One-step manufacturing of a CFRP inter-stage

- First use of flashlamp heating to produce aerospace component

- Focus: Lightweight Production, Aerospace

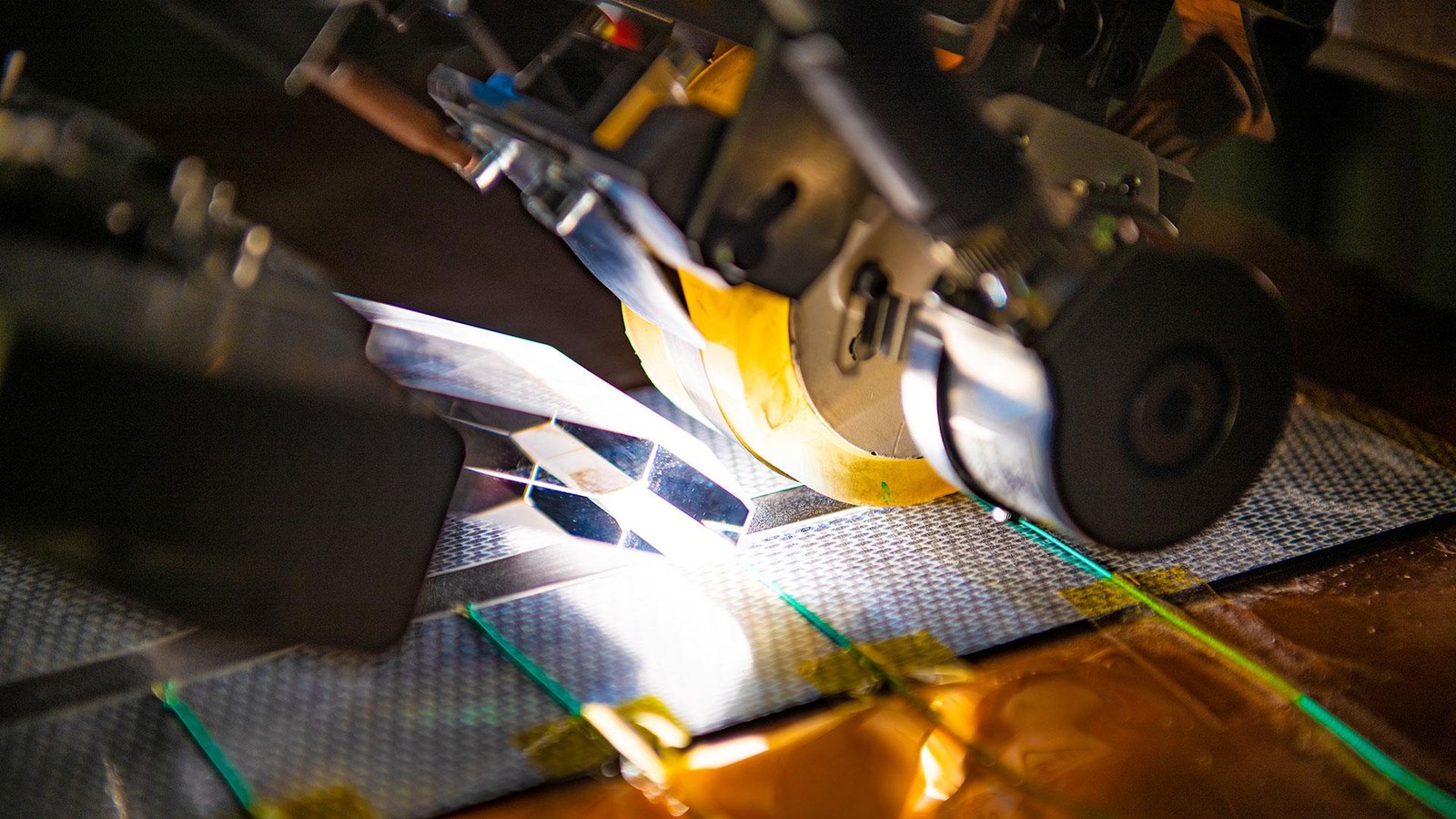

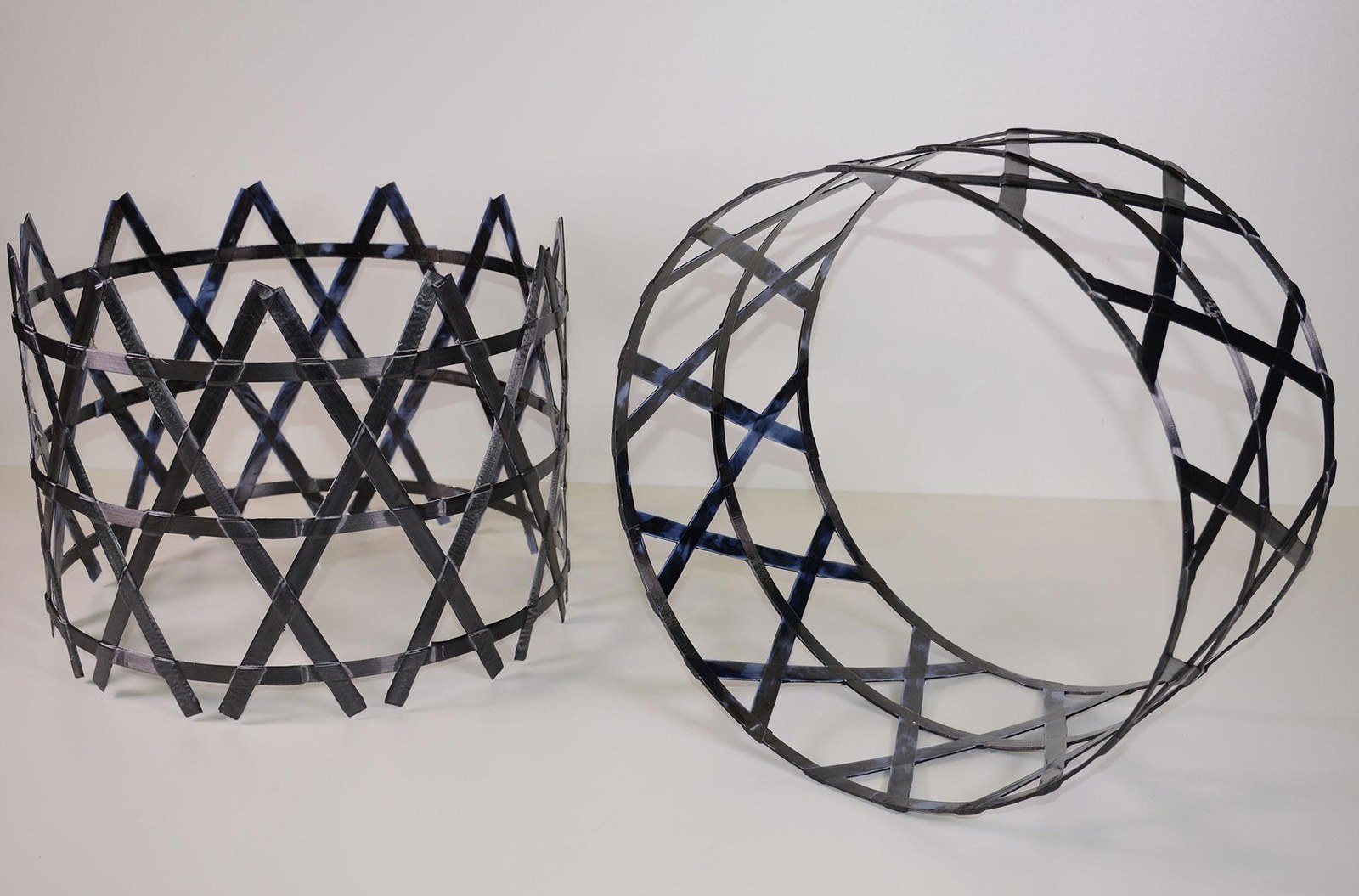

The DLR Center for Lightweight-Production-Technology (ZLP) in Augsburg manufactured a thermoplastic carbon fiber reinforced inter-stage structure for next generation European launcher systems. Using a cutting edge flashlamp heatsource the DLR developers manufactured two scaled demonstrator of a lattice inter-stage structure using in-situ Automated Fiber Placement (AFP). The process is currently under development at the DLR-Institute of Structures and Design. The goal is to saive weight and cost for future launchers. The demonstrators are the first aerospace components that have been produced using the flashlamp technology.

The unscaled part was designed to withstand typical loads during operation. Simulation results predict that it is capable to hold a load equivalent of 7180 times its own weight. The next step is the mechanical testing of the demonstrator. The results will be used to mature the technology. Within the DLR-project PROCOMP it will be used to demonstrate the one-stage production of a cryogenic tank structure made from thermoplastic carbon fiber reinforced polymer (CFRP) for a future launcher system. The DLR experts work in cooperation with MT Aerospace AG. The project is funded by the District Government of Upper Bavaria" as part of the "Bayerisches Luftfahrtforschungs- und Technologieprogramm" and will be running until the end of 2019.