Interurban Vehicle – Green and comfortable travel even on long journeys

- DLR's Interurban Vehicle (IUV) will demonstrate how mid- and long-range vehicles may look in the future.

- Emission-free mobility, automation, safety and comfort are the main priorities.

- The IUV is a plug-in fuel cell hybrid, combining fuel cell, hydrogen tank and battery.

- The concept highlights how automation improves freedom in vehicle concept and architecture.

- Focus: transport, smart future mobility, hydrogen

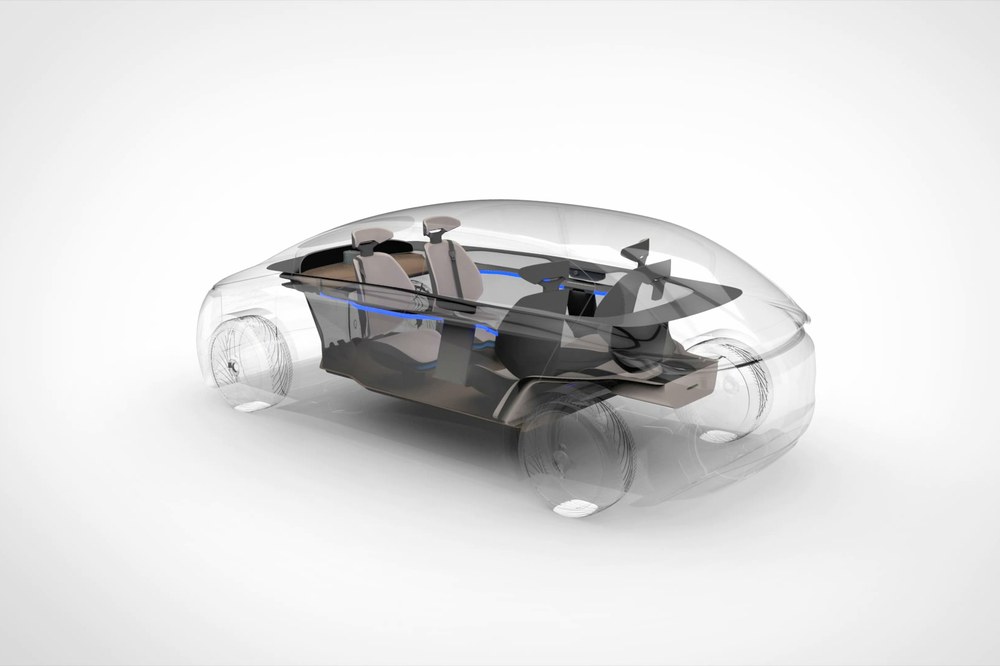

With the Interurban Vehicle (IUV), the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) has developed a ground-breaking concept for mid- and upper range vehicles, contributing to future mobility. At five metres long and two metres across, the IUV can accommodate five people. It combines a fuel cell and battery with new methods of energy management and is designed for emission-free and comfortable driving over long distances of up to 1000 kilometres. Autonomous features ease the strain on the driver and improve freedom when designing the vehicle interior. A clever combination of different lightweight construction methods keeps the tare weight of the IUV below 1600 kilograms, including the energy storage systems, while ensuring adherence to rigorous safety standards.

"This project involved us constructing a body demonstrator for use on the test stand. The demonstrator gives a first impression of how the vehicle may look in practice. It also facilitated the development of key components and technologies and enabled their measurement and investigation on the test stand. It reveals where there is room for improvement, and what can be achieved going forward with partners from industry and research," says project manager Sebastian Vohrer from the DLR Institute of Vehicle Concepts in Stuttgart.

Video: Interurban Vehicle – Moving forward sustainably

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

New construction methods, innovative materials and functional integration

Keeping power consumption low and the range high depends on a lightweight vehicle structure. "The IUV body structure weighs just 250 kilograms, about a quarter below what is otherwise common in this vehicle segment," says Vohrer. A variety of lightweight construction methods were applied to achieve this goal. Moreover, the IUV body consists to a large extent of fibre-reinforced polymers. Structures made of aluminium or sandwich materials are used in some areas as well – especially where components need to exhibit high rigidity and absorb considerable energy in the event of a crash. Among other things, the sandwich materials combine a top layer of fibre composite material with a lightweight core made from plastic foam or even sustainable materials such as balsa wood. This structure lends the body highly beneficial crash properties, while keeping the weight low.

The team built prototypes of selected components for the IUV and used them in crash tests to verify computer calculations and simulations obtained in upstream stages, among other things. These included the side skirt below the side doors, which is a particularly important structure and is intended to protect the occupants and the hydrogen tank in the vehicle floor in the event of lateral impact. After all, the IUV does not have a centre pillar, which in conventional car bodies would connect the floor and roof of the vehicle and act as a crash element. Eliminating the centre pillar also creates large spaces for the doors that, when combined with sliding doors that open in opposite directions, make entry and exit particularly easy.

Wherever possible, DLR also applied the principles of functional integration – another lightweight construction approach. "The structures fulfil several functions here. The floor structure, for instance, is used to conduct electricity and transmit data, in addition to carrying all the vehicle superstructures. This eliminates the need for additional cable lines and further reduces the overall weight," Vohrer explains.

Emission-free travel: fuel cell, battery and smart energy management

The IUV is designed as a plug-in fuel cell hybrid. It combines a fuel cell with an output of 45 kilowatts, a 700-bar hydrogen pressure tank and a battery with a capacity of 48 kilowatt hours. This configuration gives the IUV a total range of up to 1000 kilometres. With an aggregate output of 136 kilowatts, the electric motors accelerate the vehicle up to 180 kilometres per hour. The refuelling process at a hydrogen filling station takes approximately the same time as for conventional drive systems. The battery can also be charged separately. The fuel cell is located at the front of the car, while the battery is fitted to the rear of the five-metre-long vehicle. The hydrogen tank is installed in the underbody and holds approximately 7.5 kilograms of hydrogen.

The DLR team from the Institute of Vehicle Concepts also addressed the issue of energy management. Increasing the degree of vehicle electrification requires optimising the efficiency of all electrical, heating and cooling processes, as there is otherwise a risk that range or comfort features such as air conditioning or information and entertainment systems may suffer. One of the technologies examined more closely during the development of the IUV is metal hydride storage systems. This new type of storage system is being investigated and developed in close cooperation with the DLR Institute of Engineering Thermodynamics. These systems can use some of the pressure difference between the hydrogen tank at 700 bar and the fuel cell at five bar to generate additional cooling for the on-board air conditioning and to support the conventional cooling unit.

Autonomous driving improves flexibility and occupant comfort

DLR researchers working on the IUV also investigated how autonomous driving would affect the vehicle concept and architecture. To do this, they assumed a high level of automation (SAE Level 4), in which the car is completely in charge of driving duties and only instructs the human to take over when it can no longer cope with a task. "Automation can ease a lot of the strain on drivers, especially on long journeys. It allows us to make the interior of the vehicle more open and flexible at the same time," says Vohrer. The IUV team developed a variety of designs for this purpose and conducted evaluations to determine their functional and technical feasibility. Among the outcomes is the IUV seating configuration with rotating front seats to enable variable adaptation to the driving mode. Occupants can sit with their backs to the direction of travel in autonomous mode, eliminating the strict separation between the two rows of seats and creating a shared space for communication. The bespoke air-conditioning concept in the IUV adapts to the interior and current occupants. No longer equipped with central dashboard controls, each passenger can adjust the air conditioning individually using overhead interfaces in a similar manner to aeroplanes.

The DLR Next Generation Car project

Twenty DLR institutes are working together to develop technologies for viable, futuristic road vehicles within the large-scale Next Generation Car (NGC) project. In addition to the IUV itself, two other vehicle concepts address the needs of urbanisation: the Urban Modular Vehicle (UMV) is a modular city car for personal and commercial use, while the Safe Light Regional Vehicle (SLRV) is designed for commuting, car sharing and as a shuttle car.