomotive, which can reach speeds of up to 400 kilometres per hour on suitable tracks, and the NGT LINK, a fast Intercity locomotive that can reach up to 230 kilometres per hour and is expected to transport passengers from the hinterland to main railway stations on high-speed lines.