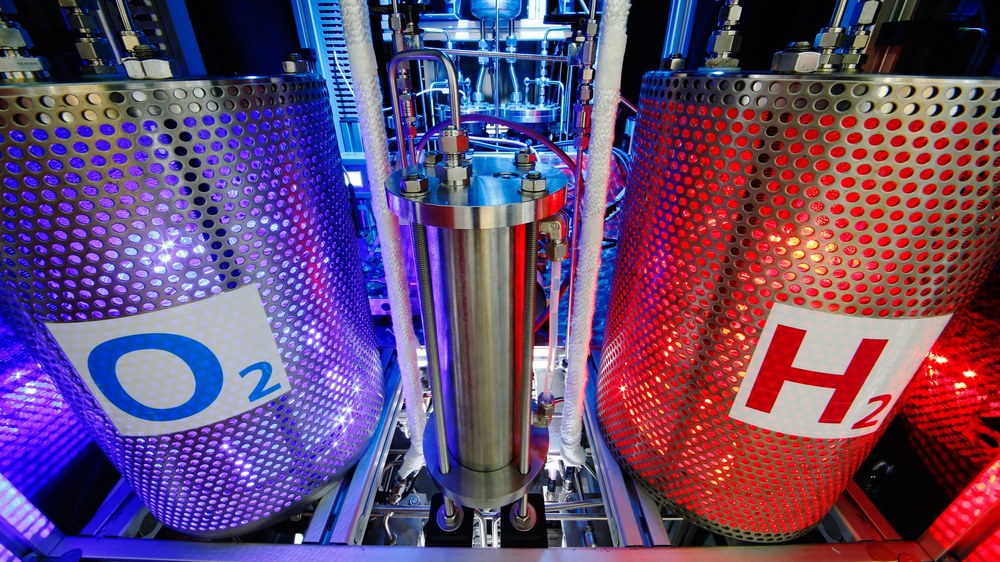

Fuel cells and electrolysis

Hydrogen fuel cells are highly efficient. They use hydrogen and oxygen to produce electricity and heat. Electrolysers reverse this process. They split water into hydrogen and oxygen with the help of electrical energy. Technically speaking, electrolysers and fuel cells are thus closely related.

DLR's work on fuel cells includes the development of components and the so-called stacks – these are the heart of a fuel cell system. DLR is conducting research on polymer electrolyte fuel cells (PEFC) and solid oxide fuel cells (SOFC), as well as improving electrolysis processes for the production of hydrogen. It is working on electrolysers with proton exchange membranes (PEM), on alkaline electrolysis and on solid oxide electrolyser cells (SOEC).At DLR, research is also being conducted into solar high-temperature processes to produce hydrogen.

From electrochemical fundamentals to application in the energy and mobility sector

The activities in the field of fuel cells and electrolysis are primarily based at the DLR Institute of Engineering Thermodynamics. Together with DLR institutes from the research fields of energy, transport, aeronautics and space, the Institute is laying the foundations for bringing hydrogen technologies into application. Demonstrators for road, rail, water and air vehicles are created in cooperation with industry. DLR thus covers the entire process chain in the field of electrochemistry: from algorithms for electrochemical simulations on quantum computers to laboratory experiments and the development of prototypes.

Solutions for practical applications: efficient, robust, cost-effective and sustainable

The goal of the research activities is to devise efficient, robust and cost-effective solutions for practical applications. The use of sustainable materials plays an important role here to enable the production of large quantities. In order to extend the service life, DLR uses the latest diagnostic techniques and develops them further. This makes it possible to detect weak points in operation at an early stage and reliably. Furthermore, they are investigating coating techniques to develop highly effective reaction surfaces for fuel cells and electrolysers.