Step 3: Transverse stiffening

Step 3: Transverse stiffening

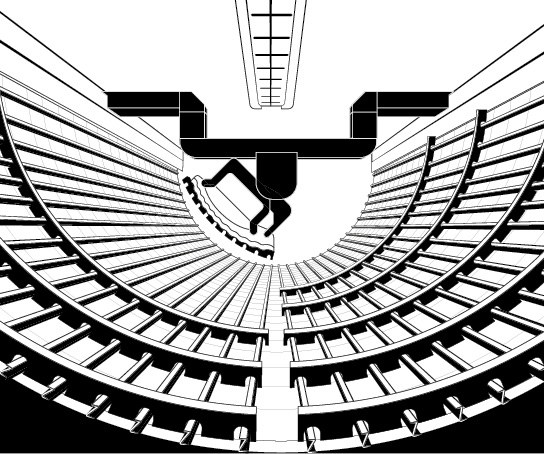

Twenty-four press-formed frames are resistance-welded on the installation tool using a motor-driven bridge developed by DLR. First, a robot precisely positions the frames at the target position. Next, a welding element between the components – in this case the frame base and the fuselage skin – is heated to 380 degrees Celsius and cooled under pressure. Little by little, 14 bases per frame are added to the skin. This robust technology delivers the joining strengths required by the aviation industry.

Credit: DLR (CC BY-NC-ND 3.0)