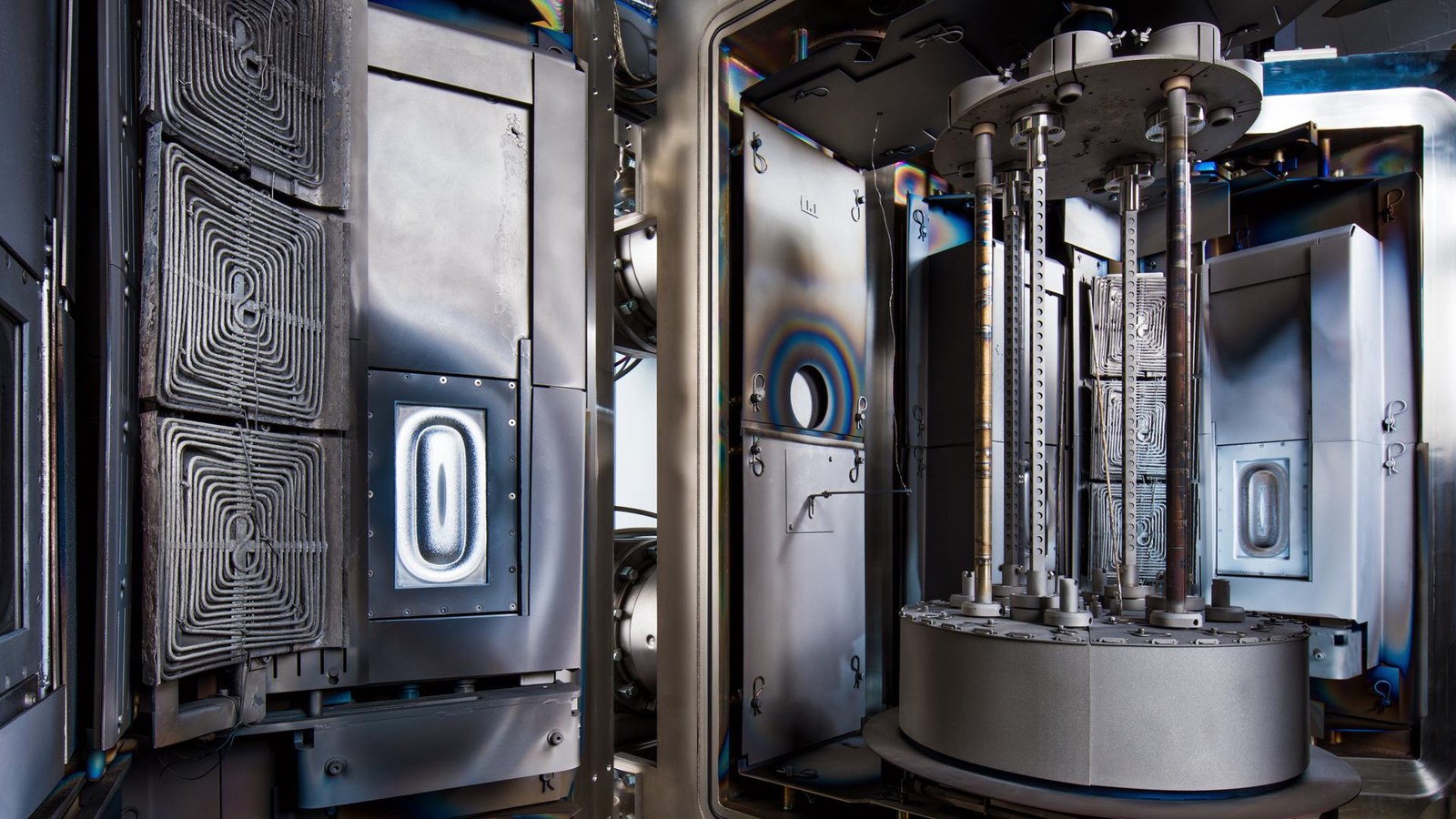

Vario-PVD

This large-scale facility at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) DLR Institute of Materials Research in Cologne is used to produce different coatings to protect almost all of the solid materials required for aeronautics applications, such as in turbines.

Protective coatings for projects in all fields of research

Vario-PVD (physical vapour deposition) allows a wide variety of coatings to be developed to protect almost all of the materials that are used for aeronautics applications. In addition, it enables the research and development of functional coatings with a highly variable composition and layer structure for applications in all DLR fields of research. It can be used for both basic development tasks and for near-series prototype research.

This large-scale facility is used to produce coatings by two basic variants of the PVD technique – magnetron sputtering and electron beam vapour deposition. These technique variants can be used to coat samples for development tasks and lifespan tests, as well as real components, with typical dimensions, such as those commonly found in aircraft turbines.

DLR's Vario-PVD facility enables the development of a wide range of protective and functional coatings with significantly improved properties for aeronautics, space, energy and transport applications. The system can be used to create metallic and ceramic coatings in monolithic, graded or multi-layered arrangements, ranging in thickness from a few nanometres to several hundred micrometres.

These coatings increase the lifespan of components or make it possible to use them reliably in the first place. The flexibility of PVD processes and parameters also allows for the introduction of new features such as sensors or thin-film format energy storage.