Safety first

DLR is developing technologies for aeronautics, space, energy and transport and is actively engaged in security and defence research. It is concerned with protecting space infrastructure, detecting damage to aircraft and providing disaster relief – and this is just the tip of the iceberg.

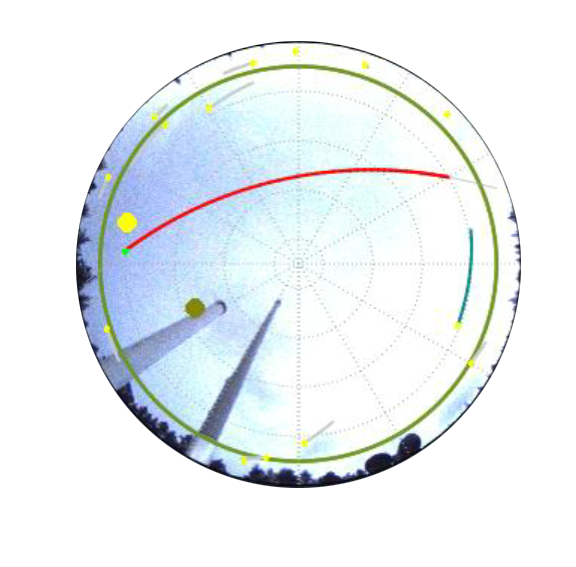

Alexander Köhler looks at his monitor. Curved lines – yellow, green, orange and red – snake across the screen, some more jagged or tall than others. "The red lines are the Galileo satellites," Köhler explains. He is inside the mobile container of the LaBoT laser ground station, surrounded by monitors displaying rows of numbers and camera images alongside these colourful lines. Each one represents a satellite rising above the horizon. LaBoT has its eye on the entire sky, and on this particular afternoon has detected more than 30 satellites. The dome next to the container houses a reflector telescope used to track the satellites and receive or transmit data. Laser communication with satellites under real-world conditions is a key research focus at the Responsive Space Cluster Competence Center (RSC³) – the centre of excellence for rapid satellite deployment at DLR's site in Trauen.

The goal of RSC³ is to set up the technological basis for future space infrastructures to make them more resilient to failure.

The global navigation satellite system Galileo is being used in traffic management, fleet logistics, agriculture, industry, the energy sector and by public authorities. Köhler opens the dome of the LaBoT at the click of a mouse, two hatches slide open on either side and the telescope aligns itself. Everything else is invisible. The laser operates in the near-infrared range, beyond human sight.

The RSC³-operated LaBoT is part of a Europe-wide network of laser ground stations. This network is dedicated to exploring future, resilient, optical communications technologies. For DLR's national competence centre, the main focus is on security, crisis management and the protection of critical infrastructure in space.

Speaking of Trauen … where exactly is this? The small town in the Lüneburg Heath lies between Hamburg and Hanover. It belongs to Faßberg, where the German Air Force and Army Aviation Corps are based. The area is rural, with no major towns nearby. Who would want to work here? One look at the site and it's easy to understand why you often hear 'high-tech on the heath' in the area. Andreas Ohndorf, head of RSC³, says "Within three years, we have been able to recruit 30 employees, and plan to take on a further 20 to 30 in the coming years."

Security and defence research at DLR

DLR is dedicated to research and technology development in the fields of aeronautics, space, energy, transport, civil security and defence. Current projects include air defence research, tracking and positioning of orbital objects, advancements in small satellite capabilities, the development of high altitude platforms, helicopter operations for maritime emergency preparedness, hazardous materials detection and the use of quantum sensors in maritime reconnaissance. Key focus areas include maritime security, defence research, civil security and dual use applications. Notably, 29 of DLR's 54 institutes and facilities are actively involved in security research.

Into space in three days

"The goal of RSC³ is to set up the technological basis for future space infrastructures to make them more resilient to failure," says Ohndorf. Resilience encompasses multiple aspects, including stress resistance, the ability to defend against threats, rapid deployability and sustainability. Space systems are regarded as critical infrastructure and must therefore be protected, whether for civilian or military purposes – a consideration that also plays a role at RSC³. "We anticipate future innovative and disruptive technologies and develop solutions for peace, crises and national and collective defence," adds Wolfgang Jung, Head of Technology at the RSC³.

If necessary, you can bring electricity and water with you. This allows the system to function entirely independently of local infrastructure.

Rocket launch from any location

Just a few steps from LaBoT sits an unassuming standard shipping container, easily loaded onto lorries, ships or trains. It appears ordinary from the outside, marked only by the 'MoHyPer' lettering alongside the DLR and RSC³ logos. MoHyPer, which stands for 'Mobile Hydrogen Peroxide Transport and Storage Container', was developed at RSC³. The container's interior is lined with gleaming stainless steel, housing various cylinders, pipes and regulators. It has the capacity to store 1100 litres of highly concentrated hydrogen peroxide, a fuel used in rocket and satellite propulsion. The container only needs a power and water connection regardless of where it is located. However, as Nora Riedel, a scientist working on MoHyPer, explains, "If necessary, you can bring electricity and water with you. This allows the system to function entirely independently of local infrastructure." The container can easily be used to refuel a rocket upper stage, which might, for instance, carry a small satellite into orbit. Small satellites typically weigh up to 500 kilograms, with some being no larger than a shoebox. Riedel is currently completing her doctoral thesis at the DLR site in Trauen, focusing on the decomposition of hydrogen peroxide.

One of the projects led by RSC³ is REACTS (Responsive European Architecture for Space), a collaboration including 39 European institutions and companies from 13 countries. Their aim is to establish a responsive architecture capable of placing satellites into low Earth orbit (LEO) within 72 hours. This would help fill gaps, such as those resulting from satellite communication failures. Accomplishing this within just three days is a considerable challenge, as satellite missions are typically planned over months or even years.

Environmental testing for satellites

The Responsive Space Technology Evaluation Center (RSTEC) is tucked away in a grey, prefabricated building and forms part of the RSC³ space segment. Here, nano (and micro) satellites are assembled, integrated and rigorously tested to ensure they can endure the rigours of launch and operate effectively in space. Before entering the cleanroom laboratory, Hannes Brandt changes into a gown, trousers, hood, gloves and shoes. He takes care to prevent any dust from interfering as he secures a satellite onto the attitude control stand. This apparatus, with three axes of rotation, assesses the satellite's ability to orientate itself in orbit. Brandt can activate a magnetic field or artificial sunlight and simulate various attitudes.

In another cleanroom, researchers examine the satellites' ability to withstand temperature fluctuations and vacuum conditions. Under what conditions and for how long can satellites be kept ready for launch? To answer this question, RSTEC employs the bell-shaped transport and storage container, TULBE. "If a satellite is to be operational in space within a few days, it must already be stored at the launch site with its operating components and propulsion system so that it can be reactivated quickly," says Wolfgang Jung. "There is no time for planning, assembly or testing once the satellite is needed."

RSTEC's capabilities are utilised not only by DLR but also by other research institutes and by industry. According to Jung, internal and external networking and cooperation are essential to the success of RSC³. "By working together, we are making a vital technological contribution to increasing the security and resilience of future space infrastructure." LaBoT, MoHyPer and RSTEC received support from the European Regional Development Fund (ERDF) of the state of Lower Saxony.

Safety in aviation

About 100 kilometres to the south of Trauen, we shift from space to aviation – but here, too, the emphasis is on safety. In the foyer of the DLR Institute of Lightweight Systems in Braunschweig, various items are on display, including a circular tank, different protective helmets, a section of a passenger aircraft and the AirBrake, a brake flap from a fighter aircraft. "We are demonstrating what can be achieved with composite materials," says Robert Kaps. All the products on display have a distinctive black pattern: tiny bundles of up to 24,000 filaments – essentially the finest carbon fibres – are woven or deposited individually, impregnated with resin, heated and hardened. "Our institute develops and tests new lightweight construction technologies that conserve resources and facilitate climate-friendly solutions," Kaps adds.

DLR/ZKI

Air brakes are typically made of metal and are used to reduce an aircraft's speed when deployed. "The structure has to withstand high loads. This can be achieved thanks to the special features of composite materials, which can also simplify production and reduce costs by integrating functions and reducing the number of components," says Kaps. The scientists have designed two shell elements for the AirBrake and bonded them together. A great deal of development work was necessary to improve, test and further optimise the elements. There are more than 30 sensors in the underside and the load introduction fittings (brackets) for monitoring structural integrity. These elements, which are reminiscent of a skeleton, distribute the load in the flap against the wind pressure when it is opened. "There are many new challenges in aircraft construction right now," says Kaps. "With its expertise, DLR can make a significant contribution to developing solutions to these challenges."

Protecting technology together

Anke Kaysser-Pyzalla, Chair of the DLR Executive Board, gives an insight into security and defence research at DLR.

Ms Kaysser-Pyzalla, how important is security and defence research at DLR?

Civil security and defence research is a key focus for DLR, in keeping with our social mandate. Geopolitical developments since 2014 have ushered in a unique and far-reaching turning point for Europe. Our expertise and command of key technologies allows us to make a crucial contribution towards protecting society and its infrastructures. Our research into civil security and defence is institutionally funded by the Federal Ministry for Economic Affairs and Climate Action (BMWK) and the Federal Ministry of Defence (BMVg). We also secure additional funding through special financing measures and partnerships with authorities, public institutions, organisations and industry. Our office in Brussels has also enabled us to obtain funding from the European Defence Fund.

How long has DLR been involved in security and defence research?

Security and defence research has been part of DLR for more than 30 years. However, for a long time, it remained relatively out of the public eye, and to be frank, there wasn't much public interest in it either. Nevertheless, now, as in the past, we continue to conduct research and cooperate in the interest of Germany's security and that of its allies.

What does DLR bring to the table?

By combining our expertise in aeronautics and space with our competencies in energy, transport and digitalisation, we can fully develop the potential for security and defence research at DLR. First, an example from civil security research: during the floods in Germany in early summer this year, we conducted aerial surveys of the disaster areas in Bavaria, creating real-time situational images. These can be used by rescue workers to identify passable routes, among other things. When it comes to maritime security, we are conducting research into the protection of ports. In the space sector, our focus extends to the protection of critical infrastructure, particularly the security of satellites.

What forms does cooperation take?

DLR's role is to provide support, advice, expertise and technologies to enhance Germany's security. This involves driving innovation and development forward and quickly translating this into practical applications and capabilities. Our daily business includes joint exercises with authorities, police and fire departments, as well as strategic collaborations with organisations like the World Food Programme (WFP) and the German Federal Police. DLR employees also perform their reserve service at various locations and contribute their expertise. We also engage in joint projects, such as with I.S.A.R. (International Search and Rescue) Germany. With our drones, we assist in mapping disaster areas, providing crucial support to rescue teams. We are in a position to provide reliable and resilient expertise for collaborations across the entire spectrum of DLR's capabilities. DLR fulfils its societal responsibilities through the intensive exchange of knowledge with authorities such as the WFP, the German Federal Agency for Technical Relief (THW) and public stakeholders, as well as targeted technology transfer with industry. However, achieving this requires us to think About security and defence research in collaboration with industry, government and academia. This includes implementing measures to jointly protect our knowledge and technologies.

The digital twin, always at hand

The AirBrake is also used to demonstrate aircraft maintenance methods. When an object strikes an aircraft's outer skin, the extent of the damage is not always immediately apparent. Consequently, the aircraft is often grounded as a precaution while experts conduct an on-site inspection. This process can be time-consuming, especially if the experts are located far away. Georgia Albuquerque from the DLR Institute of Software Technology and Robert Kaps put on augmented reality (AR) headwear. With these, they can see not only the physical AirBrake but also ist digital twin and various analytical tools. "The component is fully documented via a digital twin. We can view the current damage as well as all previous damage, and perform an assessment," explains Georgia Albuquerque. Only one of the two needs to be physically present next to the AirBrake. A third person, for example an expert from the manufacturer, can join in remotely using another pair of AR glasses to see the same view. Coloured areas – green, yellow or red – provide immediate information for damage assessment. The application study has yielded promising results and can also help to streamline logistics in the event of an incident or damage.

Rapid assistance in the event of a disaster

From Braunschweig, we head south again to Oberpfaffenhofen, home to the Center for Satellite Based Crisis Information (ZKI). When a disaster strikes, whether it is a flood, earthquake or explosion, the ZKI quickly compiles Earth observation data and other geodata to create situation information. This data provides a comprehensive overview of conditions before, during and after the disaster, supplying authorities and relief organisations with up-to-date maps and information for their operations. The ZKI is also involved in the planning for major events. Monika Gähler, who leads ZKI as part of the DLR Earth Observation Center, explains, "Satellite data offers great added value in the event of flooding, for example. We can use radar technology to see through clouds and get a clear picture of the flood situation." Additionally, aerial images are captured and made available to key parties, as was done in early summer 2024 when parts of southern Germany were flooded. In this instance, artificial intelligence (AI) helped to identify damage.

DLR/Marc Puskeiler

ZKI is continuously evolving, generating crisis-relevant information using the latest sensors and research methods, in consultation with its users. This results in a close exchange that benefits both sides.

In Trauen, Braunschweig and Oberpfaffenhofen, it is clear that the close integration between research and development through to operational services is proving to be one of DLR's greatest strengths. This approach applies to all DLR's research areas: aeronautics, space, energy, transport and, of course, security.

Innovation boost for defence technology

Bundeswehr

Lieutenant General Gert Nultsch discusses the Innovation Management system of the German Armed Forces and how research institutions can contribute their support.

Global trends, technological developments and a security environment that is changing. The German Armed Forces have their own Innovation Management system to respond to these changes effectively. In your view, what are the biggest challenges?

We operate in a highly dynamic environment that is subject to constant change and new risks. Wars have instilled a renewed sense of urgency within the federal government for the German Armed Forces, with a clear emphasis on national and collective defence. Simultaneously, the security and defence industry requires planning stability to make investments. To achieve this, we need a creative, transparent and reliable innovation management system that ensures the German Armed Forces remain future-proof and sustainable.

Specifically, the Research and Innovation Hub (FIH) was established at the Federal Ministry of Defence (BMVg) in March of this year. The Research and Innovation Director plays a crucial role, significantly boosting the German Armed Forces' innovation capacity. This is achieved through accelerated, innovative procurement processes and an improved transition from research and technology to practical use. In addition, we are taking existing industrial strategies into consideration, focussing on realworld laboratories or a new research and innovation strategy.

DLR is also an important player in defence technology research. How important is this cooperation for the German Armed Forces?

DLR has been a reliable and competent partner for many years, be it in consulting, in the operation of joint infrastructures and facilities or in defence technology research, in which other research centres, such as the Fraunhofer-Gesellschaft and the Franco-German Research Institute in Saint-Louis, which receive a share of the basic funding from the BMVg, also play an important role. Through research, we can comprehensively analyse and evaluate new technologies, which bolsters the innovative capacity of the German Armed Forces. DLR creates synergies between security and defence research and the civilian research areas, such as aeronautics, space, transport and energy, enabling all these areas to benefit from new technological findings and scientific infrastructure.

How can DLR help the German Armed Forces and its allies respond to the global dynamics of technological development?

Given the current situation, we attach particular importance to three aspects that we associate with DLR. Firstly, DLR's expertise in overall systems, particularly in aerospace research, provides crucial Impetus for departmental research. Secondly, we need a surge of innovation in areas that have regained significance as the world undergoes significant changes. Here, we are relying on DLR's experience and expertise. Thirdly, developing certain technologies into operational capabilities will require collaboration with our partners in Europe or NATO. DLR's long-standing collaborations and established network in science, research, and industry, both at the European and transatlantic levels, will now be needed more than ever in this context.

An article by Katja Lenz from the DLRmagazine 176