DLR researchers measure the noise generated by the impingement of engine exhaust gases on landing flaps

- The noise that emanates from the interaction of engine exhaust gases and landing flaps is clearly audible.

- Wind tunnel measurements open up the possibility of predicting how large engines and wings can be configured so that they are more effective and quieter.

- Focus: Aeronautics, aerodynamics

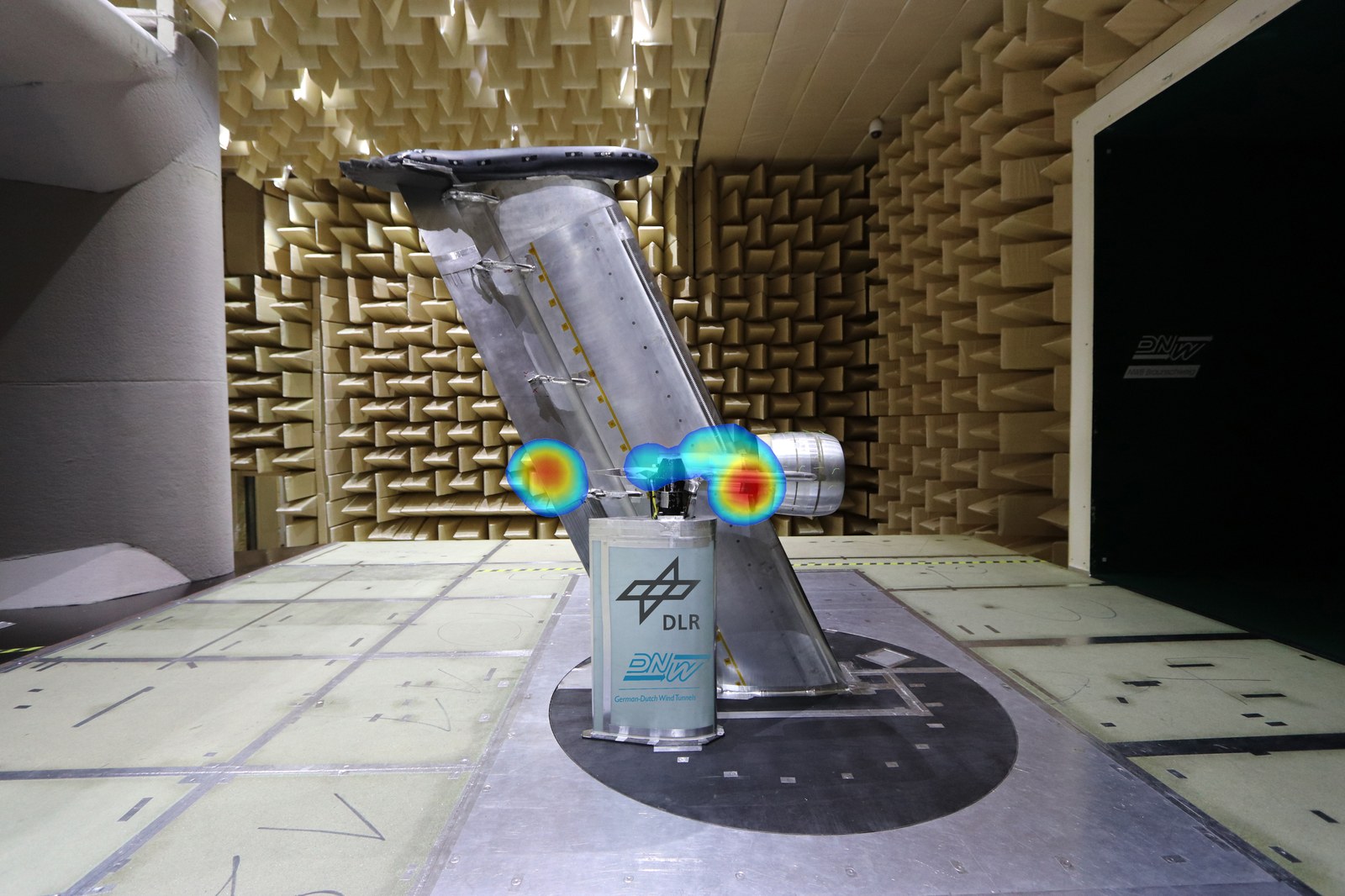

Engines and landing flaps are major sources of noise on any large aircraft. Using a special experimental setup, researchers at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) have now made it possible to measure the noise generated by the impingement of engine exhaust gases on the wing flaps. The engine exhaust was reproduced using a special engine simulator. DLR researchers tested the simulator in the measurement section of the Braunschweig low-speed wind tunnel. The simulator weighs approximately 40 kilograms and has a diameter of 30 centimetres and a power output of around 160 kilowatts. It is equipped with an oil pump, connections for computer data and a heating system. At 10,500 rotations per minute, with an exhaust velocity of 460 kilometres per hour and a visible condensation trail, it was used to simulate a landing approach during the test. In the test section, an aircraft wing was installed immediately behind the engine simulator. Coloured regions on the noise source maps clearly show that not only was the engine loud, but the landing flap of the DLR wind tunnel model was also emitting noise.

As the simulator – a Counter-Rotating Ultra-high-bypass Fan (CRUF) – started operating with cold compressed air at a pressure of 21 bar, the engine noise of around 60 decibels was distributed across the otherwise silent wind tunnel and was recorded by numerous microphones. At a realistic speed for a landing approach, the engine exhaust impinged on the extended wing flap, which projected directly behind the CRUF in the middle of the test section. The figures on the display immediately increased by several decibels – in the single-digit range, but with an increase in volume clearly audible to the ear. Even the increase to 63 decibels make it seem twice as loud in the wind tunnel.

Louder with interaction between exhaust flow and flap

"We have succeeded in acoustically measuring the interaction between the engine and the wing," says Fabian Lange of the DLR Institute of Aerodynamics and Flow Technology. The fact that such a significant difference was identified makes this is an interesting outcome for the researchers, and one that will be used in further research into exhaust / flap interactions. "Now, we can filter individual sound sources from the ‘overall noise’ of the engine and trailing edge and study them separately from one another," explains Lange.

This measurement result was made possible by the special test setup. With its large diameter and bypass ratio, the CRUF engine is a pioneering development given the trend towards ever larger and more powerful engines for modern passenger aircraft. For the first time, this kind of realistic engine is running in a wind tunnel – and in combination with a swept-wing model. This will allow researchers – after evaluating the results – to predict how larger engines will affect aerodynamics and acoustics, and thus how large propulsion systems and wings can be configured to make them quieter and more effective.

At the same time, the measurement results that are the culmination of a long series of studies as part of the interdisciplinary DLR project KonTeKst (Konfigurationen und Technologien für das emissions- und lärmarme Kurzstreckenflugzeug; configurations and technologies for low-emission and low-noise short-haul aircraft) are being used in the development of new acoustic simulators for engines. In a follow-on project, the researchers are planning to develop an acoustic simulator that will be operated electrically, rather than with compressed air. This will then be used to investigate a complete half model of an Airbus A320 in the wind tunnel. The ultimate goal and vision of the researchers is to be able to measure the acoustic and aerodynamic properties of the aircraft as a whole in the wind tunnel, rather than just individual components.