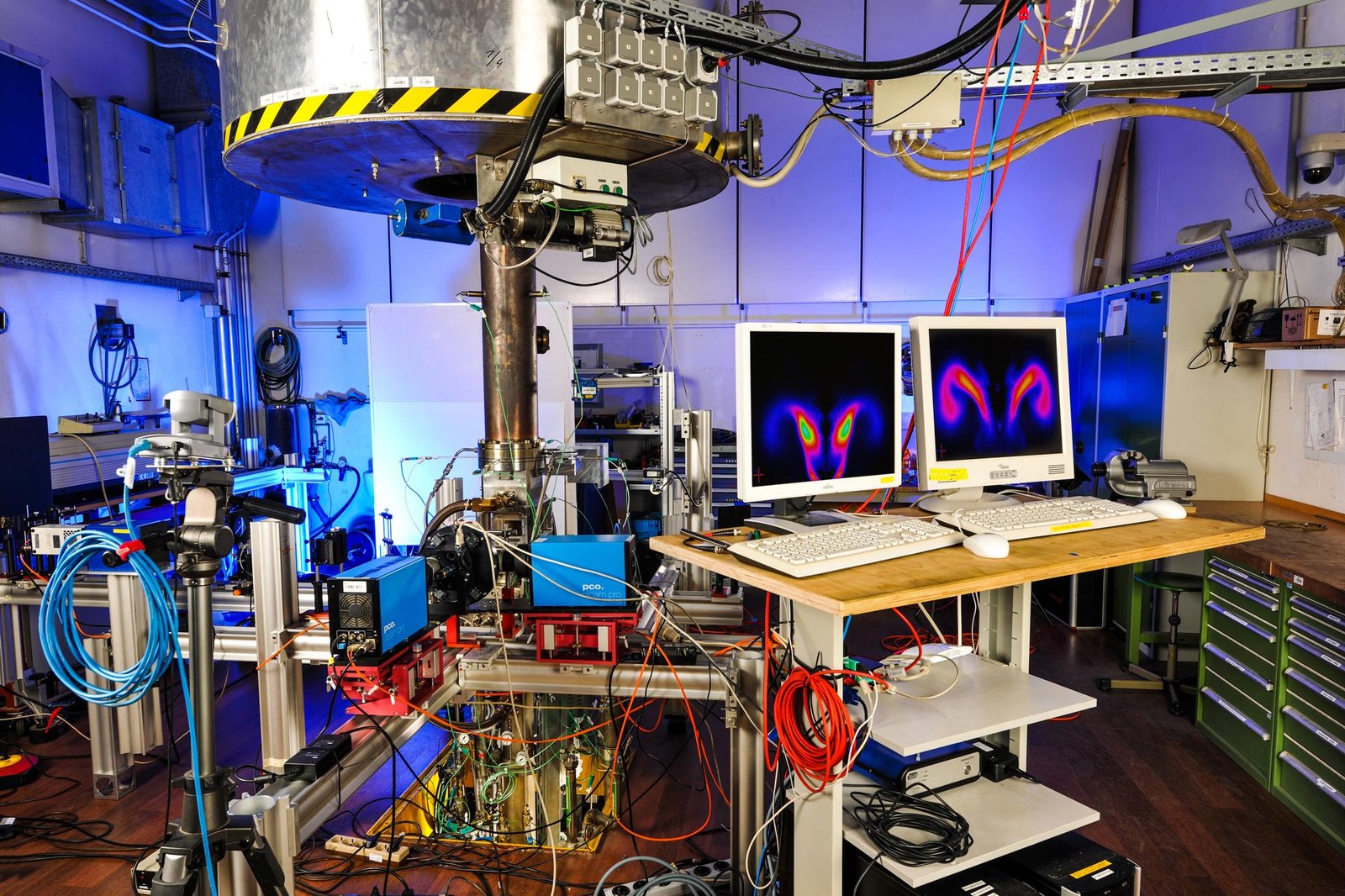

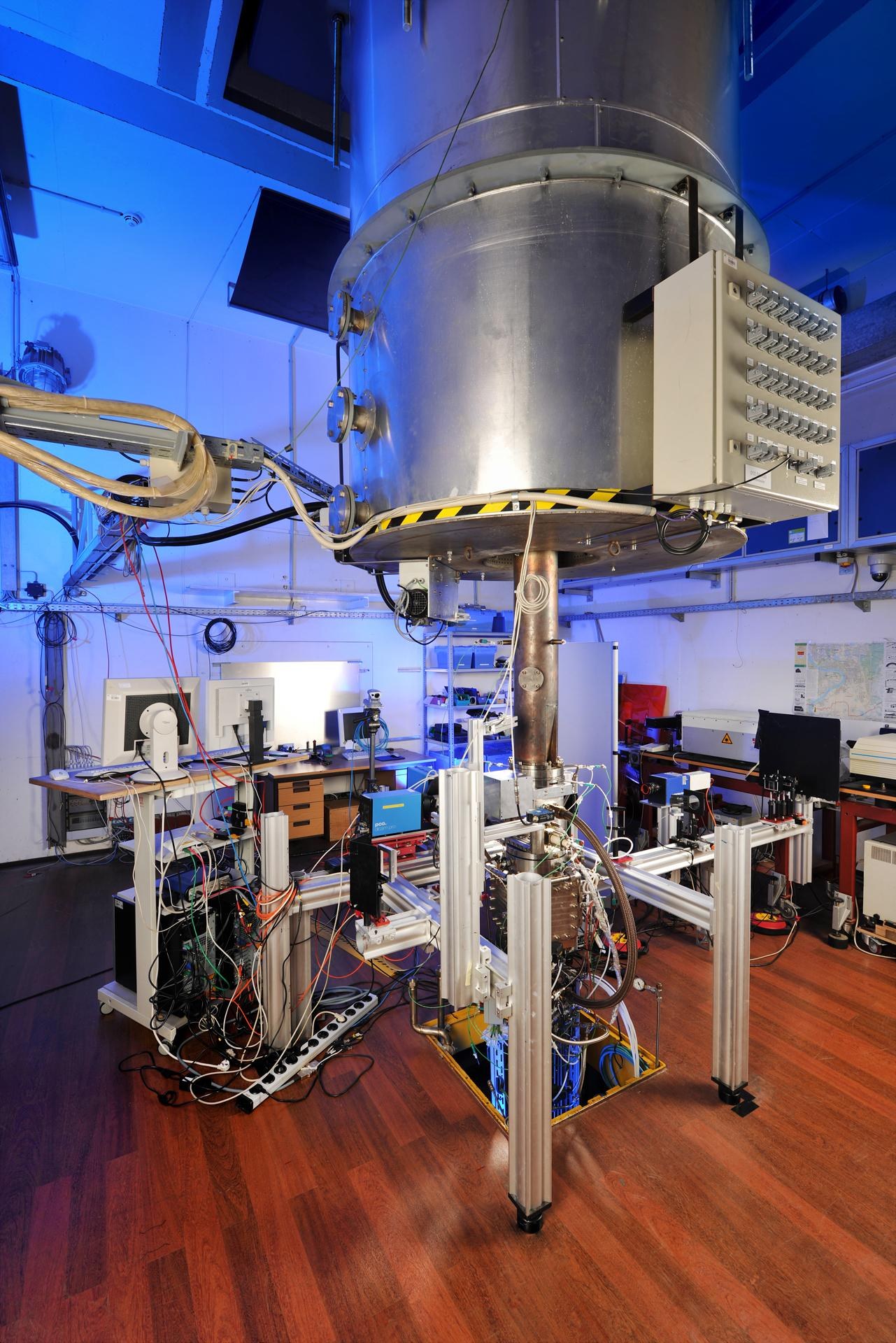

Single Sector Combustor (SSC)

Burners and combustor elements for advanced aircraft engines can be tested at the Institute of Propulsion Technology in Cologne. The investigations use advanced optical measurement techniques to focus on the reacting two-phase flow field.

Realistic capture of combustion process data

Researchers at this German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) large-scale facility are particularly interested in the flow fields, reaction zones, temperatures, combustion instabilities and soot-formation mechanisms. Research conducted here aims to record combustion processes in a realistic environment. The facility provides a unique setting for the development of aircraft burners and combustion chambers, as well as for the development and application of laser-optical measurement techniques.

In addition to accommodating a broad range of fuels (liquid or pre-evaporated kerosene, alternative liquid fuels, natural gas), the SSC can also be run under the operating conditions of an aircraft gas turbine with regard to air pressure and inlet temperature. At the same time, the combustion chamber provides unobstructed optical access to the primary zone from three sides. The combustion chamber walls on the fourth side can also be adapted for laser-optical investigations.

Many years of experience in the design, production and operation of high-temperature components created using additive manufacturing enables the use of measurement sections that are created using Selective Laser Melting (SLM). From a metrological perspective, the large-scale facility is an indispensable link between atmospheric laboratory burners and demonstrator combustion chambers such as High Pressure Test Rig 1 (HBK1), which feature full-scale production or development burners. The ability to perform highly precise movement of the combustion chamber along three spatial axes enables the use of static measuring equipment.

Especially for the development and testing of new, often combined measurement techniques, this enables the uncomplicated setup of the large facility. This is an extraordinary advantage and a unique capability with regard to the approximation of realistic conditions in the measurement section.