DLR at JEC 2018 in Paris

- DLR will be presenting technologies for the digitalised production of fibre composite components at JEC World 2018 in Paris from 6 to 8 March 2018.

- DLR stand in Hall 5a.

- Focal point (s): aeronautics, transport, lightweight construction

The German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) will present its latest research projects on the topic of high-performance fibre-reinforced polymers from 6 to 8 March 2018 at JEC World in Paris – the leading European composites trade fair. This year, the focus of the joint appearance by the DLR Institute of Composite Structures and Adaptive Systems, the To the Institute's website (ZLP) in Stade, the DLR Simulation and Software Technology facility and the DLR Institute of Structures and Design will be innovative technologies for the digitalised production of fibre-composite components. On the approximately 80-square-metre DLR stand in Hall 5a (E66), researchers will showcase and explain various examples of applications, especially for the aerospace industry.

Digital factory for the production of the future

The fully automated process chain for the manufacture of fibre-composite components using Resin Transfer Moulding (RTM) technology at DLR Stade is being upgraded to a cyber-physical system by the creation of a digital ‘twin’, in order to virtually monitor real production. People, objects and systems will interact here in the near future. The possibilities of dynamic, real-time capable and self-organising production are being explored. Visitors to the trade fair can immerse themselves in the virtual reality factory and gain an impression of future application scenarios, such as remote maintenance or supervision via a virtual control centre.

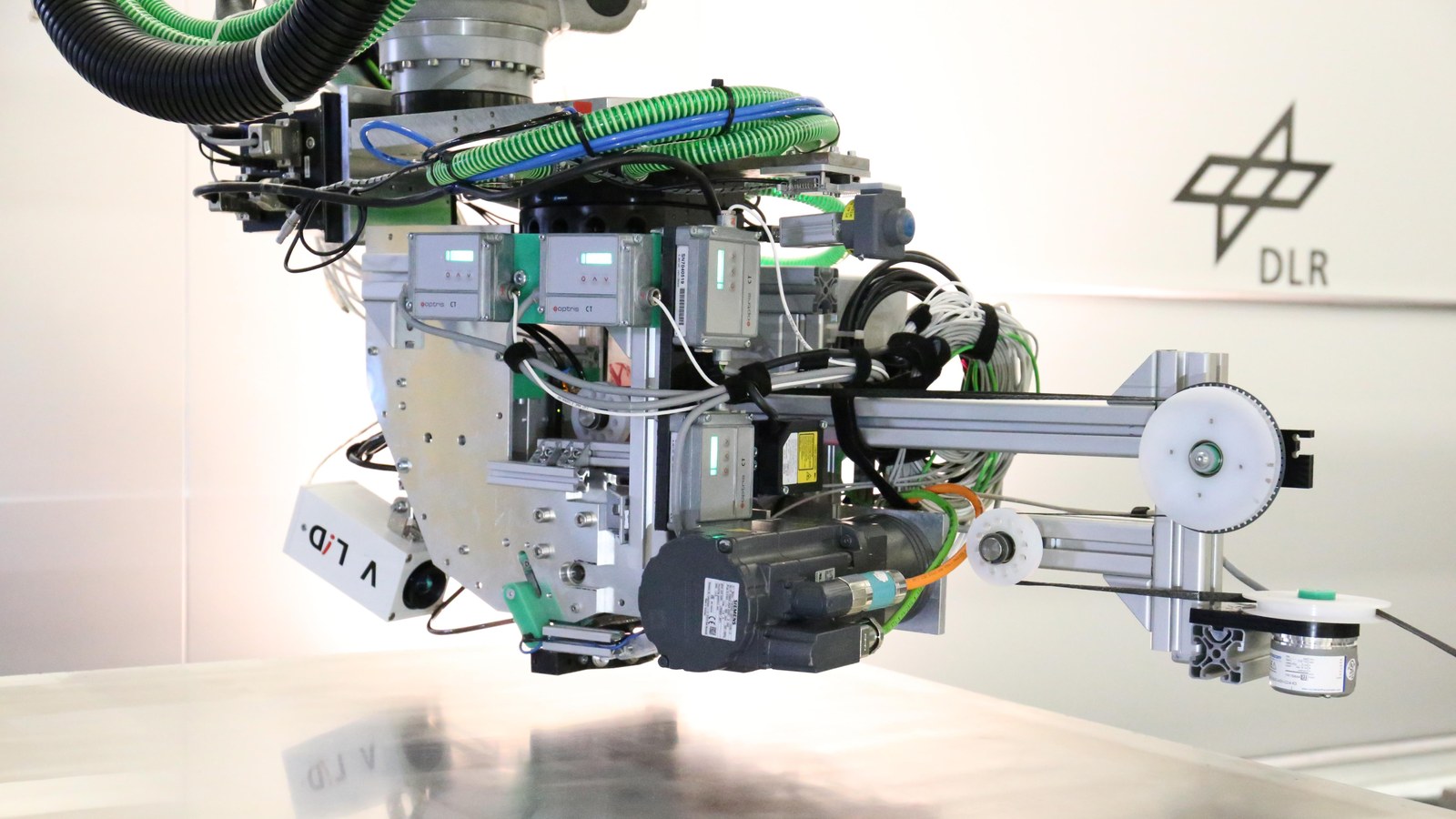

CoRe HeaT – a rapid heating method for carbon fibre placement

Continuous Resistance Heating Technology (CoRe HeaT) is an alternative heating method for placing carbon fibres. When electricity is conducted directly through the fibres, they are heated by their natural resistance. Common heating technologies using infrared heaters, gas or lasers have the disadvantage that they are either comparatively slow or very expensive. An outstanding feature of this new technology is the extremely rapid heating rates. Even the highest processing temperatures of up to 450 degrees Celsius are achieved in just a few microseconds, thereby allowing a much faster placement rate of two metres per second, even for pre-impregnated fibres. This technology is more cost-effective than conventional heating methods and also facilitates the design of extremely lightweight, compact devices for robotic fibre placement. The placement head developed at DLR Stade will make its public debut at the trade fair.

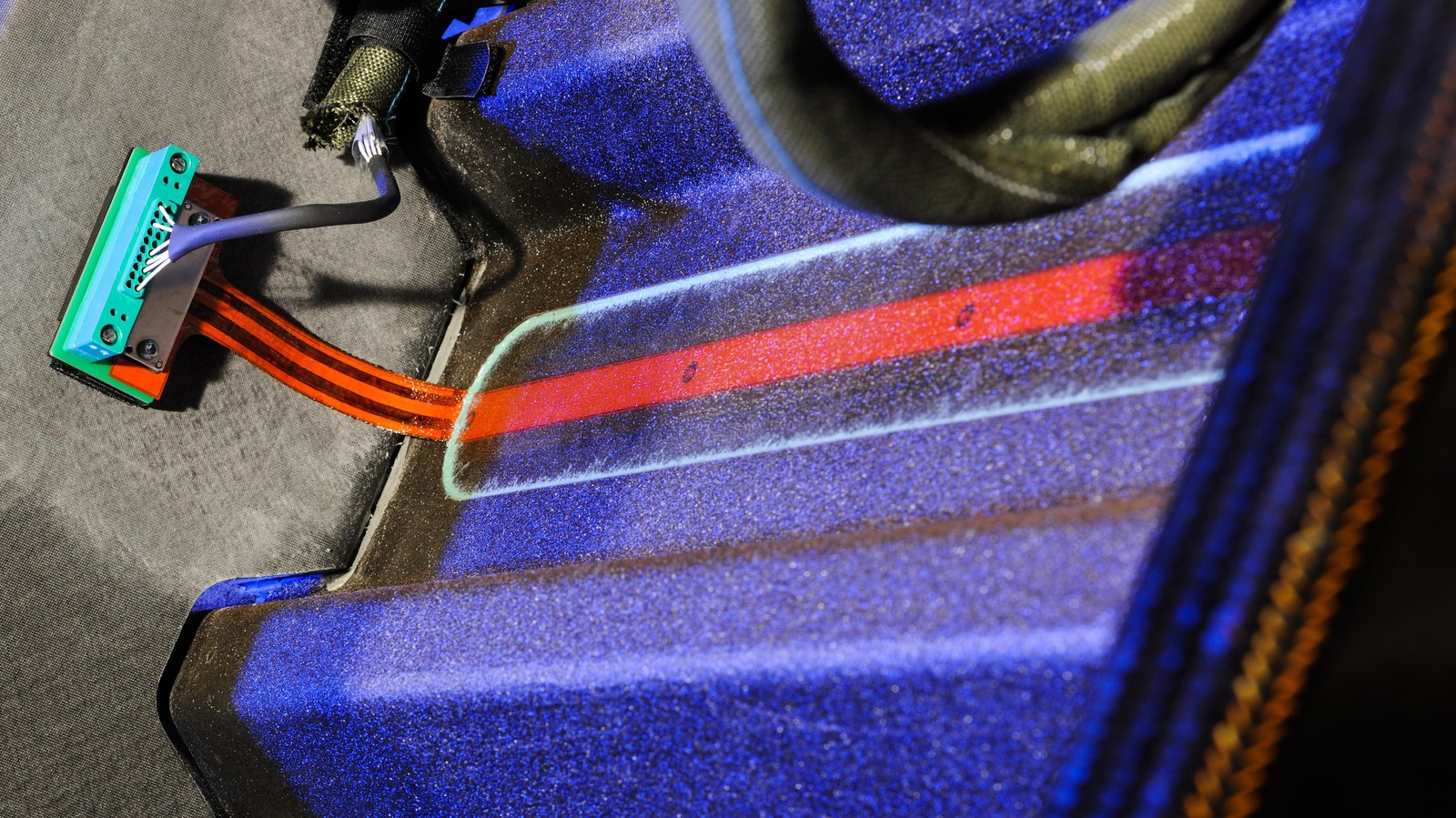

Structural Health Monitoring for damage detection

Carbon fibre reinforced polymer (CFRP) materials are increasingly used in aircraft. In order to make these aircraft even safer and easier to maintain, the DLR Institute of Composite Structures and Adaptive Systems is researching technologies that can provide information about the size and location of any damage. For Structural Health Monitoring (SHM), the CFRP component is fitted with sensors that function as a kind of nervous system. These sensors are not stuck on, but integrated directly into the material during the manufacturing process, thereby saving production costs. If an aircraft is damaged – as a result of being bumped during loading for example – there will be no need for a technician to attend to identify the defect. At the touch of a button, the structure will provide information as to where it has been damaged and whether a repair is required. Visitors to the DLR stand at the trade fair can interactively experience this SHM technology.