Flying lighter

Getty Images/Matthew Mica Wright

"Ladies and gentlemen, we are expecting some light to moderate turbulence ahead. Please return to your seats and ensure your seatbelts are properly fastened." Frequent flyers will be familiar with this announcement, made when an aircraft flies through changing air layers or encounters stormy conditions and gusts of wind. What passengers experience as an unpleasant jolt are forces – 'loads' – acting on the structure of the aircraft, in addition to the normal stresses of flight. To withstand these forces, structures must be robust, which means relatively heavy with a trade-off in higher fuel consumption and less efficient flying. However, technology could soon address this problem – with the arrival of intelligent load control.

How does intelligent load control work?

In the DLR project oLAF (optimal load-adaptive aircraft), researchers are working to identify and reduce additional structural loads. Until now, aircraft have been built sturdy enough to passively withstand turbulence. State-of-the-art load control systems, on the other hand, operate actively: "You can imagine it like the suspension in a car that compensates for bumps in the road. While conventional shock absorbers react passively to potholes, an active, adaptive suspension system works proactively – detecting changes and compensating for them in a targeted manner. This is exactly how our system works in the air: it reacts to gusts in real time and reduces additional loads on the aircraft," explains Lars Reimer, Project Manager at the DLR Institute of Aerodynamics and Flow Technology. "By integrating this innovative load control, we can develop lighter, more efficient aircraft configurations without compromising safety, and while also improving passenger comfort."

Load control from day one

In principle, the idea of active load control is not entirely new – many types of aircraft already have Systems that counteract gusts and the loads associated with manoeuvring. However, these are usually only introduced after the basic aircraft design has been completed, when hardly any changes to the structure are possible. "In oLAF, we have integrated the technology from the very beginning of the design phase," emphasises Reimer. Using computer simulations, the project team compared a modern aircraft with current technology against a design featuring this innovative load control system. The result showed that active load control not only has the potential to make wings lighter, but also improves them aerodynamically.

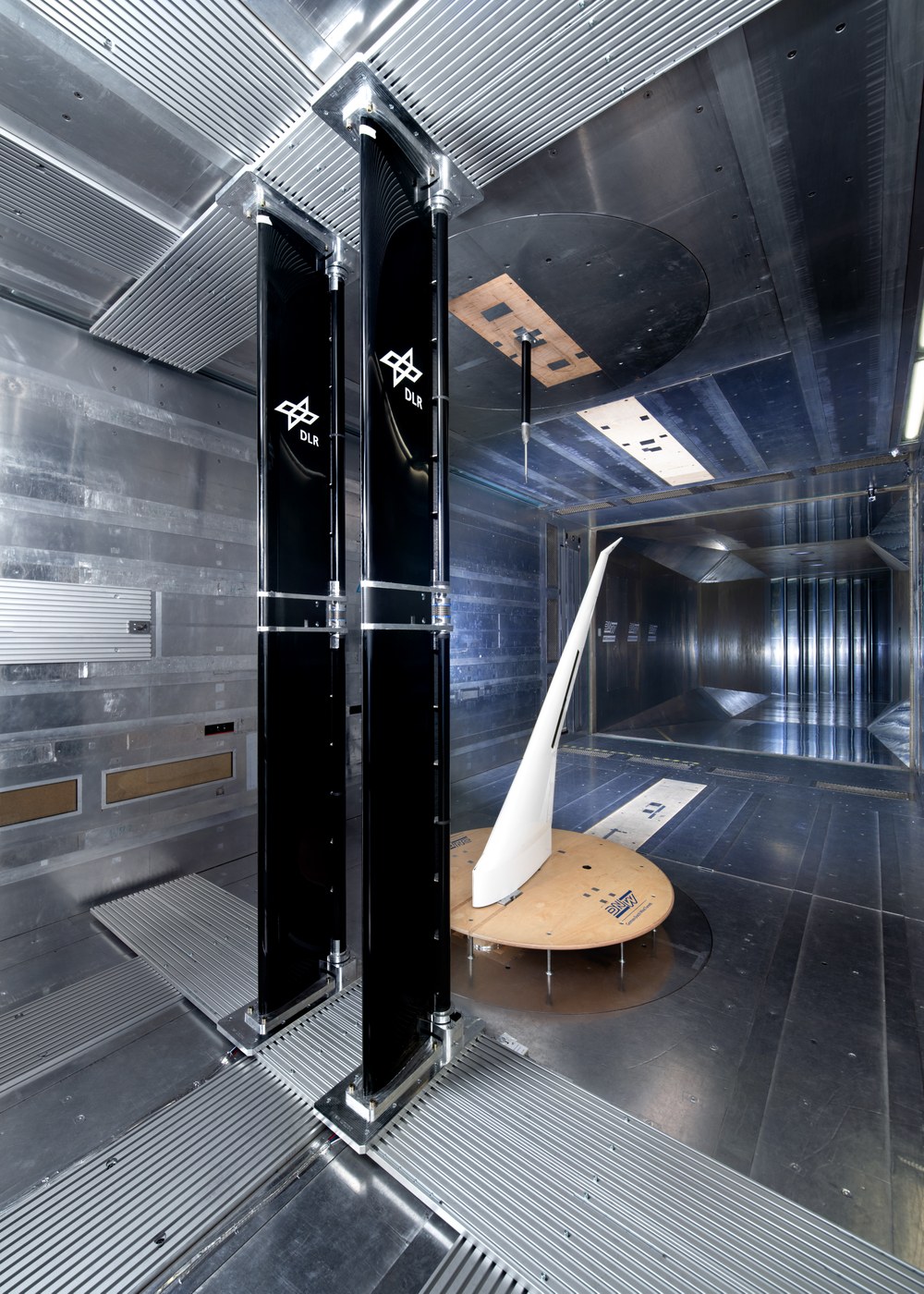

From simulation to wind tunnel

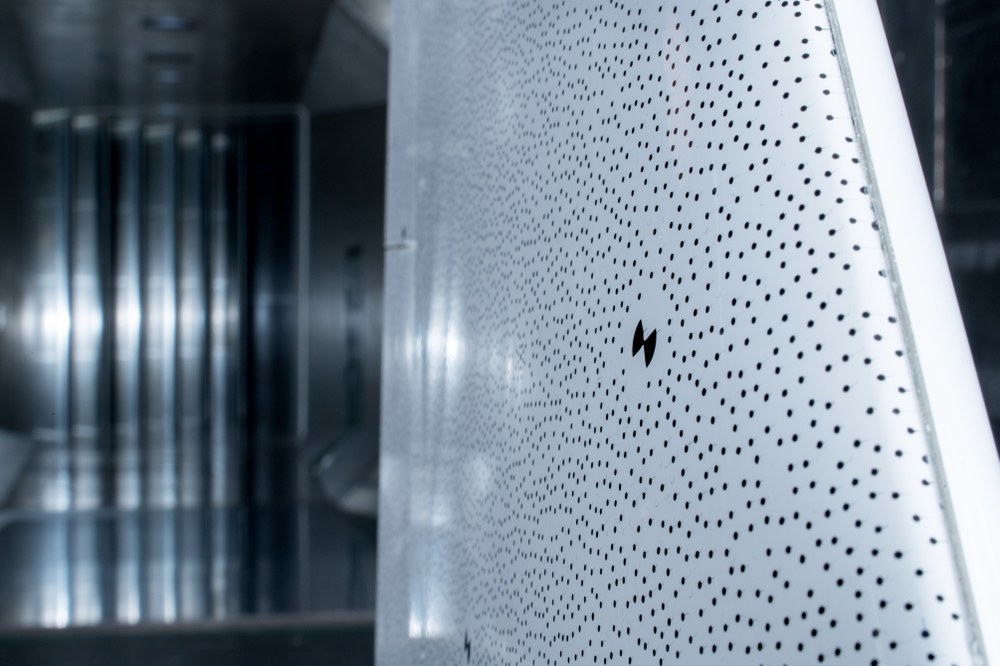

In the next step, the researchers tested a lightweight wing in a low-speed wind tunnel. "Our flexible wing was equipped with movable flaps and spoilers, which we tested using a specially developed gust generator," explains Wolf Krüger, co-project lead at the DLR Institute of Aeroelasticity. The goal was to analyse the forces acting on the wing when the trailing-edge flaps are deployed by the intelligent load control system to counteract the loads, and when they are not.

The DLR team compared the resulting oscillations of the wing under different scenarios, with and without the load control system activated. "With active load control, the wing deformed significantly less, and the load at the wing root was reduced by up to 80 percent," reports Krüger.

Economical and sustainable

The results from both simulations and tests show the great potential for savings that such systems offer. "With oLAF, we found that intelligent load control systems, if incorporated early in the aircraft design, can reduce an aircraft’s fuel consumption by up to 7.2 percent," Reimer summarises. For a typical long-haul aircraft, this equates to several tonnes of kerosene per flight – enough to save millions of euros annually and significantly reduce carbon dioxide emissions. A reduction in materials and fuel consumption not only reduces the burden on the environment but also brings economic benefits. In concrete terms, this means an increase in economic efficiency of up to seven percent due to lower consumption – even considering the potentially higher maintenance costs. "While we initially saw load control as a method for weight reduction, we now see it as a key to wings with better aerodynamics and higher efficiency," says a delighted Reimer.

From ground to air

To enable aircraft to detect turbulence before entering bumpy air, the next project phase will see load reduction technology take to the skies, including on DLR's ISTAR research aircraft. The ISTAR aircraft is equipped with LiDAR (Light Detection and Ranging) sensors, which are able to detect wind fields well in advance. Perhaps the mid-air announcement "Please make sure your seatbelts are securely fastened" will soon be a thing of the past – thanks to intelligent load control and aircraft that think for themselves.

We initially saw load control as a method for weight reduction. Now we see it as a key to improved aerodynamics and greater efficiency.

An article by Vera Koopmann from the DLRmagazine 177