Protecting aircraft from ice – new heating system makes ice 'sweat'

- New electric de-icing technology using carbon fibres can efficiently melt ice on wing leading edges and prevent ice formation.

- Heating structure is manufactured as an integral part of the wing.

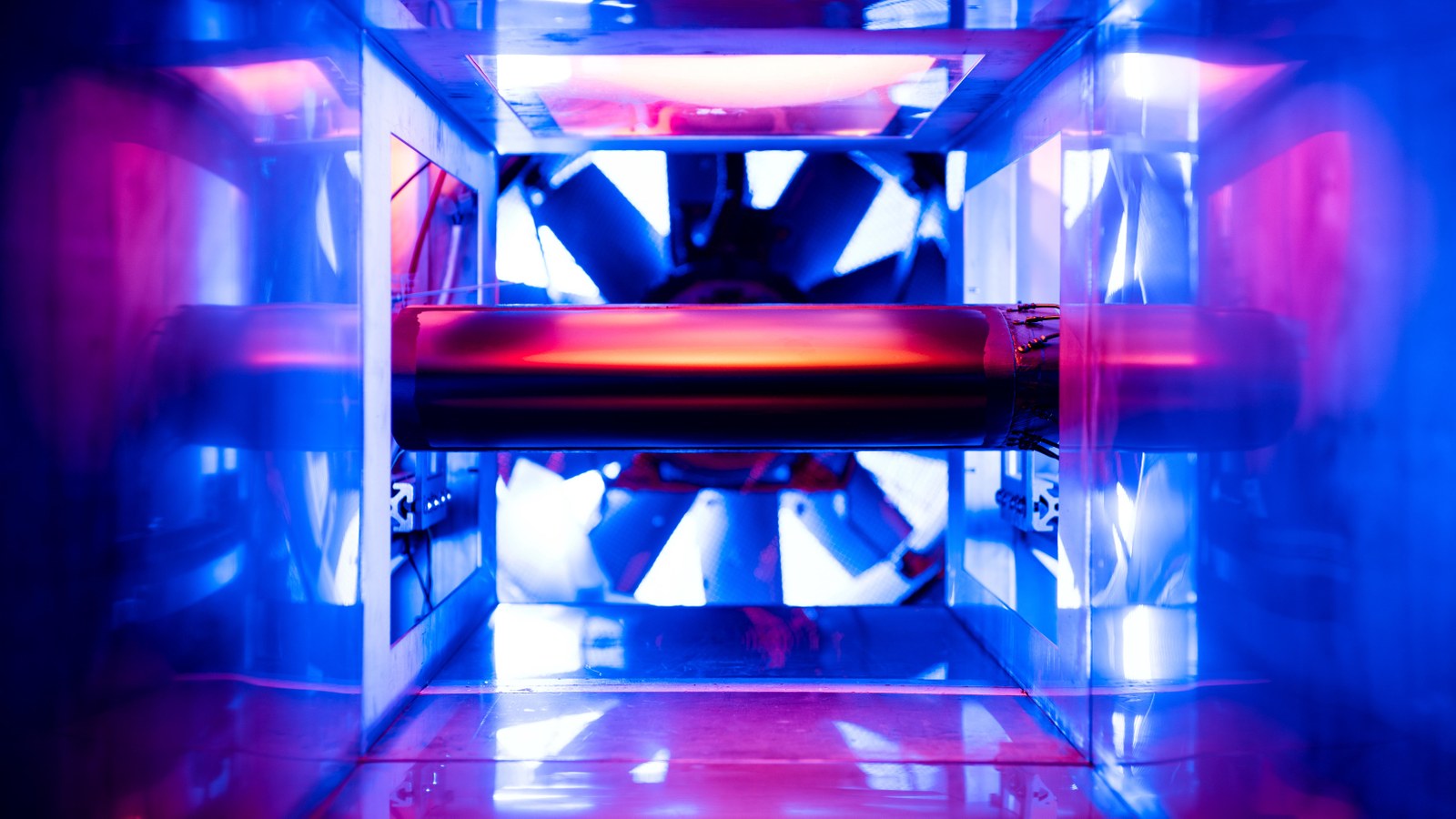

- Testing was conducted using the de-icing test bench at TU Braunschweig.

- Focus: Aeronautics, fibre-composite lightweight construction

Winter has arrived, and aircraft are suffering in the biting cold. As is the case with cars, ice can form on aircraft flight deck windows and flight instrument sensors. The wings are also among the critical points of aircraft, and icing can lead to significant aerodynamic penalties. The German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) has found a solution to this issue. A new electric de-icing technology using carbon fibres melts the ice efficiently and can even prevent its formation.

Integrated, load-bearing heating system

Future fuel-efficient, low-drag aircraft will fly using ultra-smooth wings with laminar flow. As even small accumulations of ice have a negative impact on the airflow around the wings and on energy efficiency, an innovative de-icing system is required. "In principle, this electrical resistance heating system is similar to window heaters in cars," explains Alexander Pototzky from the DLR Institute of Composite Structures and Adaptive Systems. "High-resistance electrical conductors are fitted to the wing structure; current is then applied, which causes them to heat up. In this case, the wing structure is made of carbon fibre reinforced polymer (CFRP), which is characterised by its low weight and high strength." The difference from current de-icing systems is that since the heating structure is also made of carbon fibres and is manufactured in one step forming an integral part of the leading edge of the wing, the heating system helps to transfer the loads acting on the leading edge. The heating structure is divided into individual heating zones, which can be controlled separately and thus ensure great flexibility for de-icing.

Tests on the de-icing test bed

The functionality and energy efficiency of the innovative heating system were investigated using the de-icing test bed at the Technischen Universität Braunschweig (TU BS). The TU BS de-icing test bed is a wind tunnel that is installed in a deep freeze chamber equipped with a water injection system. "This meant we were able to realistically re-create the conditions found during flight through a cloud, including the effects of incident flow, low temperature and droplets of moisture in the air," says Pototzky. Various heating strategies were used. The impinging water that immediately freezes can either be melted or evaporated by increasing the energy input. The strategy is referred to as anti-icing, as the formation of ice on the leading edge of the wing is prevented at all times. There is another strategy that saves energy and is known as de-icing, which permits the initial formation of ice on the wing’s leading edge, as long as it remains within certain limits. The ice is then melted during a periodic cycle. The tests validated the functionality of these heating methods and also enabled optimisation of the energy efficiency.