The EDEN ISS greenhouse

LIQUIFER

LIQUIFER Systems Group

How can humans be supplied with fresh vegetables and fruit during space missions, whether on board a spacecraft or even on the Moon or Mars? This was the focus of the EDEN ISS project, which used a specially developed Mobile Test Facility (MTF). From 2018, the facility underwent testing in Antarctica to make the production of food and other important resources such as oxygen and water possible in a hostile environment. The goal was to test the key technologies required for this and develop operational procedures. Scientific questions related to plant cultivation were also investigated. EDEN ISS was also used to research future food production in areas with an unfavourable climate, such as deserts and arctic regions.

The project focused on cultivating plants that have a high water content and therefore cannot be stored for a long time without suffering significant losses in quality. The crops grown included tomatoes, peppers, cucumbers, various types of lettuce, radishes, spinach, various herbs (basil, chives, parsley, mint, coriander) and strawberries.

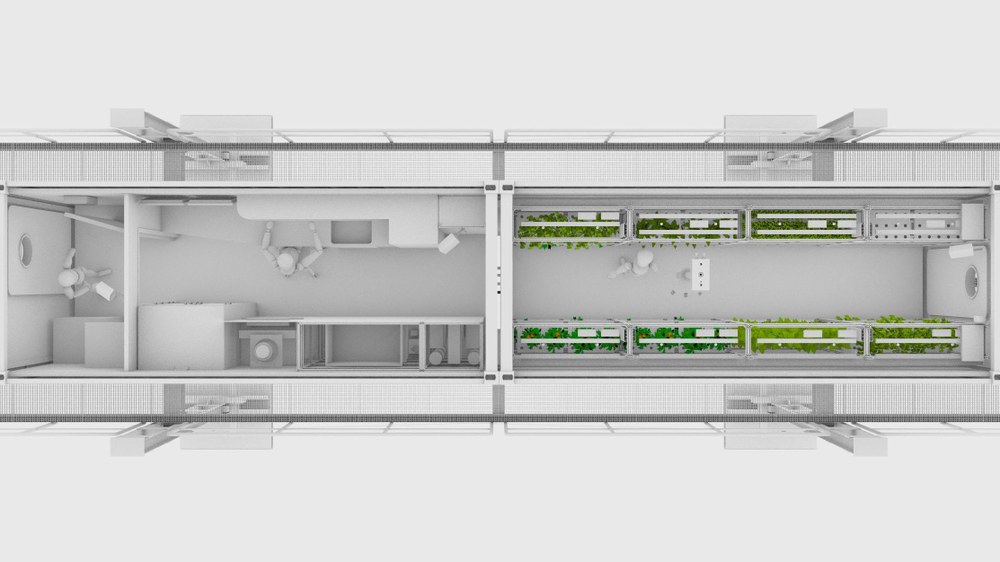

The EDEN ISS MTF consisted of two rectangular containers approximately six metres long, which were divided into three different sections:

- Future Exploration Greenhouse (FEG) – the plant growing area of the MTF, which included multilevel plant growth racks operated in a precisely controlled environment.

- Service area – housed systems for greenhouse control, air and heat management, the nutrient supply system, and a workstation for pre- and post-harvest preparation.

- Airlock – a small room that provided storage and an air buffer to limit the entry of cold air when the main access door of the facility was opened.

The EDEN ISS project developed an advanced nutrient delivery system, a high-power LED lighting system, a bio-detection and decontamination system and food quality and safety processes and technologies.

The primary goal was to achieve highly reliable plant cultivation systems with maximum biomass output from plants with high water content, produced in a resource-efficient way (energy, water, nutrients) and with high plant densities.

Plant cultivation without soil, with optimised light and carbon dioxide concentration and using a closed water circuit

The special feature of the EDEN ISS greenhouse is that it was an almost entirely closed system. All the resources needed to cultivate plants came from the plants themselves – including air, nutrients, water and energy.

By carefully controlling the environmental conditions in the greenhouse, the development of the plants could be influenced so that they had a very high nutrient content.

The plants in the EDEN ISS greenhouse were cultivated using aeroponics. Using this technology, plants are cultivated without soil; their roots hang in closed containers and are sprayed every few minutes with a computer-controlled water/nutrient mixture. A very special nutrient solution was developed for EDEN ISS that was precisely tailored to the needs of the plants.

Light is crucial for optimal plant growth. Plants need it for photosynthesis, the process whereby they convert light energy and carbon dioxide from the atmosphere into sugar, which they need to grow and produce fruit. In a greenhouse, the light must be evenly distributed so that it reaches all the plants equally well. The EDEN ISS greenhouse used a LED system developed specifically for this purpose. It covered only the light spectrum that the plants needed for photosynthesis – mainly red and a little blue – and was thus energy efficient.

The temperature in the EDEN ISS greenhouse was between 20 and 25 degrees Celsius. This temperature is ideal to support the physiological processes of the plants, such as photosynthesis, water transport and evaporation. The heat in such a closed system was mainly generated by the light sources. The water released by the plants into the air was collected and fed back into the system.

The air in the greenhouse was also treated. It had a slightly increased carbon dioxide content, and special filters to remove traces of fungus and germs. In addition, a system sterilised the air using ultraviolet radiation. This made it possible to grow plants without using insecticides and pesticides.

The EDEN ISS greenhouse could also be operated from a distant control room. For this purpose, the project was continuously improving remote diagnosis through image monitoring.

A secure system with produce that is safe to consume

If such a plant cultivation system is to be used on crewed missions, it must be extensively tested in advance. For example, no water may leak from the greenhouse. But the most important thing is that the food produced is safe to consume: any presence of bacteria or fungi that could endanger the health of the crew or the plants must be ruled out.

The technologies developed here for future long-term crewed missions can also optimise greenhouses on Earth in terms of the resources used, the costs and the quality of the food produced. Based on this, special greenhouse systems that require very little water could be developed for use in regions such as deserts. In addition, the knowledge gained from the project can be used to reduce the use of pesticides and to improve the quality of food produced.