Solar energy storage using sulphur

- Successful test of sulphur as a storage medium for renewable energy

- Solar-heated ceramic particles can achieve temperatures of up to 900 degrees Celsius

- Sulphur cycle can increase the efficiency of solar power plants

- Focus: Energy, solar research

Together with European research partners, the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) has developed a process that can generate electricity in a climate-neutral way using sulphur and solar energy. Initial tests with a pilot-scale plant have now been successfully completed.

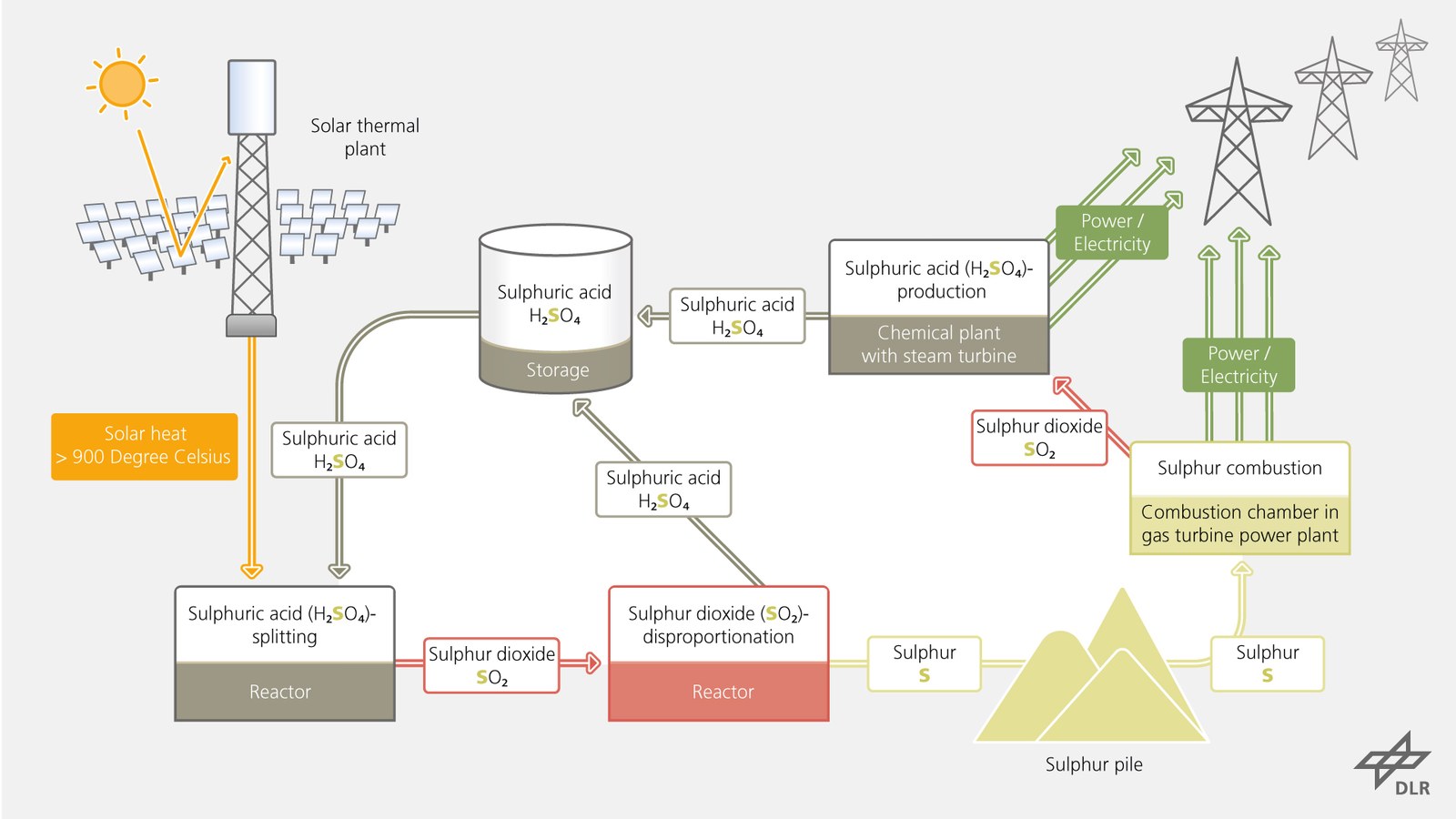

This process is based on a chemical cycle. It involves burning sulphur in special power plant turbines and converting the exhaust gases into sulphuric acid. Using solar energy, the sulphuric acid can then be converted back into pure sulphur, without producing carbon dioxide; this sulphur can then be reused as fuel.

Why sulphur?

Sulphur can be used as fuel for gas or steam turbines in power plants. In addition, sulphur is a promising energy storage medium for solar thermal power plants. Combining these two power plant technologies is a further step towards climate-neutral electricity production.

The energy density of sulphur is 30 times higher than that of molten salt, which is currently used in solar thermal power plants to absorb, transport and store solar energy as high-temperature heat. Because sulphur can be stored in powder or liquid form, it can easily be transported and stored over long periods of time.

Due to limited geological deposits and decreasing fossil fuel production volumes, it will become more economical in the future to sustainably integrate sulphur into processes that involve the recycling of their materials. In such cycles, sulphur can be repeatedly used as fuel. As demonstrated in the PEGASUS project, this can be achieved with the help of renewable energy sources.

Potential for power from renewable energy sources around the clock

A solar thermal plant can provide the high temperatures required for the decomposition of sulphuric acid using concentrated solar radiation. The resulting products, sulphur dioxide (SO2) and water (H2O), can then be reused to obtain sulphur in a process referred to as disproportionation. This can then either be stored or burnt in a gas turbine to generate electricity. The resulting gas is sulphur dioxide (SO2), which can be fed into a conventional sulphuric acid plant to produce sulphuric acid and large amounts of heat. This heat then drives a steam turbine that generates additional electricity. The cycle can then begin again with the decomposition of the sulphuric acid.

When strong solar radiation is available, a sulphur-based power plant can even produce more sulphur than is necessary for its daytime operations, thus enabling the plant to operate continuously. The resulting surplus of sulphuric acid can then be converted into sulphur by solar thermal means at a later stage.

Solar thermal plants with sulphur production can be operated effectively, especially in sunny regions. The sulphur produced can then be easily transported to regions with less sunlight.

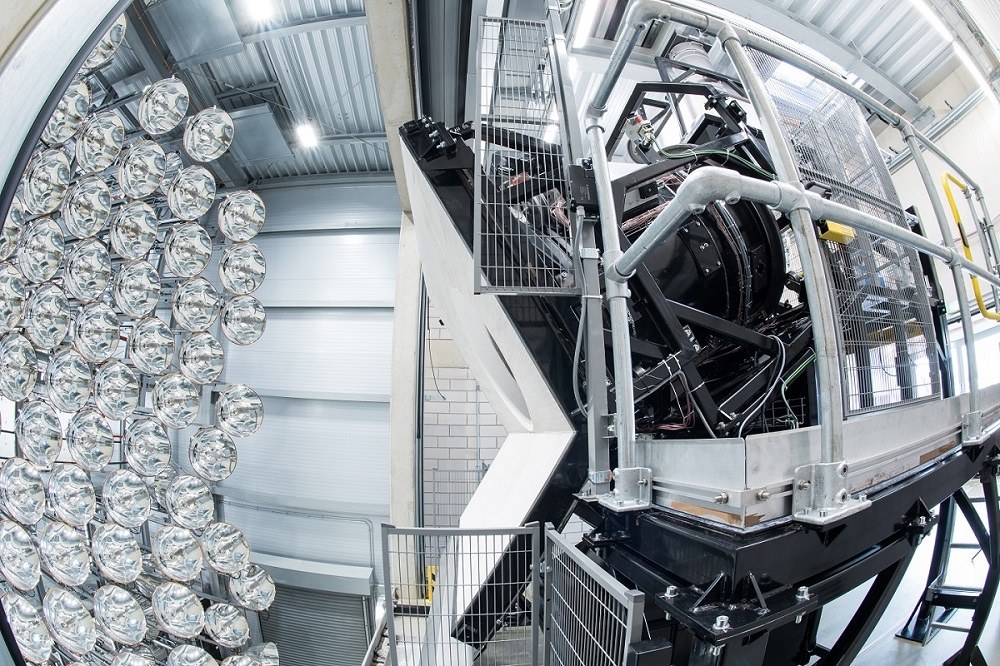

Pilot operation of the solar power plant using DLR's Synlight artificial Sun

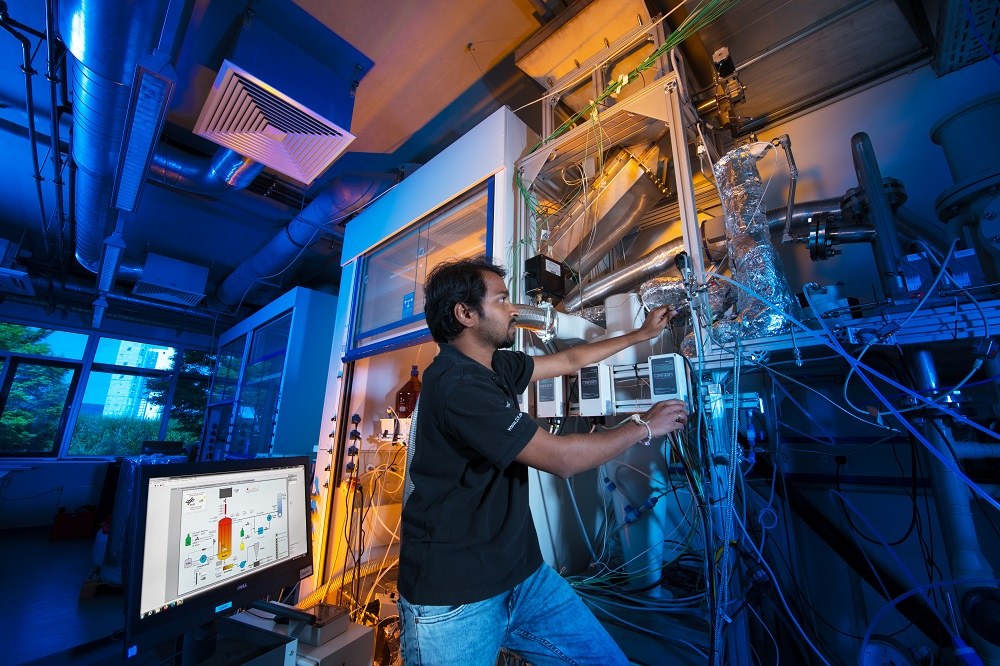

The aim of the PEGASUS project is to test the sub-processes of sulphuric acid decomposition using solar energy and the use of the resulting sulphur as a fuel in gas turbine power plants. To achieve the high temperatures required for the decomposition, the researchers combined a newly developed reactor to split sulphuric acid with a solar radiation receiver previously developed at DLR that uses ceramic particles as the heat transfer and storage medium.

In a particle receiver, small ceramic particles absorb and transport the incoming thermal energy to generate electricity and industrial process heat. Molten salt, currently used as a heat transfer medium in state-of-the-art solar power plants, can only be used at temperatures of up to approximately 550 degrees Celsius. Using heated ceramic particles, power plants can be operated at significantly higher process temperatures of over 900 degrees, resulting in higher efficiency and thus lowering the cost of energy production. For the demonstration, scientists from the DLR institutes of Future Fuels and of Solar Research installed a variant of the CentRec particle receiver developed for the Synlight artificial Sun in Jülich. At the same time, they investigated the sub-process of integrating sulphuric acid decomposition into the sulphur cycle in a laboratory.

Due to their high degree of innovation, the two sub-processes studied in PEGASUS placed high demands on the researchers. Solar-heated particles have never been used to split sulphuric acid before, for example. The combustion of sulphur at elevated pressure for use in gas turbines had also not been investigated before. Researchers at the DLR Institute of Future Fuels are working on the disproportionation reaction in the associated BaSiS project, funded by the German state of North Rhine-Westphalia.

Partners and funding

The Greek research institute APTL/CERTH supplied the catalyst materials for the sulphuric acid decomposition. The Karlsruhe Institute of Technology (KIT) developed the sulphur burner for the high pressures required. The Italian company NextChem was responsible for the process simulation and the technical and economic study. The Israeli company BrightSource designed the solar field, contributed to the process simulation and is the future end user.

The PEGASUS project received 4.7 million euros of funding from the European Commission's Horizon 2020 programme.