Mobility without particulates

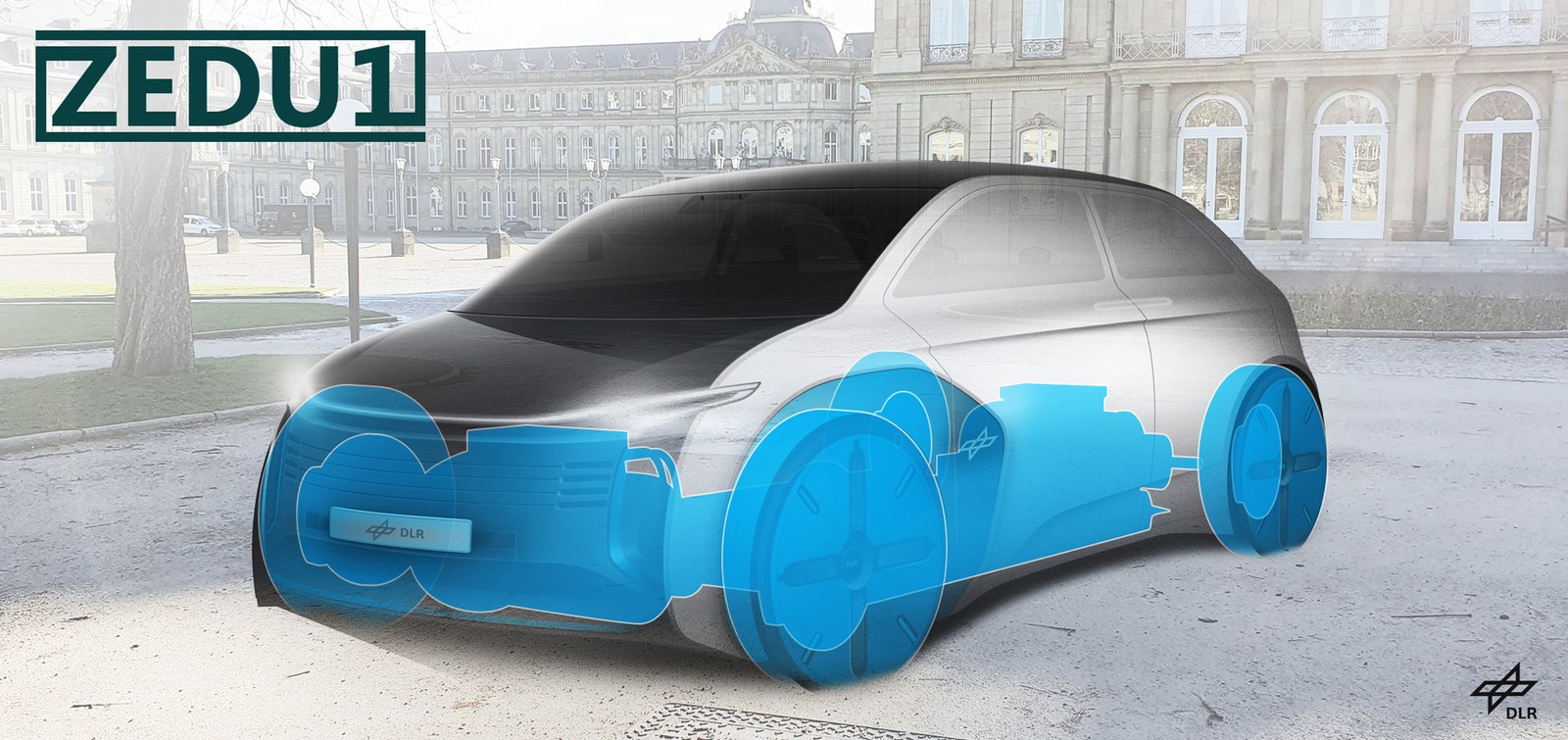

- The aim of the ZEDU-1 project is to develop an innovative vehicle concept. It is intended to avoid the emission of fine particulates and microplastics caused by brake and tyre abrasion.

- DLR is focusing on special braking systems and aerodynamically designed wheel arches.

- The components are being incorporated into a specially built test vehicle.

- During test drives on normal roads and on the DLR rolling road, the researchers will investigate how well the technologies work under real conditions.

- Focus: Transport

The environment is polluted not only by exhaust gases from internal combustion engines, but also by particulate matter. In the transport sector, particulate matter is produced during the combustion process and in the abrasion of tyres and brakes. The German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) is currently developing and testing an innovative vehicle concept as part of its Zero Emission Drive Unit – Generation 1 (ZEDU-1) project. The goal is to avoid particulate emissions as far as possible. When combined with energy from renewable sources and electric propulsion systems, this can make mobility almost entirely emission free. “We are concentrating on components that have received little attention in the past. The focus is on a particulate-free braking system and the collection and absorption of matter from tyre wear, so that this does not enter the environment,” says the project leader and DLR scientist Franz Philipps. The DLR Institute of Vehicle Concepts in Stuttgart, engineering company HWA and surface specialist Langlet are all working together on the project.

Project objectives – zero brake abrasion and negligible tyre wear

Abrasion of tyres on roads is responsible for more than a quarter of microplastic emissions worldwide. When it rains, these tiny particles make their way into the drainage system and thus into the water cycle. In Germany alone, this amounts to approximately 110,000 tonnes of matter a year. Braking also causes the abrasion of brake discs and brake pads. Over 90 percent of the resulting debris takes the form of ultrafine particles. These particles are considered to be particularly harmful to the environment and human health, as they can penetrate deep into our respiratory systems and become lodged there. "Given these figures, we have set ourselves some ambitious goals. We want to prevent brake abrasion altogether and reduce tyre abrasion by up to 90 percent," says Philipps. "It is important that our concept is highly effective and as compact, versatile and suitable for everyday use as we can make it. This will allow it to be applied directly to cars, commercial vehicles and even rail transport."

Completely rethinking braking systems and wheel arches

The project team is also forging new paths when it comes to the required technologies: "We are taking the brakes out of the wheel and integrating them into the drivetrain. This allows us to build everything in a very compact way. In conjunction with specially developed high-performance electronics, we are able to recover the braking energy almost completely," says Philipps. The team is also studying and combining different braking concepts. One of these is a special kind of disc brake, which works mechanically and acts as a closed system. The brake pads are kept in an oil bath. Brake abrasion takes place within the oil, which is constantly pumped through a filter and cleaned. Another approach is induction brakes, which are wear-free and use the force of magnetic fields to generate a braking effect. A newly designed wheel arch is intended to minimise tyre wear, with an aerodynamic shape that creates negative pressure while driving. Any wear thus occurs in a specific location. The resulting particles are absorbed by a filter system, similar to a vacuum cleaner.

In the test facility and on the road – practical trials with a research vehicle

Over the course of the project, the partners have set up the newly developed components to create demonstrators. Researchers have integrated these into a specially constructed test vehicle. They will then conduct test drives on normal roads and using the institute's rolling road to determine how well the new components are able to reduce fine particulate emissions under realistic conditions. For these tests, the researchers are working alongside the DLR Institute of Combustion Technology, also based in Stuttgart. This institute has state-of-the-art measurement technologies and a mobile measurement vehicle, which is able to detect and characterise particulate matter down to the ultrafine range. The analyses will focus on the total amount of particulate emissions and the size distribution of the particles.

The Baden-Württemberg Ministry for Economic Affairs, Labour and Housing has invested six million euros in the project.