Opening up new propulsion concepts

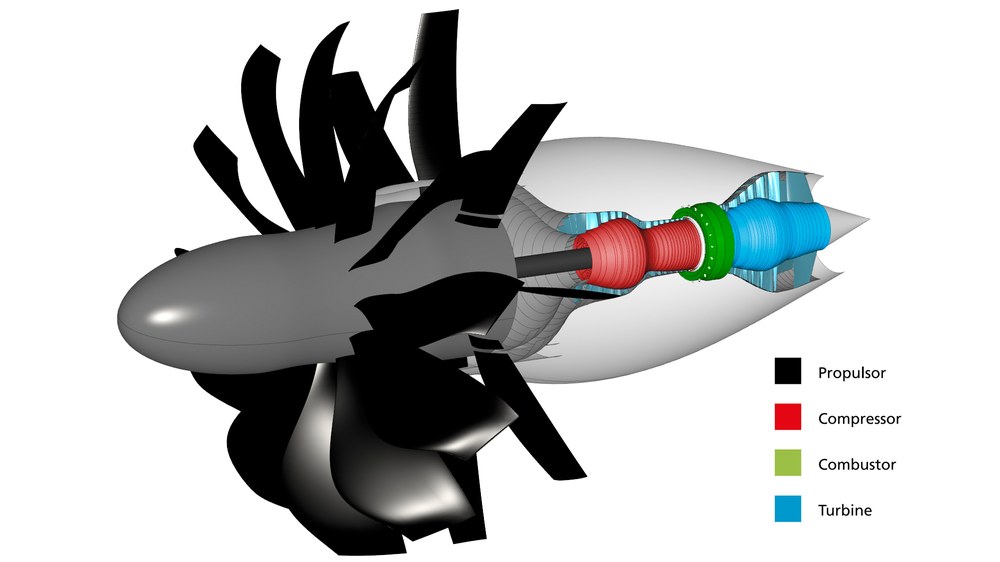

Serious engineering work on contra-rotating open rotors for aircraft propulsion dates back to the late 1940s, particularly as a means to enhance fuel efficiency and extend the endurance of long-range bombers and maritime patrol aircraft. In modern civil aviation, open contra-rotating designs gained renewed attention during the oil crisis of the 1970s as a way to reduce fuel consumption compared with conventional propellers. In 1989, General Electric's GE36 became the first demonstrator engine featuring two contra-rotating rotors, integrated into a research aircraft and tested in flight. However, projects like this were shelved when the oil crisis came to an end, and the status quo remained: propeller-driven aircraft for short-haul flights and shrouded turbofan engines for long-haul travel. Open rotors have not yet been adopted in aviation – not yet, because regardless of economic ups and downs, researchers at various DLR institutes have been exploring new approaches to engine design for around 20 years, from Contra-Rotating Open Rotor (CROR) concepts to rotor-stator combinations.

The grand objective

Today, the goal is politically driven: to reduce aviation's environmental impact by increasing efficiency. The European Union's Clean Aviation Joint Undertaking research and innovation programme stipulates, among other things, that propulsion efficiency should increase by at least 30 percent over the next 25 years compared to 2020 levels. Researchers see one way to achieve this in the further development of aircraft engines – reviving interest in the once-abandoned concept of contrarotating open rotors, a technology that is particularly promising for use in medium-range aircraft.

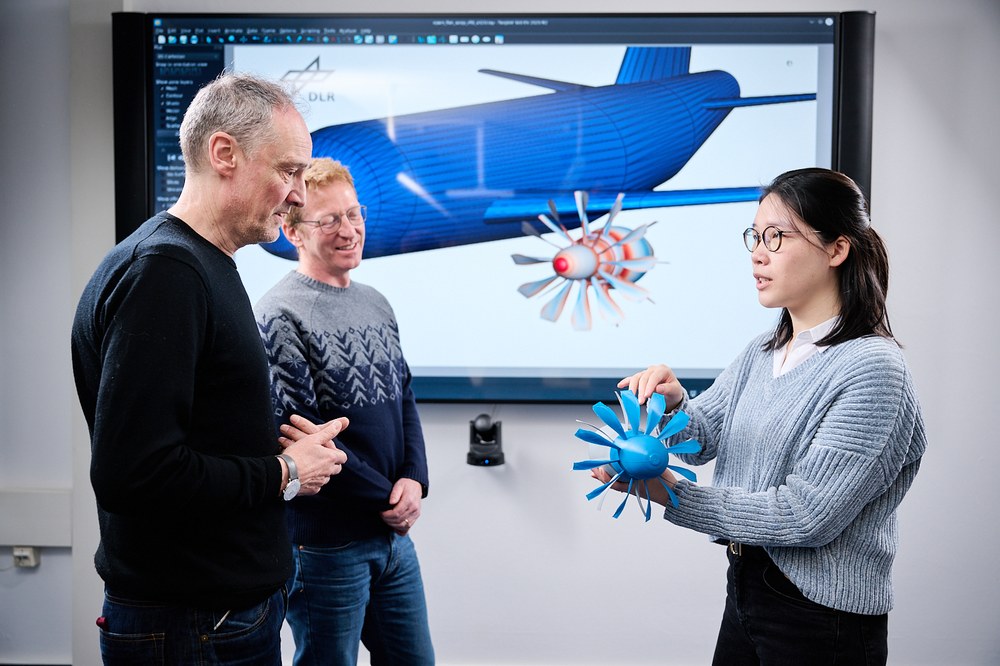

At the DLR Institutes of Propulsion Technology in Cologne and Aerodynamics and Flow Technology in Braunschweig, researchers are exploring open rotor designs across several projects. Their work spans classic propellers (turboprops), contra-rotating open concepts (propfans) and shrouded designs (turbofans).

Open versus shrouded

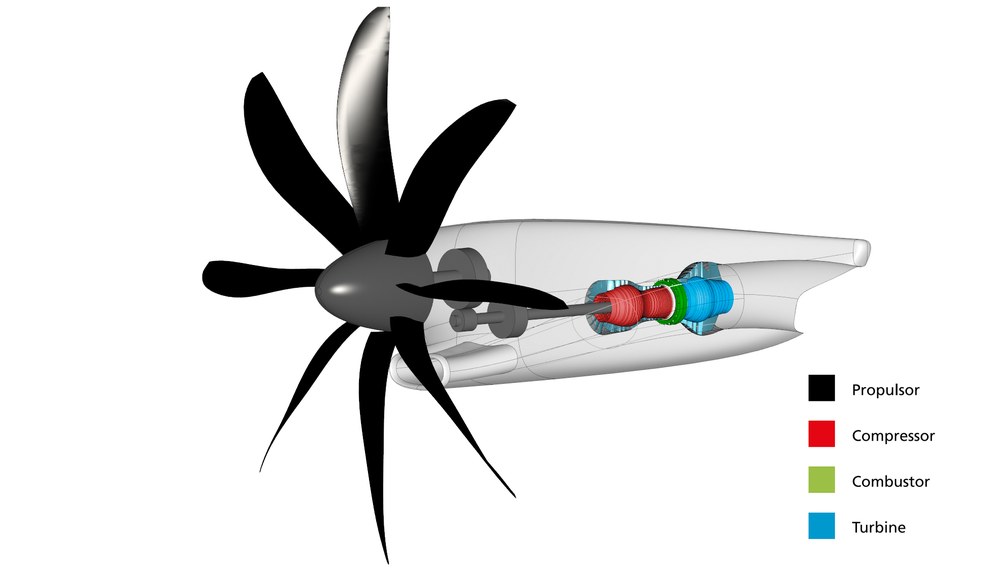

The situation is complex: different aircraft require different types of engines, so there is no one-size-fits-all approach to improving efficiency. For short-haul flights carrying up to 50 passengers, propeller-driven aircraft remain the preferred option, cruising at approximately 500 kilometres per hour. If longer distances are involved, where passengers require more space, an aircraft needs to fly faster. An Airbus A320, for instance, typically carries around 180 passengers and cruises at approximately 750 kilometres per hour – speeds that conventional propellers (turboprops) cannot achieve. While turboprops are generally more efficient than turbofans, their propulsion efficiency declines significantly at high speeds.

This is why turbofans – the familiar, shrouded jet engines – are used for medium- and long-haul routes. To generate the same thrust as an A320's two-metre-diameter turbofan engine, a conventional turboprop would theoretically need to be so large that it wouldn't fit beneath or above the wings. It would also be nearly impossible to integrate it with the tailcone. A smaller propeller could compensate by turning much faster to produce the required thrust. However, rotor blade speeds can only be increased up to a certain point, beyond which the mechanical load on the rotor blades becomes excessive, reducing efficiency and increasing noise.

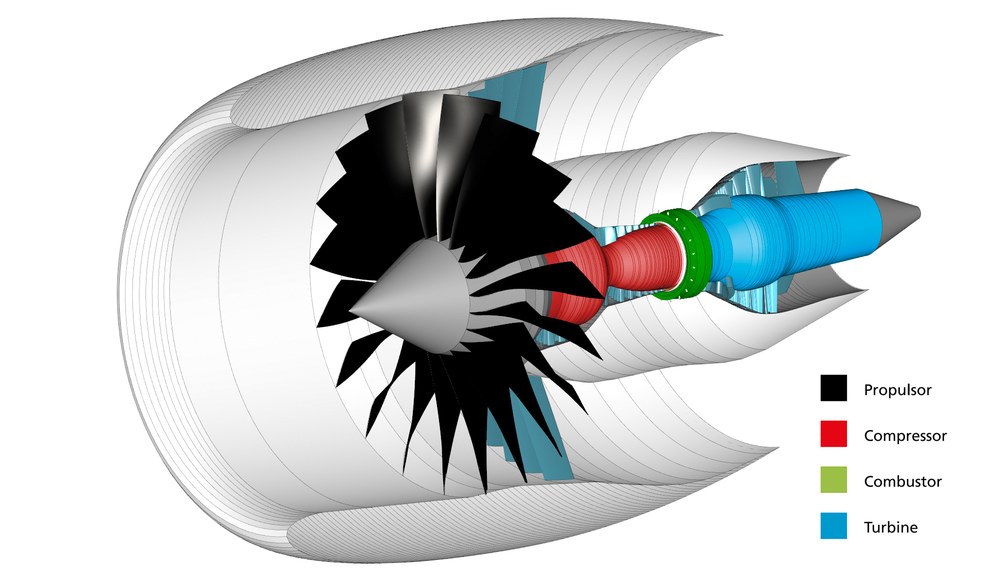

Dilemma solved

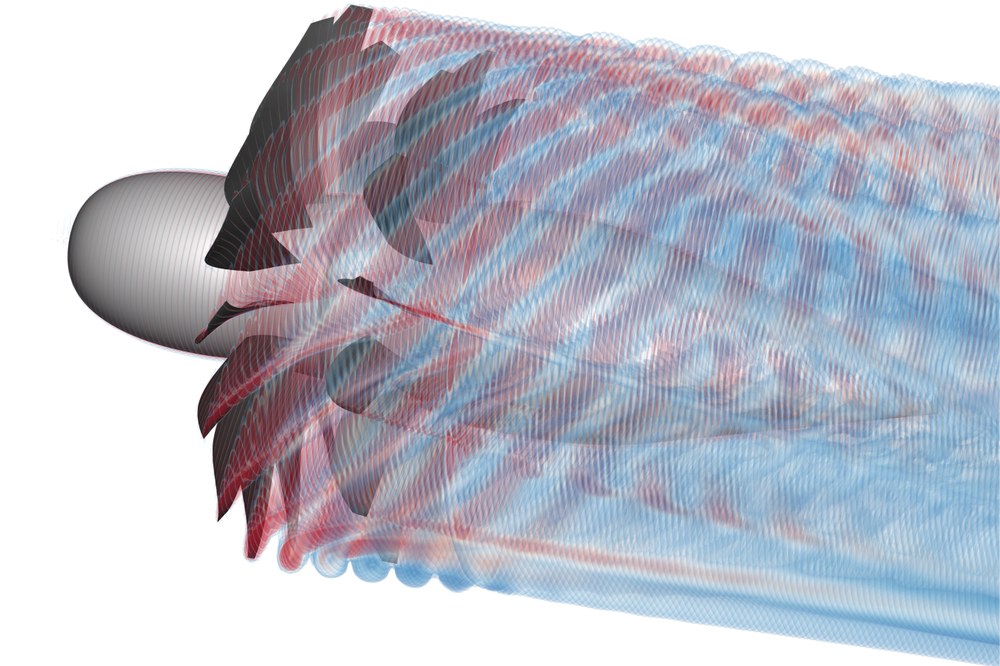

To address this, researchers devised a way to convert the otherwise-wasted swirl energy into thrust – similar in principle to how braking energy in cars is repurposed for propulsion. In the new open-fan concept, a rotor was developed with blades specifically designed for high speeds to prevent such energy losses. A stator – with non-rotating blades – positioned downstream of the rotor, captures and converts the swirl energy into additional thrust. This approach makes the system even more efficient than a comparable turbofan engine, partly because eliminating the fan casing reduces drag.

However, this concept also significantly loses efficiency at speeds above 800 kilometres per hour due to increasing frictional forces. A conventional gas turbine core engine is needed to drive open rotors. This must be small and highly efficient at the same time – a challenge that the DLR Institute of Propulsion Technology is dedicated to addressing.

Even under strongly varying wind loads, the rotor must remain stable at all times

Noise emissions and aerodynamic integration

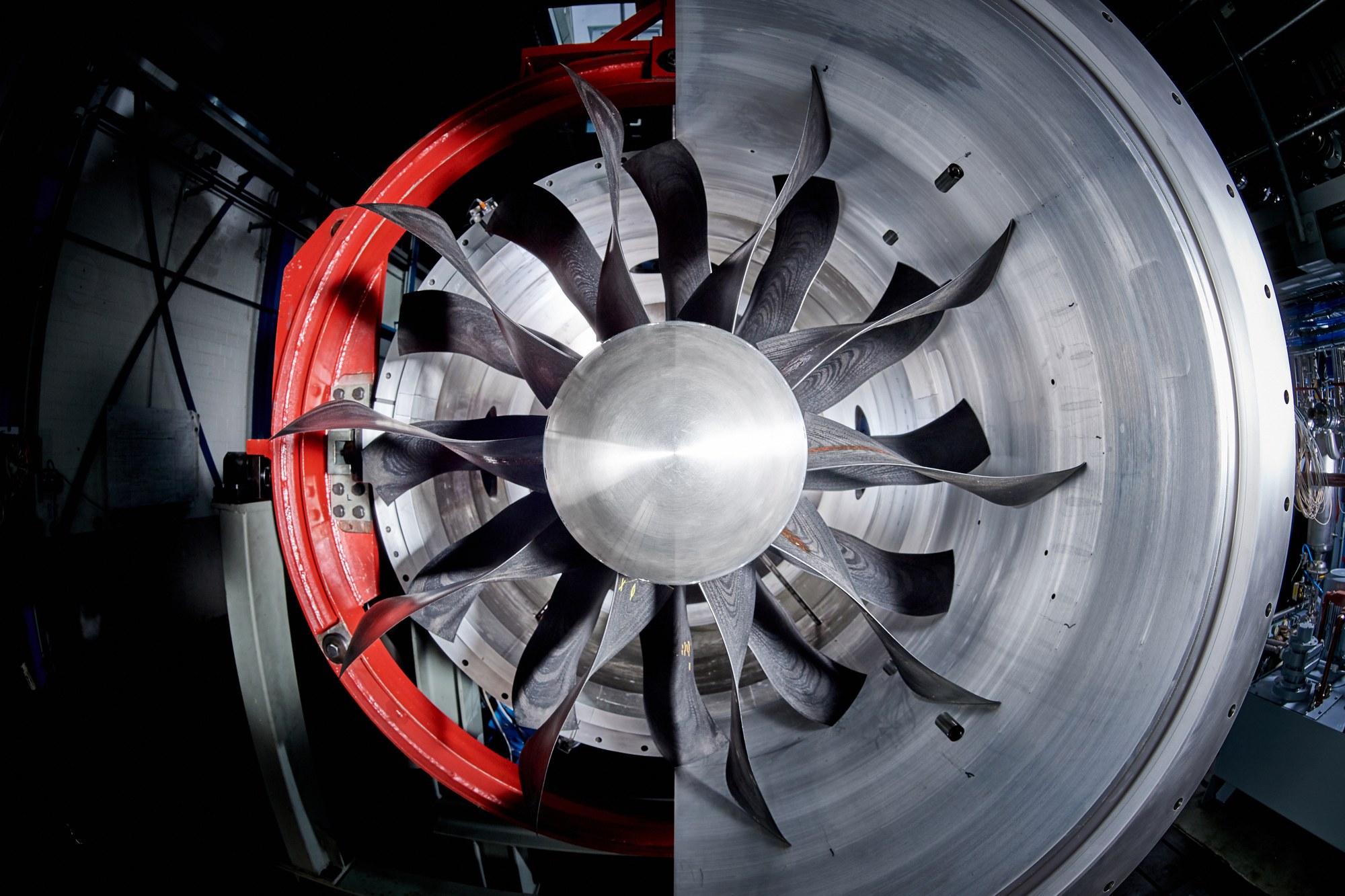

As part of the EU project PANDORA, and under the lead of Universidad Politécnica de Madrid, DLR researchers – working together with consortium members Safran Aircraft Engines as well as École Centrale de Lyon and Imperial College London – are developing a new rotor-stator concept. Initially, they designed the structure and performance of the engine using novel, highly advanced numerical algorithms in virtual computer models. They are now constructing a model to be tested in the aeroacoustic low-speed wind tunnel at DLR's site in Braunschweig, operated by the German-Dutch Wind Tunnels Foundation.

But power and efficiency are only part of the mission; noise and aerodynamic integration present significant challenges for propulsion engineers and aerodynamicists. Rainer Schnell from the Institute of Propulsion Technology explains: "Without the shroud, a lot of protection is lost. That's why our research focuses on designing an open rotor that remains structurally stable in all flight conditions. It must also produce no more noise than today's jet engines while being highly efficient during long-distance cruising."

Certification requirements must also be met, which influences key design decisions. Rotor blades, for instance, must meet minimum thickness standards for structural stability, which comes at the expense of efficiency. The rotor's behaviour across different flight phases is another critical factor. Carola Rovira Sala from the Institute of Propulsion Technology highlights this challenge: "During take-off, the angle of attack – the angle at which air flows into the engine – can reach up to 20 degrees. Even under strongly varying wind loads, the rotor must remain stable at all times."

Individually adjustable stator blades

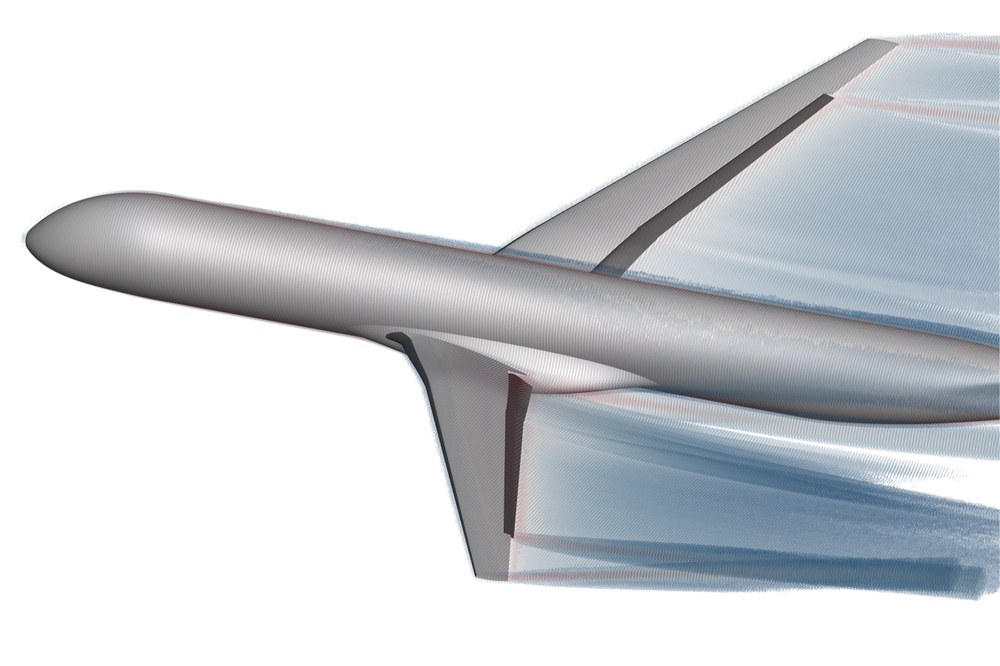

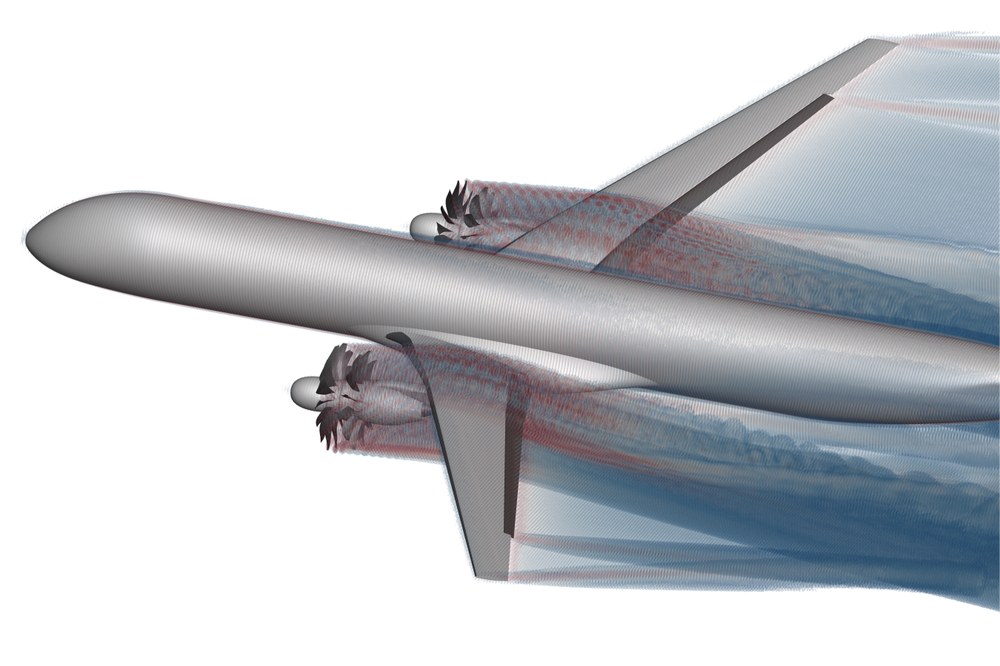

For propulsion systems featuring open rotors or propellers, careful consideration of the aerodynamic effects caused by their integration into the overall aircraft design is essential. As part of the European research programme Clean Sky 2, the DLR Institute of Aerodynamics and Flow Technology is collaborating with Airbus and Safran to investigate how different open-rotor concepts affect airflow around the wings and engine mounts – particularly in terms of lift and drag. Researchers first analysed the engine’s behaviour in isolation, then at various angles of attack. Using specialised flow simulation software, they began by modelling the aerodynamics of a complete, non-powered aircraft design on a computer. They then introduced virtual engine nacelles beneath the wings – initially without rotor blades, then with blades and, finally, with thrust applied.

During these simulations, one issue quickly became apparent: at high angles of attack, such as those experienced during take-off, the aerodynamic performance of some of the stator blades was adversely affected. This could impact the overall efficiency of the engine and lead to vibrations and noise.

This finding prompted Arne Stürmer and his team at the Institute of Aerodynamics and Flow Technology to rethink the stator configuration for the open-fan propulsion system. Rather than setting all stator blades at the same pitch angle, they are now exploring a design in which each blade has an individually optimised angle. This adjustment aims to mitigate unfavourable aerodynamic effects at high angles of attack and improve overall propulsion system efficiency.

These findings underscore the importance of early simulations when developing new aircraft and propulsion systems. By identifying aerodynamic challenges early on, researchers can implement targeted solutions before moving to physical prototypes

Compromise – the key to success

For both an open-fan engine and propeller-driven aircraft, the direction of rotor rotation is an important design choice. In an engine manufacturer's ideal world, each aircraft wing would have an engine with rotors turning in the same direction. The advantage? Only one type of engine would need to be certified.

However, a symmetrical design – with the rotors on each wing turning in opposite directions – has advantages in terms of the overall aerodynamic performance of the aircraft. But this comes with higher costs both in production and maintenance, as separate spare parts – such as rotor blades – must be stocked for both the left and right engines. In theory, the stator could fully recover the swirl and thereby eliminate the impact of rotor rotation on the wing. This requires appropriate studies on stator design.

Arne Stürmer concludes on the complex integration of the propulsion system: "With open rotors, the most aerodynamically efficient position for the propulsion system almost never aligns with the most efficient design for the aircraft body. Everyone involved must work together to find the best compromise for the overall system."

Theory and practice

As the development of open rotor-stator designs progresses, DLR experts agree that computer simulations – no matter how advanced – are not sufficient on their own. Real-world testing is essential. Last year, initial wind tunnel trials were carried out in a collaboration between Airbus and Safran – a promising first step toward making the next generation of passenger aircraft powered by open fan engines a reality. At the end of 2025, a new cooperation project between DLR and Airbus will begin, focusing on the low-noise, efficient integration of an open fan into an aircraft. This will take the open-fan concept from the computer and into the wind tunnel.

An article by Michael Müller from the DLRmagazine 177